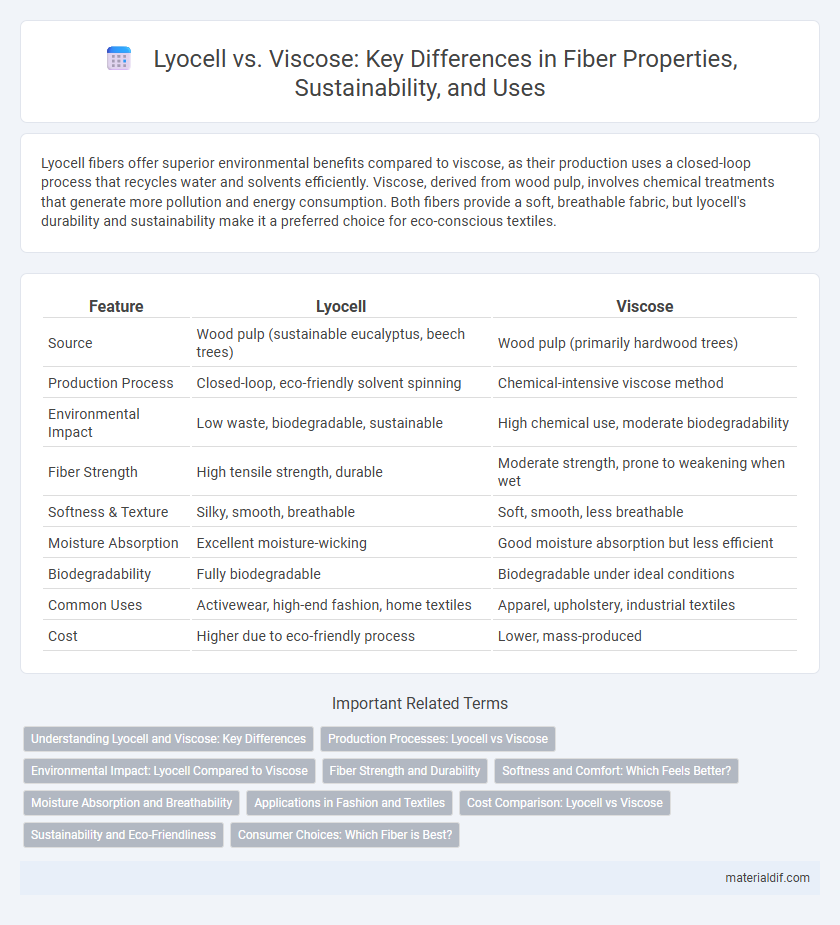

Lyocell fibers offer superior environmental benefits compared to viscose, as their production uses a closed-loop process that recycles water and solvents efficiently. Viscose, derived from wood pulp, involves chemical treatments that generate more pollution and energy consumption. Both fibers provide a soft, breathable fabric, but lyocell's durability and sustainability make it a preferred choice for eco-conscious textiles.

Table of Comparison

| Feature | Lyocell | Viscose |

|---|---|---|

| Source | Wood pulp (sustainable eucalyptus, beech trees) | Wood pulp (primarily hardwood trees) |

| Production Process | Closed-loop, eco-friendly solvent spinning | Chemical-intensive viscose method |

| Environmental Impact | Low waste, biodegradable, sustainable | High chemical use, moderate biodegradability |

| Fiber Strength | High tensile strength, durable | Moderate strength, prone to weakening when wet |

| Softness & Texture | Silky, smooth, breathable | Soft, smooth, less breathable |

| Moisture Absorption | Excellent moisture-wicking | Good moisture absorption but less efficient |

| Biodegradability | Fully biodegradable | Biodegradable under ideal conditions |

| Common Uses | Activewear, high-end fashion, home textiles | Apparel, upholstery, industrial textiles |

| Cost | Higher due to eco-friendly process | Lower, mass-produced |

Understanding Lyocell and Viscose: Key Differences

Lyocell is produced using a closed-loop process that recycles water and solvents, making it environmentally friendly, whereas viscose relies on chemically intensive methods with higher environmental impact. Lyocell fibers offer superior strength, moisture absorbency, and breathability compared to viscose, which tends to be less durable and more prone to wrinkles. Both fibers are derived from cellulose, but lyocell's production technology and fiber properties provide better sustainability and performance in textile applications.

