Jute fiber boasts a softer texture and greater flexibility, making it ideal for textiles and eco-friendly packaging, while sisal fiber is coarser and more durable, commonly used in ropes, mats, and brushes. The biodegradable nature of both fibers supports sustainable practices, but sisal's higher tensile strength suits heavy-duty applications better. Choosing between jute and sisal hinges on the specific requirements for softness, strength, and environmental impact.

Table of Comparison

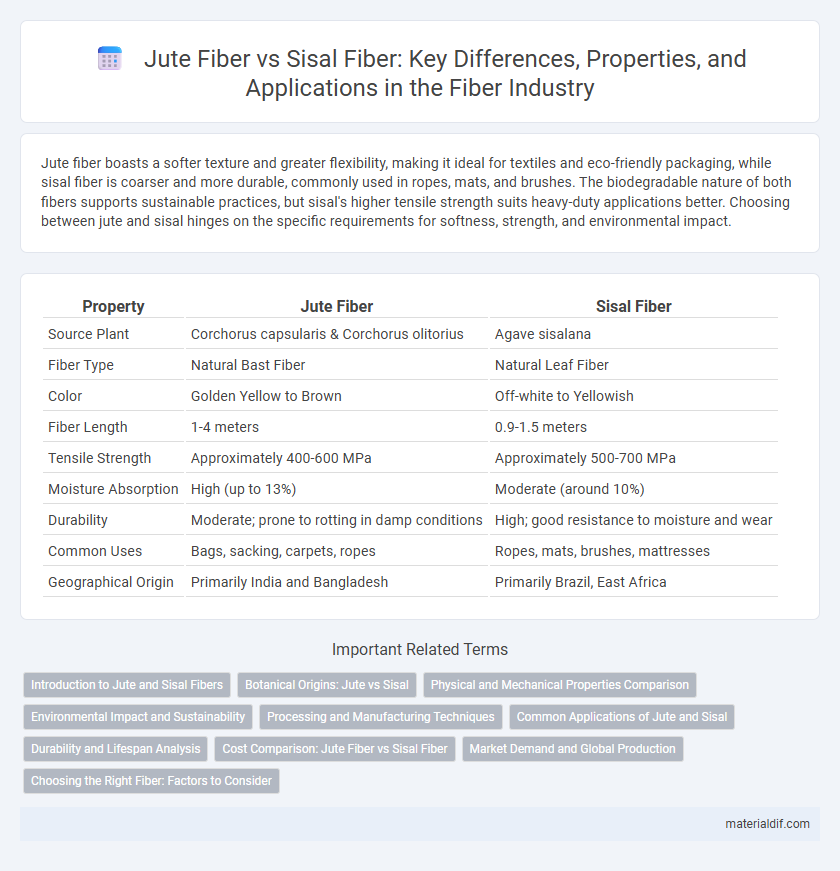

| Property | Jute Fiber | Sisal Fiber |

|---|---|---|

| Source Plant | Corchorus capsularis & Corchorus olitorius | Agave sisalana |

| Fiber Type | Natural Bast Fiber | Natural Leaf Fiber |

| Color | Golden Yellow to Brown | Off-white to Yellowish |

| Fiber Length | 1-4 meters | 0.9-1.5 meters |

| Tensile Strength | Approximately 400-600 MPa | Approximately 500-700 MPa |

| Moisture Absorption | High (up to 13%) | Moderate (around 10%) |

| Durability | Moderate; prone to rotting in damp conditions | High; good resistance to moisture and wear |

| Common Uses | Bags, sacking, carpets, ropes | Ropes, mats, brushes, mattresses |

| Geographical Origin | Primarily India and Bangladesh | Primarily Brazil, East Africa |

Introduction to Jute and Sisal Fibers

Jute fiber, derived from the bark of Corchorus plants, is known for its soft texture, biodegradability, and affordability, making it widely used in textiles and packaging. Sisal fiber, extracted from the leaves of the Agave sisalana plant, offers high durability and resistance to moisture, commonly employed in rope production and mats. Both natural fibers are renewable resources valued for their eco-friendly properties and versatile applications in sustainable industries.

