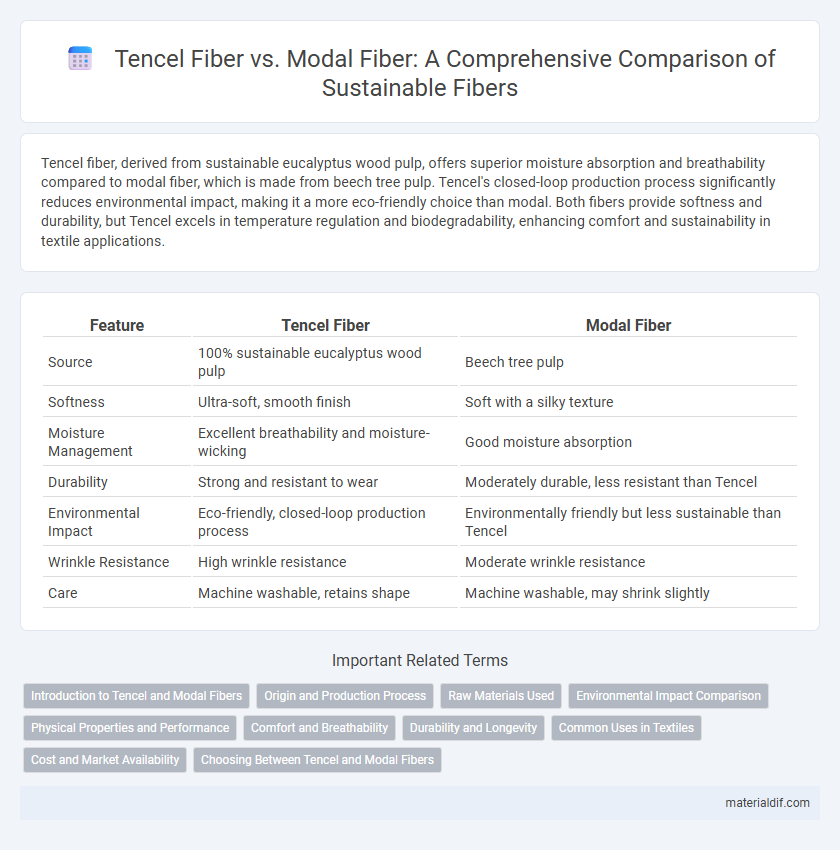

Tencel fiber, derived from sustainable eucalyptus wood pulp, offers superior moisture absorption and breathability compared to modal fiber, which is made from beech tree pulp. Tencel's closed-loop production process significantly reduces environmental impact, making it a more eco-friendly choice than modal. Both fibers provide softness and durability, but Tencel excels in temperature regulation and biodegradability, enhancing comfort and sustainability in textile applications.

Table of Comparison

| Feature | Tencel Fiber | Modal Fiber |

|---|---|---|

| Source | 100% sustainable eucalyptus wood pulp | Beech tree pulp |

| Softness | Ultra-soft, smooth finish | Soft with a silky texture |

| Moisture Management | Excellent breathability and moisture-wicking | Good moisture absorption |

| Durability | Strong and resistant to wear | Moderately durable, less resistant than Tencel |

| Environmental Impact | Eco-friendly, closed-loop production process | Environmentally friendly but less sustainable than Tencel |

| Wrinkle Resistance | High wrinkle resistance | Moderate wrinkle resistance |

| Care | Machine washable, retains shape | Machine washable, may shrink slightly |

Introduction to Tencel and Modal Fibers

Tencel fiber, derived from sustainably sourced eucalyptus wood pulp, is known for its exceptional softness, moisture-wicking properties, and eco-friendly production processes. Modal fiber, produced from beech tree cellulose, offers a smooth, breathable texture with excellent resistance to shrinkage and pilling, making it a popular choice in apparel. Both fibers are biodegradable and preferred for their comfort, durability, and minimal environmental impact compared to conventional synthetic fibers.

