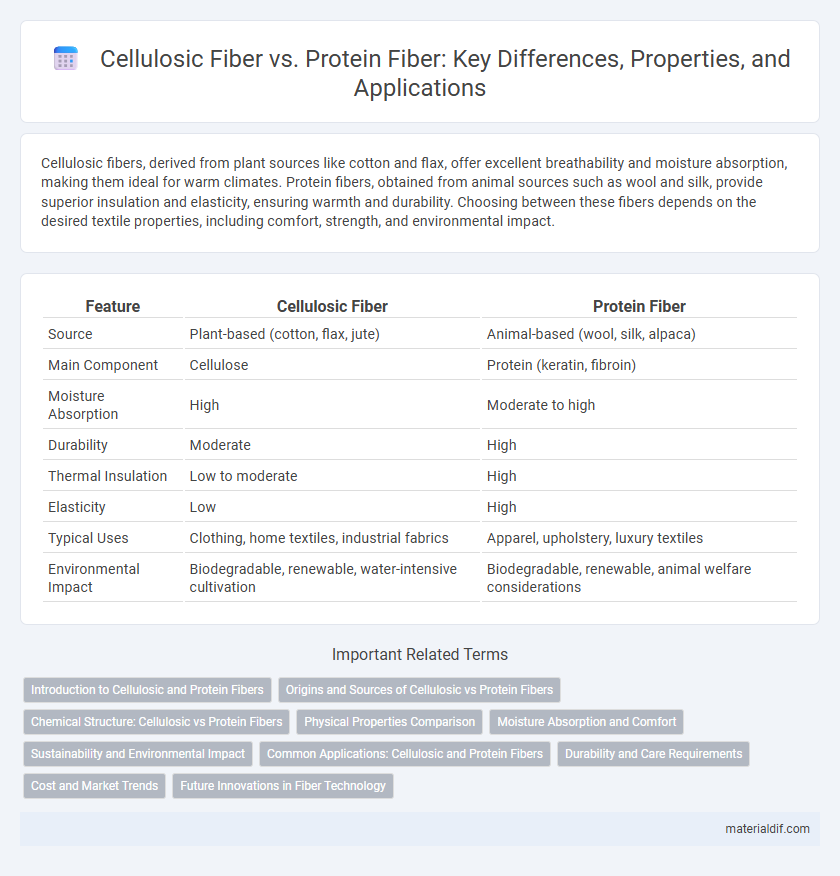

Cellulosic fibers, derived from plant sources like cotton and flax, offer excellent breathability and moisture absorption, making them ideal for warm climates. Protein fibers, obtained from animal sources such as wool and silk, provide superior insulation and elasticity, ensuring warmth and durability. Choosing between these fibers depends on the desired textile properties, including comfort, strength, and environmental impact.

Table of Comparison

| Feature | Cellulosic Fiber | Protein Fiber |

|---|---|---|

| Source | Plant-based (cotton, flax, jute) | Animal-based (wool, silk, alpaca) |

| Main Component | Cellulose | Protein (keratin, fibroin) |

| Moisture Absorption | High | Moderate to high |

| Durability | Moderate | High |

| Thermal Insulation | Low to moderate | High |

| Elasticity | Low | High |

| Typical Uses | Clothing, home textiles, industrial fabrics | Apparel, upholstery, luxury textiles |

| Environmental Impact | Biodegradable, renewable, water-intensive cultivation | Biodegradable, renewable, animal welfare considerations |

Introduction to Cellulosic and Protein Fibers

Cellulosic fibers, derived from plant sources such as cotton, flax, and hemp, are composed primarily of cellulose, a polysaccharide that provides strength and durability. Protein fibers originate from animal sources like wool, silk, and alpaca, consisting mainly of keratin, a fibrous protein that offers elasticity and resilience. Both fiber types play crucial roles in textile manufacturing, each with unique properties suited for specific fabric applications.

Origins and Sources of Cellulosic vs Protein Fibers

Cellulosic fibers originate from plant sources such as cotton, flax, and hemp, primarily composed of cellulose, a complex carbohydrate forming the cell walls of plants. Protein fibers are derived from animal sources including wool from sheep, silk from silkworms, and hair from alpacas, composed primarily of keratin, a fibrous protein. The fundamental difference in origin lies in cellulosic fibers being plant-based and protein fibers being animal-based, influencing their physical properties and applications.

