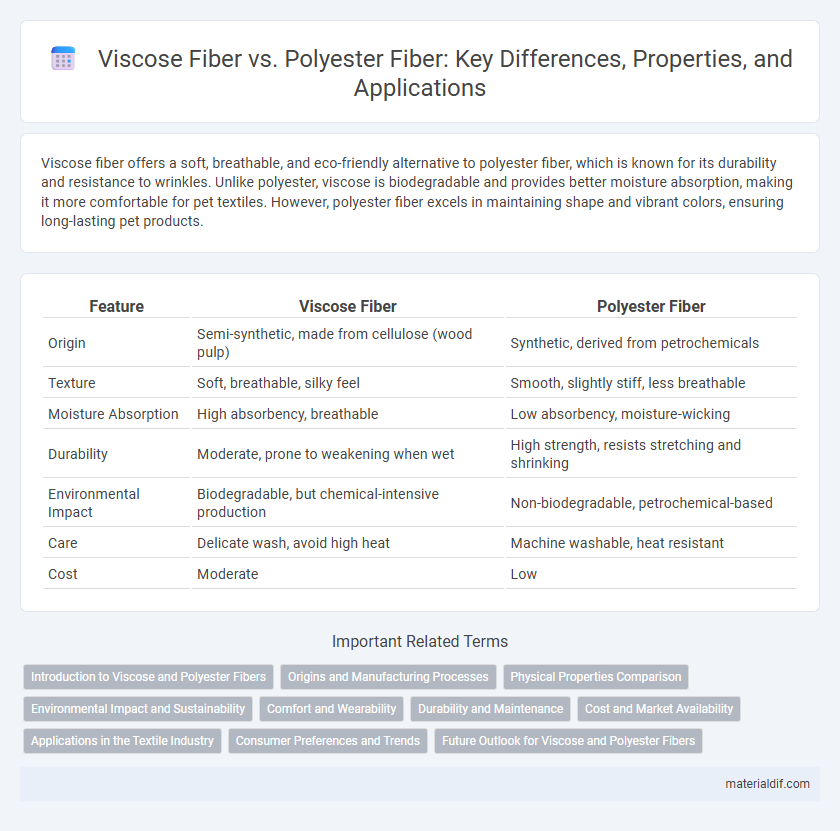

Viscose fiber offers a soft, breathable, and eco-friendly alternative to polyester fiber, which is known for its durability and resistance to wrinkles. Unlike polyester, viscose is biodegradable and provides better moisture absorption, making it more comfortable for pet textiles. However, polyester fiber excels in maintaining shape and vibrant colors, ensuring long-lasting pet products.

Table of Comparison

| Feature | Viscose Fiber | Polyester Fiber |

|---|---|---|

| Origin | Semi-synthetic, made from cellulose (wood pulp) | Synthetic, derived from petrochemicals |

| Texture | Soft, breathable, silky feel | Smooth, slightly stiff, less breathable |

| Moisture Absorption | High absorbency, breathable | Low absorbency, moisture-wicking |

| Durability | Moderate, prone to weakening when wet | High strength, resists stretching and shrinking |

| Environmental Impact | Biodegradable, but chemical-intensive production | Non-biodegradable, petrochemical-based |

| Care | Delicate wash, avoid high heat | Machine washable, heat resistant |

| Cost | Moderate | Low |

Introduction to Viscose and Polyester Fibers

Viscose fiber, derived from regenerated cellulose, offers a soft texture and excellent moisture absorption, making it ideal for breathable clothing and upholstery. Polyester fiber, a synthetic polymer made from petrochemicals, is valued for its durability, wrinkle resistance, and quick-drying properties, widely used in activewear and industrial textiles. Both fibers serve distinct purposes, with viscose prioritizing comfort and polyester emphasizing strength and longevity.

