Aramid fiber offers exceptional impact resistance and flexibility, making it ideal for protective gear and ballistic applications. Carbon fiber provides superior stiffness, strength, and lightweight properties, preferred in aerospace, automotive, and high-performance sports equipment. Choosing between aramid and carbon fiber depends on the specific application requirements, balancing durability versus structural rigidity.

Table of Comparison

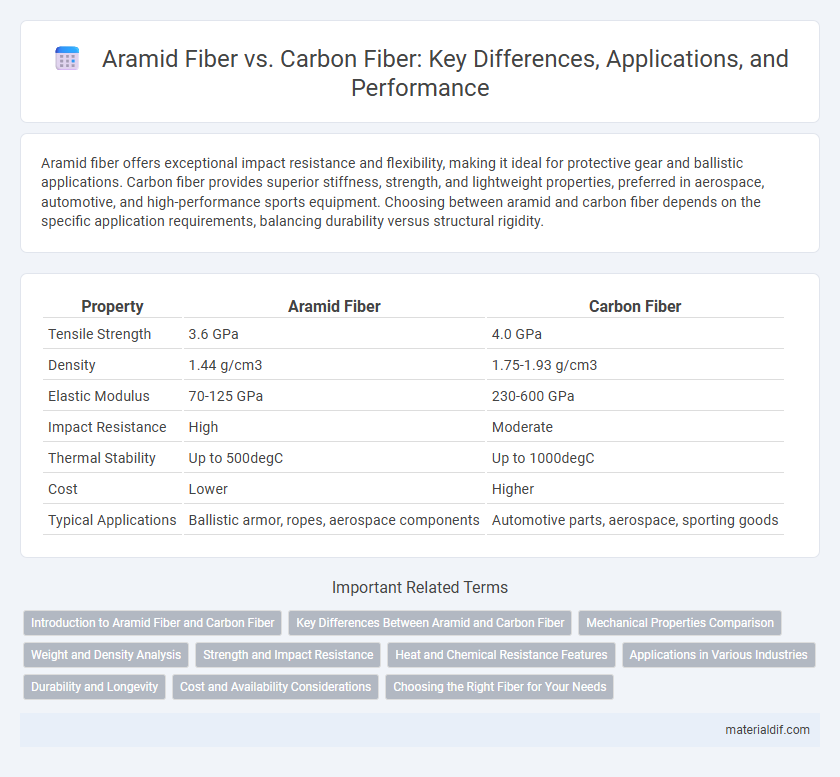

| Property | Aramid Fiber | Carbon Fiber |

|---|---|---|

| Tensile Strength | 3.6 GPa | 4.0 GPa |

| Density | 1.44 g/cm3 | 1.75-1.93 g/cm3 |

| Elastic Modulus | 70-125 GPa | 230-600 GPa |

| Impact Resistance | High | Moderate |

| Thermal Stability | Up to 500degC | Up to 1000degC |

| Cost | Lower | Higher |

| Typical Applications | Ballistic armor, ropes, aerospace components | Automotive parts, aerospace, sporting goods |

Introduction to Aramid Fiber and Carbon Fiber

Aramid fiber, known for its exceptional tensile strength and thermal stability, is widely used in aerospace, military, and automotive applications due to its lightweight yet durable nature. Carbon fiber offers superior stiffness, high tensile strength, and low weight, making it ideal for structural components in aerospace, automotive, and sporting goods industries. Both fibers enhance performance and durability, with aramid excelling in impact resistance and carbon fiber providing unmatched rigidity and strength-to-weight ratios.

Key Differences Between Aramid and Carbon Fiber

Aramid fiber offers exceptional impact resistance, high tensile strength, and superior flexibility, making it ideal for ballistic protection and flexible composites. Carbon fiber excels in rigidity, high stiffness-to-weight ratio, and superior fatigue resistance, preferred in aerospace and automotive structural applications. The primary differences lie in aramid fiber's toughness and energy absorption versus carbon fiber's stiffness and lightweight strength.

