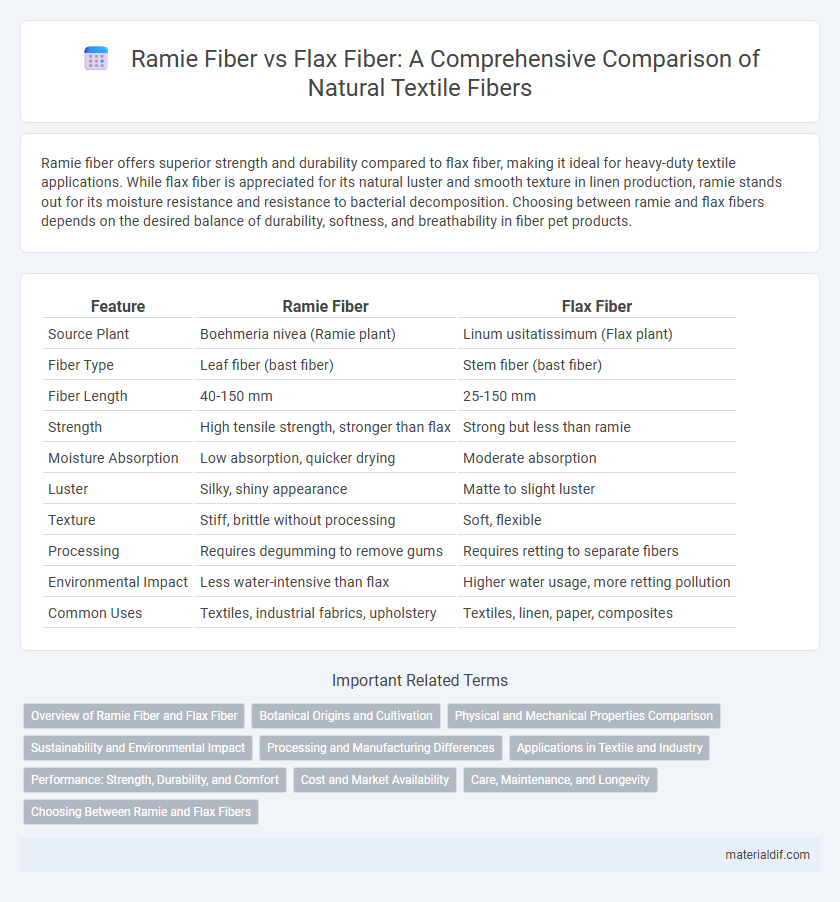

Ramie fiber offers superior strength and durability compared to flax fiber, making it ideal for heavy-duty textile applications. While flax fiber is appreciated for its natural luster and smooth texture in linen production, ramie stands out for its moisture resistance and resistance to bacterial decomposition. Choosing between ramie and flax fibers depends on the desired balance of durability, softness, and breathability in fiber pet products.

Table of Comparison

| Feature | Ramie Fiber | Flax Fiber |

|---|---|---|

| Source Plant | Boehmeria nivea (Ramie plant) | Linum usitatissimum (Flax plant) |

| Fiber Type | Leaf fiber (bast fiber) | Stem fiber (bast fiber) |

| Fiber Length | 40-150 mm | 25-150 mm |

| Strength | High tensile strength, stronger than flax | Strong but less than ramie |

| Moisture Absorption | Low absorption, quicker drying | Moderate absorption |

| Luster | Silky, shiny appearance | Matte to slight luster |

| Texture | Stiff, brittle without processing | Soft, flexible |

| Processing | Requires degumming to remove gums | Requires retting to separate fibers |

| Environmental Impact | Less water-intensive than flax | Higher water usage, more retting pollution |

| Common Uses | Textiles, industrial fabrics, upholstery | Textiles, linen, paper, composites |

Overview of Ramie Fiber and Flax Fiber

Ramie fiber, derived from the stalks of the Boehmeria plant, is known for its silky luster, high tensile strength, and resistance to bacterial attacks, making it ideal for textile blending and decorative fabrics. Flax fiber, sourced from the flax plant, is prized for its durability, moisture-wicking properties, and natural flaxen sheen, commonly used in linen production and eco-friendly textiles. Both fibers offer sustainable alternatives in the natural fiber market, with ramie providing higher gloss and flax delivering superior breathability.

