Banana fiber is known for its high tensile strength and durability, making it ideal for producing textiles and ropes, while pineapple fiber offers a finer texture and is often used in delicate fabrics and handicrafts. Pineapple fiber, also called pina, has better moisture absorption and a softer feel compared to the coarser and stiffer banana fiber. Both fibers are sustainable alternatives to synthetic materials, each serving distinct purposes in eco-friendly fashion and interior design.

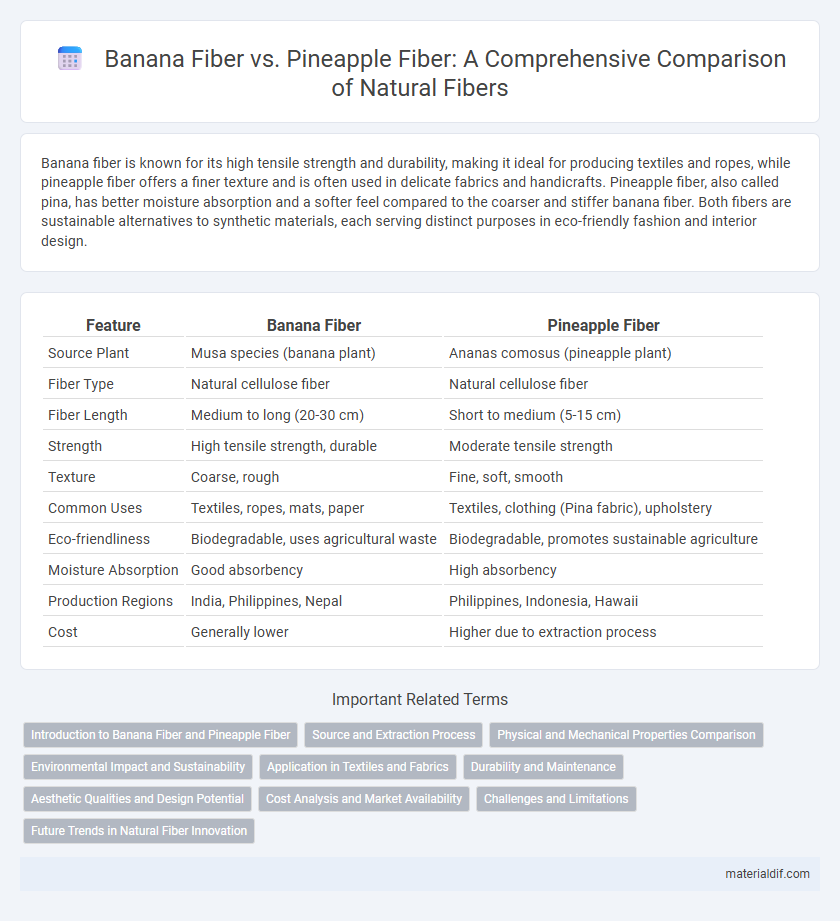

Table of Comparison

| Feature | Banana Fiber | Pineapple Fiber |

|---|---|---|

| Source Plant | Musa species (banana plant) | Ananas comosus (pineapple plant) |

| Fiber Type | Natural cellulose fiber | Natural cellulose fiber |

| Fiber Length | Medium to long (20-30 cm) | Short to medium (5-15 cm) |

| Strength | High tensile strength, durable | Moderate tensile strength |

| Texture | Coarse, rough | Fine, soft, smooth |

| Common Uses | Textiles, ropes, mats, paper | Textiles, clothing (Pina fabric), upholstery |

| Eco-friendliness | Biodegradable, uses agricultural waste | Biodegradable, promotes sustainable agriculture |

| Moisture Absorption | Good absorbency | High absorbency |

| Production Regions | India, Philippines, Nepal | Philippines, Indonesia, Hawaii |

| Cost | Generally lower | Higher due to extraction process |

Introduction to Banana Fiber and Pineapple Fiber

Banana fiber, derived from the pseudostem of the banana plant, is known for its strength, durability, and eco-friendly properties, making it a sustainable alternative for textiles and handicrafts. Pineapple fiber, extracted from pineapple leaf waste, offers a lightweight, soft texture and excellent breathability, often used in fashion and interior design for its natural sheen and biodegradability. Both fibers represent renewable resources with unique characteristics suited for sustainable material innovations.

