Microfiber offers superior fineness and flexibility compared to macrofiber, allowing for enhanced softness and better moisture-wicking properties in textiles. Macrofiber, being thicker and more robust, provides increased durability and structural support in applications such as industrial reinforcements and heavy-duty fabrics. Choosing between microfiber and macrofiber depends on the specific performance requirements, balancing comfort and strength.

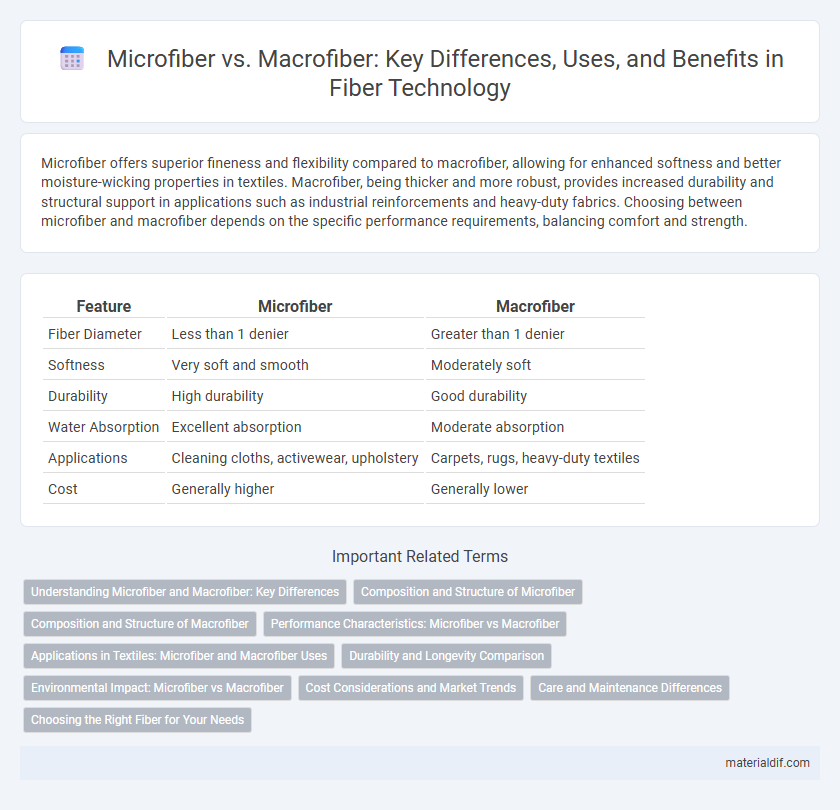

Table of Comparison

| Feature | Microfiber | Macrofiber |

|---|---|---|

| Fiber Diameter | Less than 1 denier | Greater than 1 denier |

| Softness | Very soft and smooth | Moderately soft |

| Durability | High durability | Good durability |

| Water Absorption | Excellent absorption | Moderate absorption |

| Applications | Cleaning cloths, activewear, upholstery | Carpets, rugs, heavy-duty textiles |

| Cost | Generally higher | Generally lower |

Understanding Microfiber and Macrofiber: Key Differences

Microfiber consists of extremely fine synthetic fibers, typically less than one denier in diameter, designed for high absorbency and softness, making it ideal for cleaning and textile applications. Macrofiber, much thicker and coarser, enhances structural reinforcement in concrete and composite materials due to its strength and durability. Understanding these key differences in fiber diameter and application helps optimize material selection for performance and cost-effectiveness in industrial and domestic uses.

Composition and Structure of Microfiber

Microfiber consists of ultra-fine synthetic fibers typically made from polyester, polyamide (nylon), or a blend, with diameters less than one denier, enabling a high surface area to volume ratio. The structure of microfiber features split fibers that create a dense network of filaments, enhancing absorption, softness, and filtration capacity compared to macrofibers, which are thicker and less flexible. This fine composition and intricate fiber arrangement contribute to microfiber's superior performance in cleaning, textile, and filtration applications.

