Ramie fiber boasts exceptional strength and durability, making it ideal for blended fabrics that require longevity, while linen fiber is renowned for its breathability and natural luster, perfect for lightweight, comfortable garments. Ramie retains shape well and resists bacteria, whereas linen offers excellent moisture-wicking properties and a soft texture that improves with washing. Both fibers are eco-friendly, but ramie requires more processing to achieve its silk-like finish compared to the more naturally textured linen.

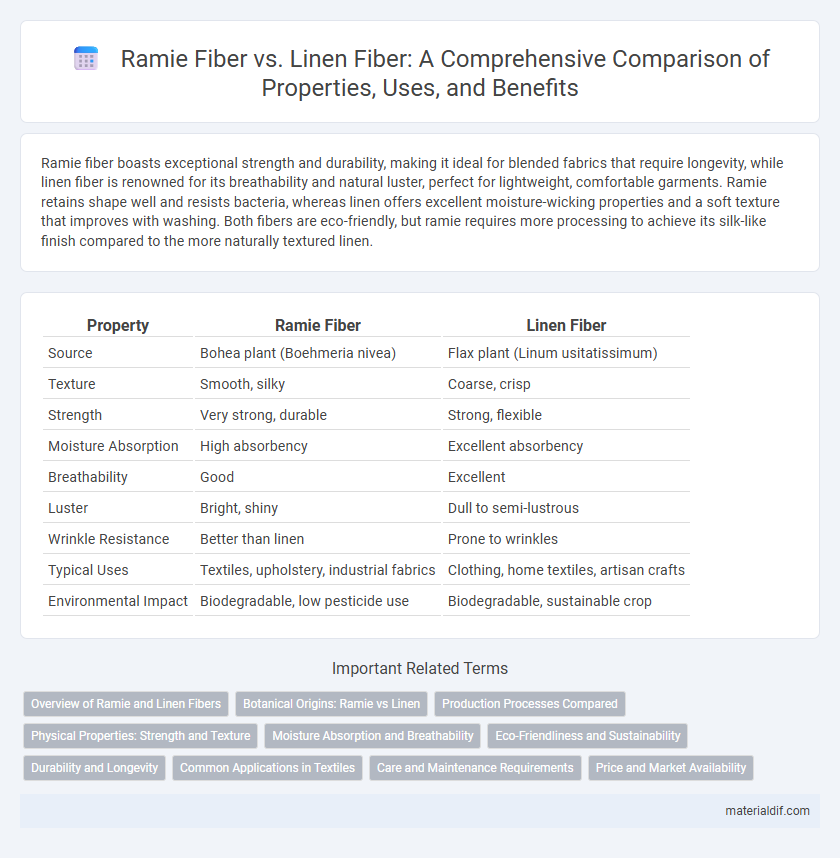

Table of Comparison

| Property | Ramie Fiber | Linen Fiber |

|---|---|---|

| Source | Bohea plant (Boehmeria nivea) | Flax plant (Linum usitatissimum) |

| Texture | Smooth, silky | Coarse, crisp |

| Strength | Very strong, durable | Strong, flexible |

| Moisture Absorption | High absorbency | Excellent absorbency |

| Breathability | Good | Excellent |

| Luster | Bright, shiny | Dull to semi-lustrous |

| Wrinkle Resistance | Better than linen | Prone to wrinkles |

| Typical Uses | Textiles, upholstery, industrial fabrics | Clothing, home textiles, artisan crafts |

| Environmental Impact | Biodegradable, low pesticide use | Biodegradable, sustainable crop |

Overview of Ramie and Linen Fibers

Ramie fiber, derived from the Boehmeria plant, is a durable natural fiber known for its silky luster and high moisture absorption, often used in textile blends to enhance strength and sheen. Linen fiber, sourced from the flax plant, is valued for its breathability, strength, and rough texture that softens with use, making it ideal for clothing and home textiles. Both fibers are biodegradable, sustainable options with distinct textures and properties that influence their applications in fashion and upholstery.