Origin and Production Process

Tencel fiber is derived from sustainably sourced eucalyptus wood through a closed-loop production process that recycles water and solvents, minimizing environmental impact. Modal fiber originates from beech tree pulp and undergoes a similar chemical-intensive production, though often less eco-friendly due to higher water and energy use. Both fibers are regenerated cellulosic fibers, but Tencel's lyocell process offers greater sustainability and reduced ecological footprint compared to traditional modal manufacturing.

Raw Materials Used

Tencel fiber is primarily made from sustainably sourced eucalyptus wood pulp, processed through environmentally friendly closed-loop systems that recycle solvents and minimize waste. Modal fiber is produced using beech tree pulp, utilizing a similar but less eco-efficient process that often involves more chemical treatments. The renewable wood sources for both fibers highlight their biodegradability and reduced environmental impact compared to synthetic fibers.

Environmental Impact Comparison

Tencel fiber, derived from sustainably sourced eucalyptus wood pulp, requires less water and energy in production compared to modal fiber, which is primarily made from beech tree pulp and typically involves more intensive chemical processing. Both fibers are biodegradable and produced under closed-loop systems that recycle solvents, but Tencel's manufacturing process emits fewer greenhouse gases and uses fewer harmful chemicals. This makes Tencel fiber a more environmentally friendly option with a lower overall ecological footprint than modal fiber.

Physical Properties and Performance

Tencel fiber, derived from sustainably sourced eucalyptus wood, exhibits exceptional moisture absorption and breathability, offering a soft, smooth texture that enhances comfort and durability in textiles. Modal fiber, produced primarily from beech tree pulp, is known for its high tensile strength, excellent resistance to shrinkage, and vibrant color retention after multiple washes. Both fibers provide superior softness compared to conventional cotton, but Tencel excels in moisture management while Modal delivers enhanced elasticity and dimensional stability.

Comfort and Breathability

Tencel fiber offers exceptional moisture-wicking properties and a smooth texture that enhances comfort and breathability, making it ideal for sensitive skin and activewear. Modal fiber, derived from beechwood, provides a soft hand feel and excellent air circulation but tends to retain more moisture compared to Tencel, which can affect overall freshness. Both fibers excel in softness and lightweight comfort, yet Tencel's superior breathability and moisture management give it an edge in performance fabrics.

Durability and Longevity

Tencel fiber, derived from sustainably sourced eucalyptus wood, offers superior durability due to its strong cellulose structure, resisting wear and tear better than modal fiber. Modal fiber, made from beech tree pulp, provides softness but tends to have less tensile strength and may lose shape and integrity faster after multiple washes. In terms of longevity, Tencel maintains its strength and appearance longer, making it ideal for high-performance and long-lasting textile applications.

Common Uses in Textiles

Tencel fiber is commonly used in sustainable fashion, activewear, and home textiles due to its softness, moisture-wicking properties, and eco-friendly production process. Modal fiber is popular in underwear, loungewear, and bed linens because of its breathability, silky texture, and resistance to shrinkage. Both fibers are favored for blending with cotton and synthetic materials to enhance comfort and durability in textile products.

Cost and Market Availability

Tencel fiber generally commands a higher price due to its eco-friendly production process and superior moisture-wicking properties, making it a premium choice in sustainable textiles. Modal fiber is more cost-effective and widely available in global markets, favored for its softness and durability in mass-produced apparel. Market availability of modal is greater, especially in mainstream textile industries, while Tencel is predominantly found in niche sustainable fashion segments.

Choosing Between Tencel and Modal Fibers

Tencel fibers, derived from sustainably sourced eucalyptus trees, offer superior moisture-wicking and breathability compared to modal fibers, which are made from beech tree pulp and known for their softness and durability. Choosing between Tencel and modal depends on performance needs, with Tencel favored for eco-friendly attributes and enhanced moisture management, while modal is preferred for luxurious texture and resilience. Both fibers provide environmentally conscious alternatives to traditional cotton, making them popular in sustainable fashion and activewear markets.

Tencel Fiber vs Modal Fiber Infographic

materialdif.com

materialdif.com