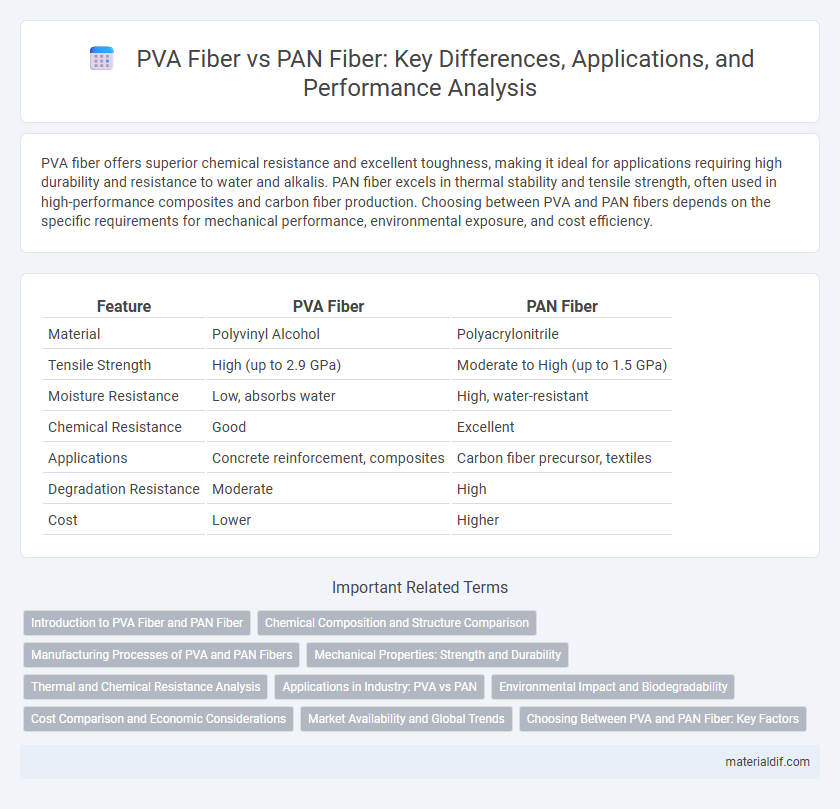

PVA fiber offers superior chemical resistance and excellent toughness, making it ideal for applications requiring high durability and resistance to water and alkalis. PAN fiber excels in thermal stability and tensile strength, often used in high-performance composites and carbon fiber production. Choosing between PVA and PAN fibers depends on the specific requirements for mechanical performance, environmental exposure, and cost efficiency.

Table of Comparison

| Feature | PVA Fiber | PAN Fiber |

|---|---|---|

| Material | Polyvinyl Alcohol | Polyacrylonitrile |

| Tensile Strength | High (up to 2.9 GPa) | Moderate to High (up to 1.5 GPa) |

| Moisture Resistance | Low, absorbs water | High, water-resistant |

| Chemical Resistance | Good | Excellent |

| Applications | Concrete reinforcement, composites | Carbon fiber precursor, textiles |

| Degradation Resistance | Moderate | High |

| Cost | Lower | Higher |

Introduction to PVA Fiber and PAN Fiber

PVA fiber is a synthetic fiber made from polyvinyl alcohol, known for its excellent tensile strength, chemical resistance, and biodegradability, making it ideal for construction and composite materials. PAN fiber, derived from polyacrylonitrile, is renowned for its high thermal stability, mechanical properties, and use as a precursor for carbon fiber manufacturing. Both fibers serve critical roles in advanced material applications, with PVA fiber favored for environmental compatibility and PAN fiber valued for its strength and heat resistance.

Chemical Composition and Structure Comparison

PVA fiber consists primarily of polyvinyl alcohol, characterized by hydroxyl groups that impart high tensile strength and chemical resistance, making it ideal for reinforcement applications. PAN fiber is composed of polyacrylonitrile with a nitrile group-rich backbone, providing excellent thermal stability and oxidative resistance due to its rigid, linear molecular structure. The chemical composition differences result in PVA fibers being more flexible and hydrophilic, while PAN fibers exhibit superior carbon fiber precursor properties with enhanced mechanical performance.