Source and Extraction Process

Banana fiber is derived from the pseudostem of the banana plant, extracted through a process called retting, which involves soaking the stalks to separate the fibers, followed by manual scraping and washing. Pineapple fiber, known as pina fiber, is obtained from the leaf sheaths of the pineapple plant, extracted by decorticating the leaves to remove the outer layers and then scraping the fibers, typically using traditional methods combined with enzymatic treatments for enhanced softening. The differing botanical sources and extraction techniques result in unique fiber characteristics, with banana fiber being coarse and strong, while pineapple fiber is finer and more lustrous.

Physical and Mechanical Properties Comparison

Banana fiber exhibits higher tensile strength and greater elongation at break compared to pineapple fiber, making it more flexible and durable for textile applications. Pineapple fiber has a coarser texture with lower density but offers superior stiffness and resistance to wear, ideal for composite materials requiring rigidity. Both fibers show notable moisture absorption, yet banana fiber demonstrates better impact resistance due to its finer fiber diameter and higher lignin content.

Environmental Impact and Sustainability

Banana fiber, derived from banana plant pseudostems, offers a biodegradable and renewable alternative with low water and pesticide requirements, minimizing soil degradation and supporting sustainable agriculture. Pineapple fiber, extracted from pineapple leaf waste, utilizes agricultural byproducts, reducing waste and promoting circular economy practices while also requiring fewer chemical inputs compared to synthetic fibers. Both fibers contribute to reduced carbon footprints and enhanced eco-friendly textile production, yet pineapple fiber's use of agricultural residue may provide a slight advantage in minimizing resource consumption.

Application in Textiles and Fabrics

Banana fiber and pineapple fiber are both valued in textiles for their strength and eco-friendly properties, with banana fiber commonly used in making coarse fabrics, ropes, and paper products due to its durability and moisture resistance. Pineapple fiber, also known as pina, is prized in high-end fashion for its fine, lightweight texture ideal for delicate fabrics, traditional Filipino garments, and luxury textiles. Both fibers offer sustainable alternatives to synthetic materials, but pineapple fiber's finer quality makes it preferable for intricate, breathable fabrics, while banana fiber is favored for sturdy, long-lasting textiles.

Durability and Maintenance

Banana fiber exhibits superior durability compared to pineapple fiber due to its long, strong cellulose fibers, making it ideal for heavy-duty textiles and products. Pineapple fiber, while softer and more flexible, requires more careful maintenance to prevent fraying and wear over time. Both fibers benefit from proper cleaning, but banana fiber's resilience reduces the frequency of repairs and replacements in everyday use.

Aesthetic Qualities and Design Potential

Banana fiber offers a natural matte finish with a soft texture, making it ideal for rustic, eco-friendly designs that emphasize organic aesthetics. Pineapple fiber delivers a lustrous sheen and smooth surface, lending itself to sophisticated and elegant textile applications with high visual appeal. Both fibers provide versatile design potentials, but pineapple fiber's glossy appearance is favored in luxury fashion, while banana fiber suits artisanal and sustainable products.

Cost Analysis and Market Availability

Banana fiber offers a cost-effective alternative due to its abundant availability as agricultural waste, resulting in lower raw material expenses compared to pineapple fiber, which is derived from more limited pineapple leaf waste. Market availability favors banana fiber in regions with extensive banana cultivation, such as India and the Philippines, providing consistent supply chains, whereas pineapple fiber markets are more niche and concentrated in specific tropical areas. The cost differential and supply stability make banana fiber more attractive for large-scale textile and composite manufacturing applications.

Challenges and Limitations

Banana fiber faces challenges related to its coarse texture and limited tensile strength, which restrict its application in fine textiles and high-stress products. Pineapple fiber, while finer, encounters limitations due to its high production cost and the labor-intensive extraction process that affects scalability. Both fibers also struggle with inconsistent fiber quality caused by variations in cultivation conditions and processing techniques.

Future Trends in Natural Fiber Innovation

Banana fiber and pineapple fiber are gaining traction in sustainable textile markets due to their biodegradability and strength, with pineapple fiber showing rapid growth in fashion industries for its softness and sheen. Innovations are focusing on enhancing the mechanical properties and scalability of both fibers through bioengineering and eco-friendly extraction methods, targeting reduced environmental impact. Future trends emphasize blending these fibers with other natural materials to create hybrid textiles that meet performance demands while supporting circular economy goals.

Banana fiber vs Pineapple fiber Infographic

materialdif.com

materialdif.com