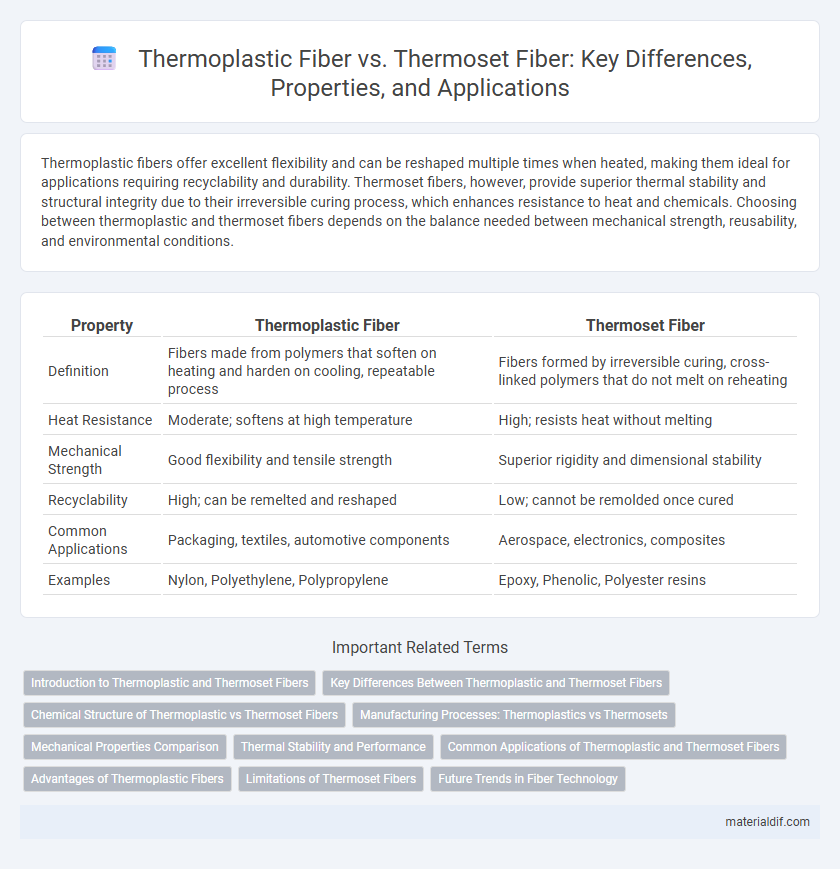

Thermoplastic fibers offer excellent flexibility and can be reshaped multiple times when heated, making them ideal for applications requiring recyclability and durability. Thermoset fibers, however, provide superior thermal stability and structural integrity due to their irreversible curing process, which enhances resistance to heat and chemicals. Choosing between thermoplastic and thermoset fibers depends on the balance needed between mechanical strength, reusability, and environmental conditions.

Table of Comparison

| Property | Thermoplastic Fiber | Thermoset Fiber |

|---|---|---|

| Definition | Fibers made from polymers that soften on heating and harden on cooling, repeatable process | Fibers formed by irreversible curing, cross-linked polymers that do not melt on reheating |

| Heat Resistance | Moderate; softens at high temperature | High; resists heat without melting |

| Mechanical Strength | Good flexibility and tensile strength | Superior rigidity and dimensional stability |

| Recyclability | High; can be remelted and reshaped | Low; cannot be remolded once cured |

| Common Applications | Packaging, textiles, automotive components | Aerospace, electronics, composites |

| Examples | Nylon, Polyethylene, Polypropylene | Epoxy, Phenolic, Polyester resins |

Introduction to Thermoplastic and Thermoset Fibers

Thermoplastic fibers are polymers that soften when heated and solidify upon cooling, allowing for easy reshaping and recycling, commonly used in applications requiring flexibility and durability. Thermoset fibers, by contrast, undergo irreversible chemical curing, resulting in a rigid, heat-resistant structure ideal for high-strength composites and structural components. Understanding the distinct thermal behavior and mechanical properties of thermoplastic and thermoset fibers is crucial for selecting materials tailored to specific industrial and engineering needs.