Origins and Manufacturing Processes

Viscose fiber originates from natural cellulose derived from wood pulp, undergoing a chemical process involving alkali and carbon disulfide to create a soluble compound that is spun into fibers. Polyester fiber is a synthetic polymer primarily produced from petrochemical sources through a polymerization process involving ethylene glycol and terephthalic acid, creating polyethylene terephthalate (PET). The manufacturing of viscose is more resource-intensive and involves hazardous chemicals, while polyester production relies on energy-intensive polymerization and extrusion techniques.

Physical Properties Comparison

Viscose fiber features high moisture absorbency, breathability, and a soft, smooth texture, making it comfortable for warm climates, while polyester fiber offers superior strength, elasticity, and wrinkle resistance due to its synthetic polymer composition. Viscose fibers tend to have lower tensile strength and durability compared to polyester, which exhibits excellent abrasion resistance and dimensional stability in various environmental conditions. The thermal conductivity of viscose allows for better heat retention and cooling, whereas polyester's hydrophobic nature leads to quick drying but less comfort in humid settings.

Environmental Impact and Sustainability

Viscose fiber, derived from renewable wood pulp, is biodegradable but involves intensive chemical processing that can lead to deforestation and water pollution if not managed sustainably. Polyester fiber, made from non-renewable petroleum, has a lower biodegradability rate and contributes significantly to microplastic pollution in oceans. Sustainable practices in viscose production, such as closed-loop manufacturing, reduce environmental impact, whereas recycling polyester fibers offers a route to lessen reliance on virgin fossil fuels.

Comfort and Wearability

Viscose fiber offers superior breathability and moisture absorption, making it ideal for comfortable, lightweight clothing that feels soft against the skin. Polyester fiber, while less breathable, provides excellent durability, wrinkle resistance, and quick-drying properties, enhancing wearability in active and outdoor garments. The choice between viscose and polyester fibers depends on the desired balance between natural comfort and synthetic performance.

Durability and Maintenance

Viscose fiber offers a soft, breathable texture but tends to have lower durability and requires gentle care due to its sensitivity to moisture and abrasion. Polyester fiber is highly durable, resistant to shrinking, stretching, and wrinkles, making it easy to maintain with standard machine washing and quick drying. Choosing polyester ensures long-lasting fabric performance, while viscose demands more careful handling to preserve its appearance and integrity.

Cost and Market Availability

Viscose fiber typically costs more than polyester fiber due to its natural cellulose base and more complex production process, impacting affordability for mass-market applications. Polyester fiber dominates the market availability, supported by its lower cost, higher durability, and extensive manufacturing infrastructure worldwide. The cost-effectiveness and widespread accessibility of polyester make it the preferred choice for various industries, while viscose mainly targets premium or eco-conscious segments.

Applications in the Textile Industry

Viscose fiber, known for its breathability and moisture absorption, is widely used in apparel such as shirts, dresses, and linings where comfort and drape are essential. Polyester fiber offers high durability, wrinkle resistance, and quick-drying properties, making it ideal for activewear, outerwear, and industrial textiles. The textile industry leverages viscose for its natural feel in fashion textiles, while polyester dominates in performance textiles requiring strength and longevity.

Consumer Preferences and Trends

Viscose fiber attracts consumers seeking natural, breathable fabrics with a soft texture, often preferred for sustainable fashion. Polyester fiber dominates with durability, wrinkle resistance, and affordability, making it popular in activewear and fast fashion markets. Recent trends show a growing demand for eco-friendly viscose blends, as consumers increasingly prioritize environmental impact alongside performance.

Future Outlook for Viscose and Polyester Fibers

Viscose fiber, derived from renewable cellulose sources, is gaining momentum due to increasing demand for sustainable textiles and biodegradable materials, positioning it as a key player in eco-friendly fashion and interior applications. Polyester fiber, renowned for its durability and low production costs, continues to dominate the global fiber market but faces pressure to incorporate recycled content and reduce environmental impact amid tightening regulations. Innovations in bio-based polyester and enhanced viscose production techniques signal a competitive future where both fibers evolve to meet sustainability goals and consumer expectations.

Viscose Fiber vs Polyester Fiber Infographic

materialdif.com

materialdif.com