Botanical Origins: Ramie vs Linen

Ramie fiber originates from the stalks of the Boehmeria nivea plant, a flowering plant in the nettle family primarily grown in East Asia. Linen fiber is derived from the flax plant (Linum usitatissimum), cultivated mainly in Europe and parts of North America for its strong fibrous stalks. Both fibers share a bast fiber classification but differ botanically, with ramie sourced from a nettle relative and linen from flax, influencing their texture and durability in textile production.

Production Processes Compared

Ramie fiber production involves decorticating the stalks to separate the long, silky fibers, followed by degumming to remove pectin, resulting in a lustrous texture ideal for blending. Linen fiber is extracted from flax plants through retting, where microbial or chemical processes break down the pectins, then scutching and hackling are applied to obtain smooth fibers with high tensile strength. Ramie's labor-intensive degumming contrasts with linen's retting, affecting the environmental impact and overall fiber quality.

Physical Properties: Strength and Texture

Ramie fiber exhibits exceptional tensile strength, often surpassing linen fiber, making it highly durable for various textile applications. Its texture is coarse and stiff, giving fabrics a lustrous shine, whereas linen fiber has a softer, smoother texture with excellent moisture absorption properties. Both fibers are valued for their breathability, but ramie's rigidity contrasts with linen's flexible drape, influencing their specific uses in fabric blends.

Moisture Absorption and Breathability

Ramie fiber exhibits high moisture absorption, capable of absorbing up to 12-15% of its weight in water, which enhances its breathability and comfort in humid conditions. Linen fiber, derived from flax, typically absorbs around 12% moisture but is renowned for its superior breathability due to its natural weave structure that promotes air circulation. Both fibers provide excellent ventilation and moisture management, making them ideal for warm-weather textiles, though ramie's stronger absorbency slightly favors moisture retention.

Eco-Friendliness and Sustainability

Ramie fiber, derived from the stalks of the Chinese nettle plant, offers superior biodegradability and requires fewer pesticides compared to linen, which is obtained from flax plants. Linen fiber cultivation demands more water and intensive processing, whereas ramie's rapid growth and minimal agricultural inputs contribute to a lower environmental footprint. Both fibers are renewable, but ramie's enhanced sustainability profile makes it a more eco-friendly choice for sustainable textile production.

Durability and Longevity

Ramie fiber showcases superior durability due to its high tensile strength, making it resistant to wear and tear compared to linen fiber, which is more prone to weakening over time. Despite both fibers being natural and breathable, ramie offers enhanced longevity in textiles, retaining its shape and texture even after multiple washes. Linen fiber, while strong, tends to degrade faster in harsh environmental conditions, reducing its lifespan relative to ramie.

Common Applications in Textiles

Ramie fiber is commonly used in blending with cotton and wool to enhance fabric strength and luster, making it ideal for upholstery, wall coverings, and industrial sewing threads. Linen fiber, derived from the flax plant, is highly favored for apparel, home textiles such as tablecloths and bed linens, and lightweight summer clothing due to its breathable and moisture-wicking properties. Both fibers are valued in textile manufacturing for durability and comfort but serve distinct purposes based on their texture and finish.

Care and Maintenance Requirements

Ramie fiber requires gentle washing with mild detergents and should be air-dried to maintain its luster and prevent fiber weakening. Linen fiber is more durable and can withstand machine washing on a gentle cycle, but requires ironing while damp to reduce wrinkles. Both fibers benefit from avoiding high heat during drying to preserve fabric strength and texture.

Price and Market Availability

Ramie fiber typically commands a higher price than linen fiber due to its labor-intensive extraction process and limited large-scale production, resulting in less market availability. Linen fiber is more widely available and competitively priced, benefiting from established global cultivation and processing infrastructure. Both fibers are valued for their durability and breathability, but linen remains more accessible to manufacturers and consumers worldwide.

Ramie Fiber vs Linen Fiber Infographic

materialdif.com

materialdif.com