Key Differences Between Thermoplastic and Thermoset Fibers

Thermoplastic fibers soften when heated and can be remolded multiple times without altering their chemical structure, making them highly recyclable and suitable for applications requiring flexibility and reusability. Thermoset fibers, however, undergo a chemical curing process that creates a rigid, cross-linked structure, resulting in superior heat resistance, mechanical strength, and dimensional stability but preventing remelting or reshaping after curing. Key differences include thermoplastic fibers' ability to melt and reform versus thermoset fibers' permanent solid state, influencing their respective uses in industries like aerospace, automotive, and electronics.

Chemical Structure of Thermoplastic vs Thermoset Fibers

Thermoplastic fibers consist of linear or slightly branched polymer chains that allow them to be remelted and reshaped multiple times without significant chemical alteration. In contrast, thermoset fibers have heavily cross-linked polymer networks that create a rigid, infusible structure resistant to melting and deformation. This fundamental difference in chemical architecture influences thermal stability, mechanical properties, and recyclability in fiber applications.

Manufacturing Processes: Thermoplastics vs Thermosets

Thermoplastic fibers undergo manufacturing processes involving melting and reshaping, allowing for recycling and remolding without altering chemical properties, typically using extrusion or injection molding techniques. Thermoset fibers require curing through heat or chemical agents during production, creating irreversible cross-linked molecular structures that provide enhanced thermal stability and mechanical strength. The distinction in manufacturing processes results in thermoplastics offering greater flexibility and recyclability, while thermosets deliver superior durability and resistance to chemical and thermal degradation.

Mechanical Properties Comparison

Thermoplastic fibers exhibit high tensile strength and excellent impact resistance due to their molecular structure, which allows them to flex and return to shape under stress, making them ideal for applications requiring durability and flexibility. In contrast, thermoset fibers possess superior thermal stability and rigidity as their cross-linked polymer chains create a rigid network that resists deformation but are more brittle under mechanical load. The mechanical performance of thermoplastic fibers favors elongation and toughness, while thermoset fibers excel in hardness and structural integrity at elevated temperatures.

Thermal Stability and Performance

Thermoplastic fibers exhibit superior thermal stability due to their ability to soften and melt repeatedly without chemical degradation, making them suitable for applications requiring high thermal resistance and recyclability. In contrast, thermoset fibers undergo irreversible cross-linking during curing, providing excellent mechanical strength and dimensional stability at elevated temperatures but limited reusability. The choice between thermoplastic and thermoset fibers depends on the balance of thermal performance and end-use durability required in specific industrial or composite material applications.

Common Applications of Thermoplastic and Thermoset Fibers

Thermoplastic fibers are commonly used in applications requiring high impact resistance and recyclability, such as automotive parts, sports equipment, and packaging materials. Thermoset fibers find extensive use in aerospace, electronics, and construction industries due to their superior heat resistance, dimensional stability, and chemical resistance. Both fiber types contribute significantly to composite manufacturing, with thermoplastic fibers favored for their toughness and thermoset fibers prized for their rigidity and thermal stability.

Advantages of Thermoplastic Fibers

Thermoplastic fibers offer significant advantages such as superior recyclability and faster processing times compared to thermoset fibers, enabling efficient manufacturing cycles. These fibers exhibit excellent flexibility and impact resistance, making them ideal for applications requiring durability and deformation recovery. Their ability to be repeatedly melted and reshaped allows for cost-effective production and waste reduction in composite material industries.

Limitations of Thermoset Fibers

Thermoset fibers exhibit high thermal stability and chemical resistance but suffer from brittleness and low impact resistance, limiting their use in dynamic or flexible applications. Their infusible and insoluble nature makes recycling and reshaping difficult, resulting in environmental and manufacturing challenges. These limitations restrict thermoset fibers primarily to static structural components rather than applications requiring repeated stress or deformation.

Future Trends in Fiber Technology

Thermoplastic fibers, known for their recyclability and high melting points, are driving innovation in sustainable and lightweight materials, essential for future aerospace and automotive applications. Thermoset fibers, characterized by their superior heat resistance and structural stability, continue to dominate in high-performance composites but face challenges in recyclability and environmental impact. Advances in hybrid fiber technology and bio-based thermoplastics promise to bridge performance and sustainability gaps, shaping next-generation fiber materials for diverse industrial uses.

Thermoplastic Fiber vs Thermoset Fiber Infographic

materialdif.com

materialdif.com