Chemical Structure: Cellulosic vs Protein Fibers

Cellulosic fibers, derived from plant sources, consist primarily of long chains of glucose molecules linked by b-1,4-glycosidic bonds, forming cellulose, a polysaccharide that provides rigidity and water absorption properties. Protein fibers, such as wool and silk, are composed of amino acid sequences forming polypeptide chains with peptide bonds, creating complex structures like keratin or fibroin that exhibit elasticity and moisture-wicking abilities. The fundamental chemical difference lies in cellulosic fibers being carbohydrate-based polymers, whereas protein fibers are made of nitrogen-containing polypeptides influencing their physical behavior and applications in textiles.

Physical Properties Comparison

Cellulosic fibers, such as cotton and linen, are characterized by high moisture absorption, excellent breathability, and moderate tensile strength, making them ideal for hot climates and comfortable wear. Protein fibers like wool and silk exhibit greater elasticity, superior warmth retention, and natural resilience, contributing to better wrinkle resistance and insulation. The physical durability of protein fibers generally surpasses that of cellulosic fibers, which tend to be more prone to degradation from sunlight and microbial attack.

Moisture Absorption and Comfort

Cellulosic fibers, derived from plant sources like cotton and linen, exhibit high moisture absorption due to their hydrophilic chemical structure, enhancing comfort by keeping the skin dry and cool in warm conditions. Protein fibers such as wool and silk have moderate moisture absorption capabilities, allowing them to retain warmth and provide insulation even when damp, contributing to comfort in cooler climates. The balance of moisture management in these fibers directly impacts wearer comfort, with cellulosic fibers preferred for breathability and protein fibers valued for thermal regulation.

Sustainability and Environmental Impact

Cellulosic fibers, derived from plant sources like cotton, flax, and hemp, offer superior sustainability due to their renewable nature and lower carbon footprint compared to protein fibers, which originate from animal sources such as wool and silk. The production of cellulosic fibers generally requires less water and emits fewer greenhouse gases than protein fibers, which involve livestock farming associated with methane emissions and higher land use. Biodegradability and recyclability further enhance cellulosic fibers' environmental profile, making them a more eco-friendly choice in textile manufacturing.

Common Applications: Cellulosic and Protein Fibers

Cellulosic fibers, derived from plant sources such as cotton, flax, and hemp, are commonly used in textiles for apparel, home furnishings, and industrial products due to their breathability and moisture absorption. Protein fibers like wool, silk, and alpaca, sourced from animal hair or secretions, find applications in high-end fashion, upholstery, and thermal insulating garments because of their elasticity and warmth retention. Both fiber types play essential roles in the textile industry, catering to diverse consumer needs through their distinctive structural and functional properties.

Durability and Care Requirements

Cellulosic fibers, such as cotton and linen, offer high durability and withstand frequent washing but may shrink or wrinkle if not cared for properly. Protein fibers like wool and silk provide excellent elasticity and strength but require gentle handling and specialized cleaning to maintain their integrity. Both fiber types demand specific care to preserve longevity, with protein fibers generally needing more delicate maintenance compared to the robust nature of cellulosic fibers.

Cost and Market Trends

Cellulosic fibers, derived primarily from plant sources like cotton and flax, generally offer a lower production cost compared to protein fibers such as wool and silk, which require animal rearing and more labor-intensive processing. Market trends indicate a growing preference for cellulosic fibers due to their sustainability and affordability, driving increased investment and consumer demand in textiles and apparel industries. Despite higher costs, protein fibers maintain a niche market for luxury and performance garments, supported by innovations in ethical sourcing and enhanced fiber quality.

Future Innovations in Fiber Technology

Future innovations in fiber technology emphasize sustainable advancements in both cellulosic and protein fibers, with researchers developing bioengineered cellulose variants that enhance durability and moisture management. Protein fibers such as silk and wool are being enhanced through genetic modification and nanotechnology to improve elasticity, antimicrobial properties, and biodegradability. These innovations aim to meet growing demands for eco-friendly textiles while advancing functional performance in apparel and industrial applications.

Cellulosic Fiber vs Protein Fiber Infographic

materialdif.com

materialdif.com