Composition and Structure of Macrofiber

Macrofiber consists of larger diameter fibers typically made from synthetic materials like nylon, polyester, or polypropylene, providing enhanced strength and durability in construction applications. Its structure features a more robust, coarse texture with individual fibers bundled into thicker strands, allowing for superior crack resistance and load distribution in concrete reinforcement. Compared to microfiber, which has finer, smaller diameters designed for surface-level crack control, macrofibers deliver improved structural integrity due to their size and material composition.

Performance Characteristics: Microfiber vs Macrofiber

Microfiber offers superior performance characteristics such as enhanced flexibility, higher tensile strength, and finer texture that improves fabric softness and durability. Macrofiber provides better bulk and structural support, making it ideal for products requiring greater volume and resilience. The choice between microfiber and macrofiber depends on the desired balance of comfort, strength, and overall application needs.

Applications in Textiles: Microfiber and Macrofiber Uses

Microfiber, with its extremely fine synthetic fibers typically measuring less than 1 denier, is widely used in textile applications requiring softness, water resistance, and enhanced durability, such as activewear, upholstery, and cleaning cloths. Macrofiber, composed of thicker fibers often exceeding 1 denier, is preferred in textiles where strength, bulk, and insulation are crucial, including heavy-duty workwear, carpets, and outdoor gear. The difference in fiber diameter directly affects the performance characteristics, making microfibers ideal for moisture-wicking and lightweight fabrics, while macrofibers excel in abrasion resistance and structural support.

Durability and Longevity Comparison

Microfiber exhibits superior durability due to its finer synthetic fibers that resist wear and tear, making it ideal for high-traffic upholstery and clothing. Macrofiber, with its thicker strands, offers robust strength but tends to show signs of aging faster under frequent use or harsh conditions. Overall, microfiber's resilience and ability to maintain texture and color contribute to greater longevity compared to macrofiber in most applications.

Environmental Impact: Microfiber vs Macrofiber

Microfiber fabrics generate significant microplastic pollution during washing, releasing tiny fibers that contaminate waterways and harm aquatic life, while macrofiber materials, being thicker and less prone to shedding, contribute less to microplastic pollution. The production of microfibers often involves synthetic polymers like polyester and nylon, which are derived from non-renewable fossil fuels and require energy-intensive manufacturing processes. Using macrofiber alternatives made from natural or recycled materials can reduce the overall environmental footprint by minimizing microplastic emissions and reliance on virgin petrochemical resources.

Cost Considerations and Market Trends

Microfiber offers a cost-effective solution in textile manufacturing due to its lower raw material expenses and higher durability, making it popular in budget-conscious markets. Macrofiber, while generally more expensive because of higher production costs and premium material quality, is favored in industries prioritizing performance and longevity. Market trends indicate a growing demand for microfiber in fast fashion and home textiles, whereas macrofiber maintains steady growth in high-end apparel and technical fabrics.

Care and Maintenance Differences

Microfiber requires gentle washing with mild detergents and low-temperature water to maintain its softness and durability, avoiding bleach and fabric softeners that can degrade its fibers. Macrofiber, being coarser and more robust, tolerates higher washing temperatures and more aggressive detergents, making it easier to clean heavy soils but prone to faster wear if not properly maintained. Both fibers benefit from air drying or low heat drying to prevent fiber damage and ensure longevity.

Choosing the Right Fiber for Your Needs

Microfiber offers superior softness and finer texture, making it ideal for delicate fabrics and detailed cleaning tasks, while macrofiber provides greater durability and thicker strands suited for heavy-duty applications and prolonged wear. Selecting the right fiber depends on the intended use; microfiber excels in moisture-wicking and stain resistance for activewear and upholstery, whereas macrofiber is better for rugs and industrial textiles requiring robustness. Evaluating factors such as fabric feel, longevity, absorption, and maintenance will guide an informed choice between microfiber and macrofiber.

Microfiber vs Macrofiber Infographic

materialdif.com

materialdif.com