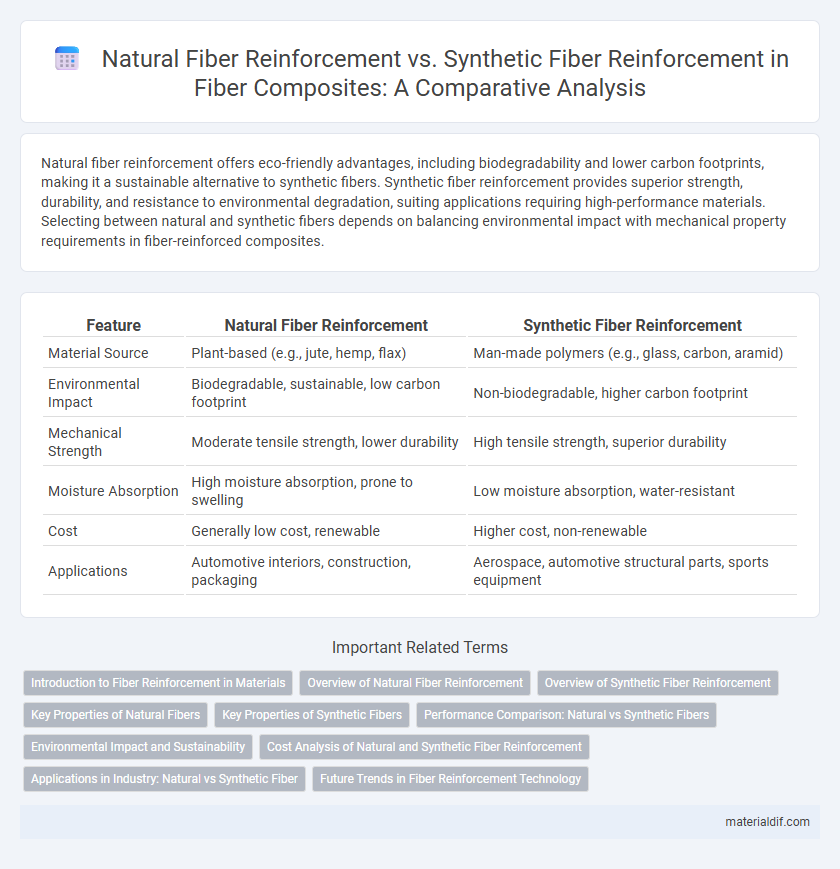

Natural fiber reinforcement offers eco-friendly advantages, including biodegradability and lower carbon footprints, making it a sustainable alternative to synthetic fibers. Synthetic fiber reinforcement provides superior strength, durability, and resistance to environmental degradation, suiting applications requiring high-performance materials. Selecting between natural and synthetic fibers depends on balancing environmental impact with mechanical property requirements in fiber-reinforced composites.

Table of Comparison

| Feature | Natural Fiber Reinforcement | Synthetic Fiber Reinforcement |

|---|---|---|

| Material Source | Plant-based (e.g., jute, hemp, flax) | Man-made polymers (e.g., glass, carbon, aramid) |

| Environmental Impact | Biodegradable, sustainable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Mechanical Strength | Moderate tensile strength, lower durability | High tensile strength, superior durability |

| Moisture Absorption | High moisture absorption, prone to swelling | Low moisture absorption, water-resistant |

| Cost | Generally low cost, renewable | Higher cost, non-renewable |

| Applications | Automotive interiors, construction, packaging | Aerospace, automotive structural parts, sports equipment |

Introduction to Fiber Reinforcement in Materials

Natural fiber reinforcement in materials offers benefits such as biodegradability, low density, and renewable sourcing, enhancing environmental sustainability. Synthetic fiber reinforcement provides superior mechanical properties, including high tensile strength, durability, and consistent quality, suitable for demanding applications. Both fiber types improve composite performance by increasing strength, stiffness, and impact resistance, with selection depending on specific material requirements and lifecycle considerations.

Overview of Natural Fiber Reinforcement

Natural fiber reinforcement utilizes fibers derived from renewable plant sources such as jute, flax, hemp, and sisal, offering eco-friendly alternatives to synthetic options. These fibers provide advantages like lower density, biodegradability, and reduced environmental impact while maintaining adequate mechanical properties for applications in automotive, construction, and packaging industries. Challenges include variability in fiber quality, moisture absorption, and compatibility with polymer matrices, which ongoing research aims to address for enhanced composite performance.

