Regenerated fibers are produced from natural cellulose sources like wood pulp, making them more sustainable and biodegradable compared to fully synthetic manmade fibers, which are chemically synthesized from petrochemicals. Regenerated fibers such as rayon and lyocell blend natural origins with industrial processing, offering superior breathability and comfort. Manmade fibers like polyester and nylon excel in durability and moisture resistance but can contribute to microplastic pollution due to their synthetic nature.

Table of Comparison

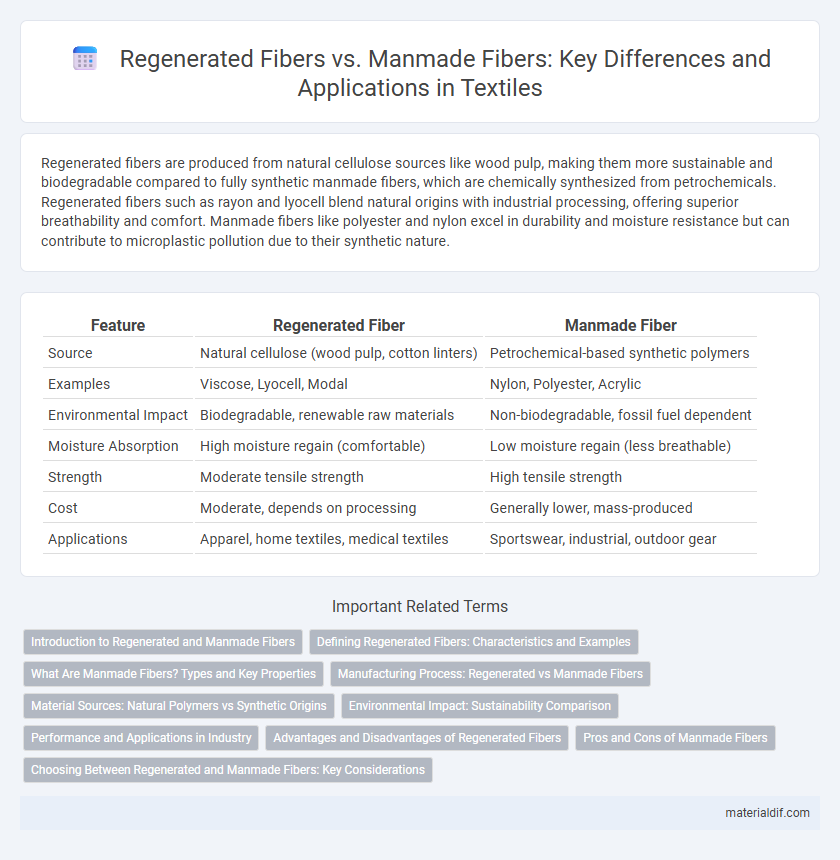

| Feature | Regenerated Fiber | Manmade Fiber |

|---|---|---|

| Source | Natural cellulose (wood pulp, cotton linters) | Petrochemical-based synthetic polymers |

| Examples | Viscose, Lyocell, Modal | Nylon, Polyester, Acrylic |

| Environmental Impact | Biodegradable, renewable raw materials | Non-biodegradable, fossil fuel dependent |

| Moisture Absorption | High moisture regain (comfortable) | Low moisture regain (less breathable) |

| Strength | Moderate tensile strength | High tensile strength |

| Cost | Moderate, depends on processing | Generally lower, mass-produced |

| Applications | Apparel, home textiles, medical textiles | Sportswear, industrial, outdoor gear |

Introduction to Regenerated and Manmade Fibers

Regenerated fibers are derived from natural polymers such as cellulose, chemically processed to create fibers like viscose, modal, and lyocell, offering a blend of natural origin and manmade performance. Manmade fibers, also known as synthetic fibers, are created from petrochemical sources through polymerization, including materials like polyester, nylon, and acrylic, known for durability and versatility. Understanding the distinction between regenerated and manmade fibers is essential for selecting textiles based on sustainability, comfort, and application properties.

Defining Regenerated Fibers: Characteristics and Examples

Regenerated fibers are produced by chemically transforming natural polymers, such as cellulose or protein, into a soluble form before spinning them into fibers, distinguishing them from fully synthetic manmade fibers derived from petrochemicals. Characterized by their biodegradability, moisture absorbency, and comfort, regenerated fibers like viscose, modal, and lyocell bridge natural and synthetic properties by combining the eco-friendly aspects of natural fibers with the versatility of manmade ones. Their applications span apparel, home textiles, and industrial uses, where sustainability and performance are prioritized over purely synthetic alternatives.

