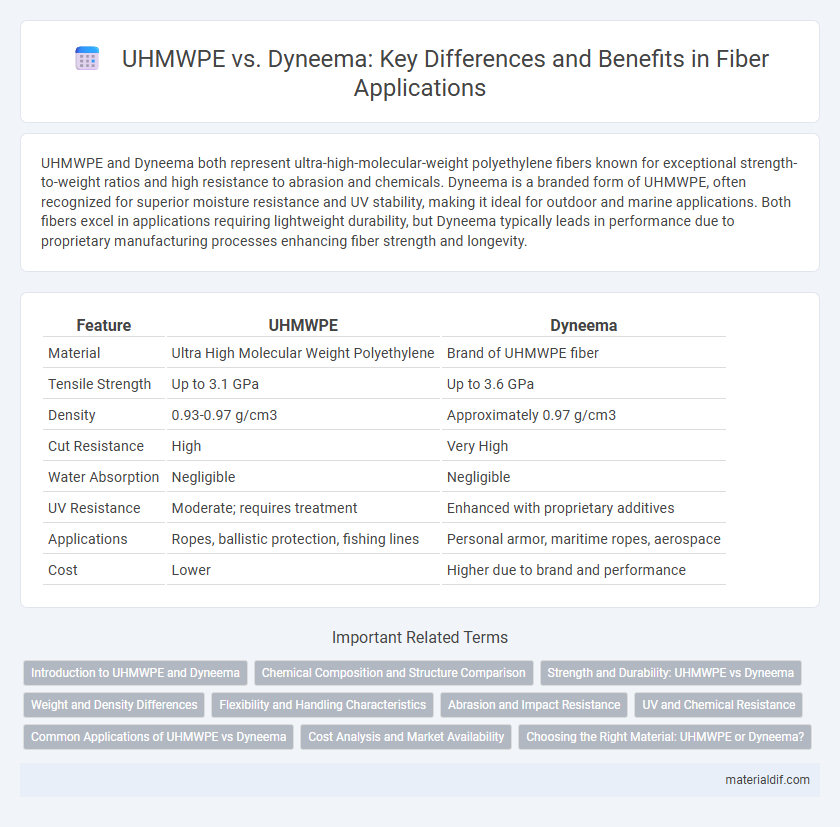

UHMWPE and Dyneema both represent ultra-high-molecular-weight polyethylene fibers known for exceptional strength-to-weight ratios and high resistance to abrasion and chemicals. Dyneema is a branded form of UHMWPE, often recognized for superior moisture resistance and UV stability, making it ideal for outdoor and marine applications. Both fibers excel in applications requiring lightweight durability, but Dyneema typically leads in performance due to proprietary manufacturing processes enhancing fiber strength and longevity.

Table of Comparison

| Feature | UHMWPE | Dyneema |

|---|---|---|

| Material | Ultra High Molecular Weight Polyethylene | Brand of UHMWPE fiber |

| Tensile Strength | Up to 3.1 GPa | Up to 3.6 GPa |

| Density | 0.93-0.97 g/cm3 | Approximately 0.97 g/cm3 |

| Cut Resistance | High | Very High |

| Water Absorption | Negligible | Negligible |

| UV Resistance | Moderate; requires treatment | Enhanced with proprietary additives |

| Applications | Ropes, ballistic protection, fishing lines | Personal armor, maritime ropes, aerospace |

| Cost | Lower | Higher due to brand and performance |

Introduction to UHMWPE and Dyneema

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene characterized by its extremely long chains, providing exceptional strength, high chemical resistance, and low weight. Dyneema is a proprietary brand of UHMWPE fiber known for its superior tensile strength and impact resistance, widely used in protective gear, ropes, and composite materials. Both UHMWPE and Dyneema offer excellent durability and are favored in applications requiring high-performance fibers with lightweight and high strength.

Chemical Composition and Structure Comparison

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) and Dyneema share a similar chemical composition, both being ultra-high molecular weight polyethylene fibers, but differ in their manufacturing process and molecular alignment. UHMWPE consists of very long polyethylene chains with minimal branching, providing high tensile strength and low density, while Dyneema is a branded UHMWPE fiber known for enhanced molecular alignment and streamlined crystallinity, resulting in superior strength-to-weight ratio and durability. The structural differences lead to Dyneema offering greater performance in applications requiring extreme strength and cut resistance.