Overview of Synthetic Fiber Reinforcement

Synthetic fiber reinforcement uses man-made fibers such as polypropylene, polyester, and nylon to enhance the mechanical properties of composite materials, offering superior tensile strength, durability, and resistance to environmental degradation compared to natural fibers. These fibers provide consistent quality and performance, making them ideal for applications requiring high load-bearing capacity and long-term stability in construction, automotive, and aerospace industries. Their engineered properties enable tailored reinforcement solutions, improving crack resistance, impact absorption, and structural integrity in reinforced composites.

Key Properties of Natural Fibers

Natural fibers such as hemp, flax, and jute exhibit high tensile strength, low density, and excellent biodegradability, making them ideal for eco-friendly composite reinforcement. Their inherent moisture absorption and thermal insulation properties enhance composite materials' performance in sustainable construction and automotive applications. Compared to synthetic fibers, natural fibers also offer improved vibration damping and reduced environmental impact throughout the product lifecycle.

Key Properties of Synthetic Fibers

Synthetic fibers such as carbon, glass, and aramid exhibit high tensile strength, excellent durability, and resistance to chemicals and moisture, making them ideal for reinforcement in composite materials. Their consistent quality, low weight, and ability to be engineered for specific mechanical properties enhance structural performance in aerospace, automotive, and construction industries. Unlike natural fibers, synthetic fibers offer superior thermal stability and uniformity, contributing to longer-lasting and more reliable reinforced products.

Performance Comparison: Natural vs Synthetic Fibers

Natural fiber reinforcement offers benefits such as biodegradability, lower density, and renewable sourcing, but generally exhibits lower tensile strength and moisture resistance compared to synthetic fibers like glass or carbon fibers. Synthetic fiber reinforcement provides superior mechanical properties, enhanced durability, and consistent performance under extreme environmental conditions, making them ideal for high-performance applications. The choice between natural and synthetic fibers depends on balancing sustainability goals with required strength, stiffness, and longevity in composite materials.

Environmental Impact and Sustainability

Natural fiber reinforcement, sourced from renewable materials like hemp, flax, and jute, offers significant environmental benefits due to biodegradability and lower carbon footprint compared to synthetic fibers such as glass or carbon fibers. Synthetic fibers, while providing superior mechanical properties and durability, often involve energy-intensive manufacturing processes and generate non-biodegradable waste, raising concerns about long-term sustainability. The choice between natural and synthetic fiber reinforcement directly impacts resource consumption, recycling potential, and overall environmental footprint in composite material applications.

Cost Analysis of Natural and Synthetic Fiber Reinforcement

Natural fiber reinforcement generally offers lower material costs due to abundant availability and renewable sourcing, making it economically attractive for large-scale applications. Synthetic fiber reinforcement incurs higher expenses related to production energy, petrochemical raw materials, and specialized manufacturing processes. Cost analysis indicates natural fibers can reduce overall project budgets while synthetic fibers provide enhanced durability and performance at a premium price point.

Applications in Industry: Natural vs Synthetic Fiber

Natural fiber reinforcement excels in automotive interiors, packaging, and construction materials due to its biodegradability and lightweight properties, offering sustainable alternatives for eco-conscious industries. Synthetic fiber reinforcement dominates aerospace, sports equipment, and high-performance composites, providing superior strength, durability, and resistance to environmental factors. Industries increasingly blend natural and synthetic fibers in hybrid composites to optimize mechanical performance while reducing environmental impact.

Future Trends in Fiber Reinforcement Technology

Emerging research in fiber reinforcement technology highlights a growing shift toward sustainable natural fiber composites due to their biodegradability and lower environmental impact compared to synthetic fibers such as glass or carbon. Innovations in hybrid fiber systems integrate natural fibers with advanced synthetic materials to optimize mechanical properties and cost efficiency for automotive and construction industries. Future trends emphasize enhanced fiber surface treatments and nanotechnology applications to improve fiber-matrix adhesion and durability, driving the development of high-performance, eco-friendly composite materials.

Natural Fiber Reinforcement vs Synthetic Fiber Reinforcement Infographic

materialdif.com

materialdif.com