What Are Manmade Fibers? Types and Key Properties

Manmade fibers are synthetic or chemically processed fibers derived from natural materials or petroleum-based polymers, designed to mimic natural fibers while offering enhanced durability and versatility. Key types include rayon, a semi-synthetic fiber made from regenerated cellulose, and fully synthetic fibers like polyester, nylon, and acrylic, each exhibiting specific properties such as high tensile strength, elasticity, and resistance to moisture and wrinkles. These fibers are widely used in textiles due to their consistent quality, cost-effectiveness, and ability to be engineered for performance attributes like flame resistance, stretch, and moisture-wicking.

Manufacturing Process: Regenerated vs Manmade Fibers

Regenerated fibers are produced by dissolving natural polymers such as cellulose from wood pulp or cotton linters, then chemically re-spinning them into fibers through processes like viscose or lyocell production. Manmade fibers, also known as synthetic fibers, are created entirely from petrochemical sources via polymerization and extrusion techniques, exemplified by nylon, polyester, and acrylic fibers. The key manufacturing distinction lies in raw material origin: regenerated fibers are semi-synthetic, derived from natural polymers requiring chemical regeneration, whereas manmade fibers are fully synthetic, manufactured through complex chemical synthesis from fossil fuels.

Material Sources: Natural Polymers vs Synthetic Origins

Regenerated fibers derive from natural polymers such as cellulose extracted from wood pulp or cotton linters, offering a semi-synthetic alternative with biodegradability benefits. Manmade fibers are synthesized from petrochemical-based polymers like polyester and nylon, featuring high durability and versatility. The choice between them hinges on sustainability preferences and performance requirements in textile production.

Environmental Impact: Sustainability Comparison

Regenerated fibers, such as viscose and lyocell, are derived from natural cellulose sources like wood pulp, making them more biodegradable and renewable compared to fully synthetic manmade fibers like polyester and nylon, which rely on petrochemicals and contribute significantly to microplastic pollution. The production of regenerated fibers typically involves chemical processes that can impact water and air quality but innovations in closed-loop systems have improved sustainability by recycling solvents and reducing waste. Manmade fibers generally have a higher carbon footprint due to fossil fuel extraction and energy-intensive manufacturing, leading to greater environmental concerns over resource depletion and greenhouse gas emissions.

Performance and Applications in Industry

Regenerated fibers, such as viscose and lyocell, offer superior moisture absorption and breathability compared to synthetic manmade fibers like polyester and nylon, making them ideal for apparel and home textiles demanding comfort and environmental sustainability. Manmade fibers excel in strength, durability, and abrasion resistance, often used in industrial applications like ropes, filters, and automotive textiles where performance under stress and longevity are critical. The selection between regenerated and manmade fibers in industry hinges on balancing factors like biodegradability, tensile strength, and application-specific requirements, with regenerated fibers favored in eco-conscious fashion markets and manmade fibers dominating high-performance technical sectors.

Advantages and Disadvantages of Regenerated Fibers

Regenerated fibers, derived from natural polymers like cellulose, offer advantages such as biodegradability, breathability, and a soft texture that enhances wearer comfort. These fibers also tend to be more environmentally friendly than fully synthetic manmade fibers, as they originate from renewable resources and require less energy-intensive production processes. However, regenerated fibers often face disadvantages including lower durability, susceptibility to moisture absorption, and higher production costs compared to synthetic fibers like polyester or nylon.

Pros and Cons of Manmade Fibers

Manmade fibers, such as polyester and nylon, offer high durability, excellent wrinkle resistance, and cost-effectiveness, making them popular choices in the textile industry. However, they are less breathable and tend to retain odors compared to regenerated fibers like viscose or lyocell, which are more eco-friendly and biodegradable. The production of manmade fibers often involves petrochemical processes, leading to environmental concerns related to nonrenewable resources and microplastic pollution.

Choosing Between Regenerated and Manmade Fibers: Key Considerations

Choosing between regenerated and manmade fibers depends largely on environmental impact, production methods, and end-use applications. Regenerated fibers, derived from natural cellulose sources like wood pulp, offer biodegradability and a lower carbon footprint compared to fully synthetic manmade fibers such as polyester and nylon. Evaluating factors such as durability, moisture absorption, and sustainability goals helps determine the best fiber choice for textiles and industrial uses.

Regenerated Fiber vs Manmade Fiber Infographic

materialdif.com

materialdif.com