Mechanical Properties Comparison

Aramid fiber exhibits exceptional tensile strength and impact resistance, making it ideal for applications requiring high durability and flexibility. Carbon fiber offers superior stiffness and compressive strength, providing enhanced rigidity and lightweight performance in structural components. The choice between these fibers depends on the balance needed between flexibility and stiffness in mechanical design.

Weight and Density Analysis

Aramid fiber exhibits a lower density of approximately 1.44 g/cm3 compared to carbon fiber's density, which ranges from 1.75 to 1.93 g/cm3, making aramid fiber notably lighter in equal volumes. The reduced weight of aramid fiber enhances its suitability for applications demanding lightweight materials without sacrificing tensile strength, whereas carbon fiber's higher density contributes to superior stiffness and rigidity. Weight efficiency in composite structures often favors aramid fibers for impact resistance, while carbon fibers dominate in strength-to-weight ratio optimization due to their dense molecular structure.

Strength and Impact Resistance

Aramid fiber offers exceptional impact resistance and high tensile strength, making it ideal for applications requiring durability and flexibility, such as ballistic protection and aerospace components. Carbon fiber excels in tensile strength and stiffness, providing superior rigidity and strength-to-weight ratio, but it is more brittle and less impact-resistant compared to aramid fiber. Choosing between aramid and carbon fiber depends on the specific requirement for impact absorption versus maximum strength and stiffness in high-performance composite materials.

Heat and Chemical Resistance Features

Aramid fiber exhibits superior heat resistance, maintaining structural integrity at temperatures up to 500degC, making it ideal for high-temperature applications. Carbon fiber also offers excellent heat resistance but can degrade when exposed to certain chemicals, whereas aramid fiber provides enhanced chemical resistance against solvents and acids. These properties position aramid fiber as a preferred choice for environments requiring both thermal stability and chemical durability.

Applications in Various Industries

Aramid fiber offers exceptional impact resistance and flexibility, making it ideal for ballistic body armor, aerospace components, and automotive parts requiring high toughness. Carbon fiber boasts superior stiffness and strength-to-weight ratio, widely used in aerospace, automotive racing, sporting goods, and wind energy sectors. Industries select aramid fiber for protective gear and reinforcement, while carbon fiber dominates structural applications demanding lightweight durability and rigidity.

Durability and Longevity

Aramid fiber offers exceptional durability with high resistance to impact, abrasion, and heat, making it ideal for applications that require toughness and long-term wear resistance. Carbon fiber excels in longevity due to its superior stiffness and resistance to fatigue, maintaining structural integrity under repeated stress cycles over extended periods. Both fibers provide long-lasting performance, but aramid's impact resilience contrasts with carbon fiber's enduring mechanical properties in demanding environments.

Cost and Availability Considerations

Aramid fiber typically costs less than carbon fiber due to lower production expenses and more abundant raw materials, making it a cost-effective option for impact-resistant applications. Carbon fiber, although more expensive, offers superior strength-to-weight ratio and stiffness, but its higher price and more complex manufacturing process impact availability. Availability of aramid fiber is generally higher in commercial markets, while carbon fiber supply can be limited by production capacity and raw material constraints, influencing project budgets and timelines.

Choosing the Right Fiber for Your Needs

Aramid fiber offers exceptional impact resistance and flexibility, making it ideal for ballistic protection and flexible composite applications, whereas carbon fiber provides superior stiffness and tensile strength, suitable for aerospace and high-performance automotive parts. Selecting the right fiber depends on the specific performance criteria such as durability, weight, and cost-effectiveness required for the project. Evaluating factors like tensile modulus, elongation at break, and environmental resistance ensures optimal material choice tailored to your engineering or manufacturing needs.

Aramid Fiber vs Carbon Fiber Infographic

materialdif.com

materialdif.com