Strength and Durability: UHMWPE vs Dyneema

Ultra-High Molecular Weight Polyethylene (UHMWPE) and Dyneema share remarkably similar strength and durability profiles, as Dyneema is a branded form of UHMWPE fiber known for its exceptional tensile strength and low weight. Both fibers exhibit outstanding resistance to abrasion, cutting, and moisture, making them ideal for high-performance applications such as ropes, ballistic protection, and composite materials. The slight variations in processing techniques and proprietary enhancements allow Dyneema to sometimes offer improved durability and consistent strength under dynamic loads compared to generic UHMWPE fibers.

Weight and Density Differences

UHMWPE (Ultra High Molecular Weight Polyethylene) and Dyneema share the same base material, but Dyneema is a branded form of UHMWPE known for its ultra-lightweight properties. UHMWPE fibers typically exhibit a density around 0.97 g/cm3, making them significantly lighter than traditional materials such as aramid or steel fibers. This low density directly contributes to Dyneema's high strength-to-weight ratio, offering superior performance in applications requiring minimal weight without sacrificing strength.

Flexibility and Handling Characteristics

UHMWPE fibers, known for their exceptional tensile strength, offer superior flexibility compared to Dyneema, making them ideal for applications requiring dynamic bending and repeated flex cycles. Dyneema, a brand of UHMWPE, is engineered for optimized handling with a smoother finish and enhanced abrasion resistance, providing excellent grip and user comfort in high-performance gear. Both fibers excel in lightweight durability, but the choice hinges on specific flexibility demands and tactile preferences during use.

Abrasion and Impact Resistance

UHMWPE fibers, such as Dyneema, are renowned for their exceptional abrasion resistance, thanks to their ultra-high molecular weight polyethylene composition. Dyneema, a branded form of UHMWPE, offers superior impact resistance compared to conventional fibers, making it ideal for ballistic protection and cut-resistant applications. Both materials demonstrate outstanding durability under high-stress conditions, but Dyneema's proprietary processing enhances its overall performance in abrasion and impact scenarios.

UV and Chemical Resistance

UHMWPE fibers and Dyneema fibers exhibit exceptional UV resistance, with Dyneema specifically engineered for enhanced resistance to ultraviolet degradation, making it highly suitable for outdoor and marine applications. Chemically, UHMWPE resists most solvents and alkaline substances, while Dyneema maintains superior resistance to acids and alkalis, providing robust performance in harsh chemical environments. Both fibers offer low moisture absorption, but Dyneema's proprietary treatments improve its durability against prolonged exposure to UV radiation and aggressive chemicals.

Common Applications of UHMWPE vs Dyneema

UHMWPE (Ultra High Molecular Weight Polyethylene) and Dyneema, a brand of UHMWPE fiber, are widely used in applications requiring exceptional strength-to-weight ratios, such as ballistic protection, cut-resistant gloves, and marine ropes. While UHMWPE fibers serve as the base material in industrial sectors including fishing nets and composite reinforcement, Dyneema's proprietary manufacturing enhances fiber tensile strength and durability, making it the preferred choice for advanced body armor and high-performance sporting equipment. Both fibers are instrumental in aerospace and medical devices where lightweight and high tensile strength are critical.

Cost Analysis and Market Availability

UHMWPE fibers, including Dyneema, dominate the market for high-performance lightweight materials, yet Dyneema generally commands a higher price due to brand recognition and proprietary manufacturing processes. Cost analysis reveals UHMWPE variants offer competitive alternatives with similar strength-to-weight ratios, attracting industries seeking budget-friendly options without significant performance trade-offs. Market availability favors Dyneema with widespread global distribution channels, while alternative UHMWPE fibers see growing presence in niche sectors and emerging markets driven by cost efficiency.

Choosing the Right Material: UHMWPE or Dyneema?

Choosing between UHMWPE and Dyneema fibers depends on specific application requirements such as strength-to-weight ratio, abrasion resistance, and cost-effectiveness. UHMWPE offers exceptional tensile strength and low abrasion, making it ideal for high-performance ropes and ballistic protection. Dyneema, a branded UHMWPE variant, provides superior durability and UV resistance, often preferred in marine and outdoor environments.

UHMWPE vs Dyneema Infographic

materialdif.com

materialdif.com