Manufacturing Processes of PVA and PAN Fibers

PVA fiber is produced through wet spinning, where polyvinyl alcohol is dissolved in a solvent and extruded into a coagulation bath to form fibers, followed by stretching to enhance strength. PAN fiber manufacturing involves solution polymerization of acrylonitrile monomers, followed by dry-jet wet spinning and high-temperature stabilization to create carbon fiber precursors. Both processes require precise control of parameters such as temperature, solvent composition, and drawing ratios to achieve optimal fiber properties.

Mechanical Properties: Strength and Durability

PVA fiber exhibits exceptional tensile strength and excellent resistance to alkalis and acids, making it highly durable in aggressive environments. PAN fiber, known for its superior modulus and high tensile strength, offers outstanding stiffness and long-term stability under mechanical loads. Both fibers enhance composite materials' mechanical performance, with PVA fibers favoring toughness and impact resistance, while PAN fibers provide greater rigidity and fatigue resistance.

Thermal and Chemical Resistance Analysis

PVA fiber exhibits superior chemical resistance, particularly against alkalis and acids, making it ideal for harsh chemical environments, while PAN fiber offers better thermal stability with a decomposition temperature typically above 300degC. The thermal degradation of PAN fibers occurs gradually, retaining structural integrity under prolonged heat exposure, whereas PVA fibers tend to degrade faster but maintain resistance to chemical solvents. Selecting between PVA and PAN fibers depends on specific application requirements, balancing the need for chemical resilience versus thermal endurance.

Applications in Industry: PVA vs PAN

PVA fiber offers superior chemical resistance and high tensile strength, making it ideal for concrete reinforcement and automotive components where durability is critical. PAN fiber excels in high-temperature environments and is widely used in aerospace and military applications due to its thermal stability and lightweight properties. Industries select PVA for structural enhancement and PAN for advanced composites requiring heat resistance.

Environmental Impact and Biodegradability

PVA fiber exhibits superior biodegradability compared to PAN fiber, breaking down more efficiently in natural environments and reducing long-term pollution. PAN fiber, derived from petroleum-based materials, has a higher environmental footprint due to its non-biodegradable nature and energy-intensive production process. Selecting PVA fiber enhances sustainability efforts by minimizing microplastic accumulation and facilitating eco-friendly disposal options.

Cost Comparison and Economic Considerations

PVA fiber typically costs more than PAN fiber due to its superior chemical resistance and higher tensile strength, making it favored in demanding applications despite the price premium. PAN fiber offers a more economical option with adequate performance in less aggressive environments, reducing overall project costs where extreme durability is not critical. Cost comparisons must factor in lifecycle expenses, as PVA fiber's longevity can offset initial investments through reduced maintenance and replacement needs.

Market Availability and Global Trends

PVA fiber, known for its high tensile strength and excellent resistance to alkali, is predominantly used in construction and industrial applications, with significant market availability in North America and Europe due to infrastructure development. PAN fiber, derived from polyacrylonitrile, dominates the carbon fiber precursor market, driving global trends toward lightweight composites in aerospace and automotive industries, especially in Asia-Pacific regions. The increasing demand for sustainable and high-performance materials fuels growth in both fibers, with PAN fiber witnessing rapid technological advancements and PVA fiber expanding through innovative construction solutions.

Choosing Between PVA and PAN Fiber: Key Factors

PVA fiber offers exceptional alkali resistance and superior bonding with cement matrices, making it ideal for concrete reinforcement in harsh environments. PAN fiber excels in thermal stability and tensile strength, favoring applications requiring high-temperature resistance and structural durability. When choosing between PVA and PAN fibers, consider factors such as chemical resistance, mechanical performance, environmental conditions, and cost-effectiveness to optimize fiber-reinforced composite outcomes.

PVA Fiber vs PAN Fiber Infographic

materialdif.com

materialdif.com