Botanical Origins: Jute vs Sisal

Jute fiber is derived from the plants Corchorus olitorius and Corchorus capsularis, which belong to the Malvaceae family and thrive in warm, humid climates primarily in Bangladesh and India. Sisal fiber comes from the leaves of the Agave sisalana plant, a member of the Asparagaceae family, predominantly grown in arid and semi-arid regions such as Brazil, Tanzania, and Kenya. The botanical distinction between jute and sisal influences their fiber properties, with jute being a bast fiber extracted from the plant's stem and sisal being a leaf fiber known for its durability and coarse texture.

Physical and Mechanical Properties Comparison

Jute fiber exhibits a tensile strength ranging from 400 to 800 MPa with a density of about 1.3 g/cm3, making it softer and more lustrous compared to sisal fiber. Sisal fiber, known for its higher tensile strength of approximately 700 to 900 MPa and greater rigidity, has a density around 1.45 g/cm3, offering superior durability and resistance to wear. In terms of elongation, jute fibers typically show 1.5% to 1.8%, while sisal fibers demonstrate elongation between 2% to 3%, impacting their flexibility and suitability for diverse industrial applications.

Environmental Impact and Sustainability

Jute fiber is highly biodegradable and requires minimal pesticides, making it an eco-friendly and sustainable option with a low carbon footprint. Sisal fiber, while strong and durable, involves more intensive water and chemical use during cultivation and processing, impacting its overall environmental sustainability. Both fibers contribute to reducing plastic dependency, but jute's faster renewability and lower resource demands position it as the greener choice for sustainable textile and packaging solutions.

Processing and Manufacturing Techniques

Jute fiber processing involves retting, where stalks are soaked in water to loosen fibers, followed by stripping, washing, and drying to obtain soft, lustrous strands ideal for textiles and sacks. Sisal fiber manufacturing starts with decortication using mechanical crushers to separate fibers from leaves, then fibers are washed, dried, and brushed to improve strength and texture for ropes and mats. Both fibers require distinct methods tailored to their plant structure, impacting fiber quality and end-use applications.

Common Applications of Jute and Sisal

Jute fiber is predominantly used in the production of eco-friendly bags, carpets, rugs, and geotextiles due to its softness and biodegradability. Sisal fiber, known for its durability and resistance to moisture, is commonly employed in making ropes, mats, brushes, and upholstery. Both fibers find extensive applications in sustainable packaging and home furnishing industries, leveraging their natural strength and environmental benefits.

Durability and Lifespan Analysis

Jute fiber exhibits moderate durability with resistance to wear in dry conditions but degrades faster when exposed to moisture, limiting its lifespan primarily to indoor applications. Sisal fiber demonstrates higher durability and longer lifespan due to its robust lignin content, making it more resistant to abrasion, moisture, and microbial attack. Consequently, sisal fiber is preferred over jute for products requiring extended durability, such as outdoor mats and heavy-duty ropes.

Cost Comparison: Jute Fiber vs Sisal Fiber

Jute fiber is generally more cost-effective than sisal fiber due to its abundant availability and lower production costs, making it a preferred choice for budget-conscious applications. Sisal fiber, while more expensive, offers superior durability and resistance to wear, which can justify its higher price in specialized uses. Market prices for jute typically range between $600 to $900 per ton, whereas sisal prices often exceed $1,200 per ton, reflecting differences in cultivation and processing expenses.

Market Demand and Global Production

Jute fiber maintains higher global production volumes and widespread market demand due to its versatility in packaging and textile industries, particularly in South Asia. Sisal fiber shows strong niche demand driven by its durability and applications in automotive and construction sectors, with Brazil, Tanzania, and Kenya leading production. Market trends highlight consistent growth in jute exports alongside emerging opportunities for sisal in eco-friendly products and composites.

Choosing the Right Fiber: Factors to Consider

When choosing between jute fiber and sisal fiber, consider factors such as strength, durability, and environmental impact. Jute offers softer texture ideal for textiles and bags, while sisal provides higher tensile strength suited for ropes and mats. Assessing moisture resistance and biodegradability also plays a crucial role in selecting the right fiber for specific applications.

Jute fiber vs Sisal fiber Infographic

materialdif.com

materialdif.com