Production Processes: Lyocell vs Viscose

Lyocell is produced through a closed-loop process using non-toxic solvents, which significantly reduces environmental impact and recycles nearly 99% of the chemicals used. In contrast, viscose production involves chemical-intensive steps using carbon disulfide and sulfuric acid, leading to higher pollution and waste generation. The sustainable manufacturing of lyocell offers a cleaner alternative to the traditional, more harmful viscose production process.

Environmental Impact: Lyocell Compared to Viscose

Lyocell production utilizes a closed-loop process that recycles water and solvents, significantly reducing environmental pollution compared to viscose manufacturing, which involves toxic chemicals like carbon disulfide and releases harmful effluents. Lyocell fibers are biodegradable and sourced from sustainably managed wood, minimizing deforestation and chemical use, whereas viscose often derives from less sustainable wood pulp and entails higher water consumption. The lower ecological footprint of lyocell makes it a more environmentally responsible option in textile fiber production.

Fiber Strength and Durability

Lyocell fibers exhibit superior strength and durability compared to viscose due to their closed-loop production process that retains cellulose integrity, resulting in higher tensile strength and resistance to wear. Viscose fibers tend to weaken when wet, leading to reduced durability and increased pilling over time. The enhanced mechanical properties of lyocell make it a preferred choice for applications requiring long-lasting, robust textiles.

Softness and Comfort: Which Feels Better?

Lyocell fibers are renowned for their exceptional softness and moisture-wicking properties, offering enhanced comfort compared to viscose, which tends to feel slightly heavier and less breathable. Lyocell's smooth surface reduces skin irritation, making it ideal for sensitive skin, while viscose, though soft, can lose shape and feel damp in humid conditions. Consumers seeking a breathable, luxurious fabric with superior softness often prefer lyocell over viscose for everyday wear and bedding.

Moisture Absorption and Breathability

Lyocell fibers exhibit superior moisture absorption and breathability compared to viscose, enabling enhanced comfort and dryness in textiles. The unique cellulose structure of lyocell allows it to absorb moisture up to 50% more efficiently while maintaining excellent air circulation. Viscose, although breathable, often retains more moisture against the skin, reducing overall fabric performance in humidity management.

Applications in Fashion and Textiles

Lyocell fibers, known for their durability and moisture-wicking properties, are widely used in high-performance activewear, sustainable fashion collections, and luxury textiles due to their eco-friendly production process and silky texture. Viscose, favored for its softness and drape, is commonly utilized in casual clothing, linings, and lightweight dresses but involves a chemically intensive manufacturing method. Both fibers offer versatility, yet Lyocell's biodegradability and strength position it prominently in eco-conscious apparel and textile innovations.

Cost Comparison: Lyocell vs Viscose

Lyocell production involves a more environmentally friendly and closed-loop process, but its manufacturing cost is generally higher compared to viscose due to advanced technology and sustainable raw material sourcing. Viscose fabric tends to be less expensive because it uses simpler, traditional chemical methods and readily available wood pulp, leading to lower production expenses. Prices for lyocell textiles often reflect premium market positioning, whereas viscose remains a cost-effective option for mass-produced fiber products.

Sustainability and Eco-Friendliness

Lyocell is more sustainable and eco-friendly than viscose due to its closed-loop production process that recycles water and solvents, minimizing environmental impact. Unlike viscose, which relies on harmful chemicals like sodium hydroxide and carbon disulfide, lyocell uses non-toxic solvents, reducing pollution and health risks. The biodegradability and renewable wood pulp source of lyocell further enhance its green credentials compared to the energy-intensive and chemically harsh viscose manufacturing methods.

Consumer Choices: Which Fiber is Best?

Lyocell offers superior sustainability and moisture-wicking properties compared to viscose, making it a preferred choice for environmentally conscious consumers seeking comfort and durability. Viscose, while softer and more affordable, involves chemical-intensive production that raises environmental concerns. Consumers prioritizing eco-friendly and long-lasting fibers often opt for lyocell due to its closed-loop manufacturing process and resilience.

Lyocell vs Viscose Infographic

materialdif.com

materialdif.com