Botanical Origins and Cultivation

Ramie fiber is derived from Boehmeria nivea, a flowering plant in the nettle family native to East Asia, while flax fiber comes from Linum usitatissimum, a member of the Linaceae family cultivated globally for its seeds and fibers. Ramie cultivation thrives in warm, humid climates with abundant rainfall, particularly in China and India, whereas flax prefers cooler, temperate regions such as Europe and Canada, requiring well-drained soils and moderate moisture. Both fibers undergo distinct harvesting processes: ramie is harvested by stripping bark from the stalk, and flax is pulled from the ground to preserve fiber length.

Physical and Mechanical Properties Comparison

Ramie fiber exhibits higher tensile strength and modulus compared to flax fiber, making it more suitable for applications requiring durability and stiffness. Flax fiber provides greater flexibility and elongation at break, enhancing comfort in textile products. Both fibers demonstrate excellent moisture absorption, but ramie has superior resistance to bacterial attack, contributing to its longevity in composite materials.

Sustainability and Environmental Impact

Ramie fiber, derived from the Boehmeria plant, requires minimal pesticides and grows rapidly, making it an eco-friendly alternative to flax fiber, which comes from the flax plant and demands more water and chemical treatments during cultivation. The processing of ramie involves fewer harmful chemicals and produces less waste compared to flax, contributing to reduced environmental pollution. Both fibers are biodegradable and renewable, but ramie's lower resource consumption and chemical use position it as a more sustainable choice in textile production.

Processing and Manufacturing Differences

Ramie fiber is derived from the stalks of the Boehmeria plant and requires chemical retting to remove gummy substances, whereas flax fiber is extracted through water retting, involving microbial action to break down pectins. Ramie's processing involves degumming processes using alkali treatment to separate the fiber, while flax fibers are separated by scutching and hackling to produce fine and strong fibers. Manufacturing flax fibers results in smoother, more lustrous textiles, whereas ramie fibers yield stiffer fabrics with higher moisture absorption but lower elasticity.

Applications in Textile and Industry

Ramie fiber, known for its high tensile strength and luster, is predominantly used in textiles for blending with cotton and wool to enhance fabric durability and appearance, making it ideal for upholstery and industrial sewing threads. Flax fiber, derived from the flax plant, is widely utilized in linen production and technical textiles, valued for its natural moisture-wicking properties and biodegradability, suitable for apparel, home furnishings, and composite materials in automotive industries. Both fibers support sustainable practices, with ramie offering superior resistance to microbial attack and flax providing excellent breathability in fabric applications.

Performance: Strength, Durability, and Comfort

Ramie fiber exhibits high tensile strength and excellent durability, making it resistant to wear and able to maintain shape over time, which is superior to many natural fibers. Flax fiber, known for its moderate strength and exceptional comfort, provides breathability and softness that enhances wearer comfort but may be less durable compared to ramie in heavy-duty applications. Both fibers offer unique performance traits, with ramie favoring longevity and resilience, while flax prioritizes comfort and moisture absorption.

Cost and Market Availability

Ramie fiber typically costs more than flax fiber due to its complex processing requirements and limited large-scale production. Flax fiber benefits from a well-established global market and widespread cultivation, making it more readily available and economically accessible for textile manufacturers. The cost-effectiveness and extensive supply chain of flax fiber contribute to its dominance in natural fiber markets compared to ramie.

Care, Maintenance, and Longevity

Ramie fiber requires gentle washing with mild detergents and should be air-dried to maintain its strength and luster, while flax fiber is more durable and can withstand machine washing on a gentle cycle but benefits from line drying to prevent shrinkage. Both fibers are prone to damage from prolonged exposure to sunlight, which can weaken their fibers and reduce longevity. Proper storage in a cool, dry place away from direct light enhances the lifespan of ramie and flax textiles, preserving their natural sheen and structural integrity.

Choosing Between Ramie and Flax Fibers

Ramie fiber offers exceptional strength and resistance to bacterial attack, making it ideal for durable textiles and upholstery, while flax fiber provides superior moisture absorption and breathability, favored in lightweight and comfortable fabrics like linen. Choosing between ramie and flax fibers depends on the desired fabric properties, with ramie excelling in durability and sheen, and flax prized for its softness and natural luster. Cost and environmental impact also influence the decision, as flax cultivation is generally more sustainable and widely accessible compared to the more labor-intensive processing of ramie.

Ramie Fiber vs Flax Fiber Infographic

materialdif.com

materialdif.com