Polyester fiber offers superior resistance to stretching and shrinking compared to polyamide fiber, making it ideal for durability in textiles. Polyamide fiber, commonly known as nylon, provides exceptional elasticity and abrasion resistance, enhancing comfort and wearability. Both fibers are widely used in apparel and industrial applications, but polyester excels in moisture resistance while polyamide is favored for its strength and lightweight properties.

Table of Comparison

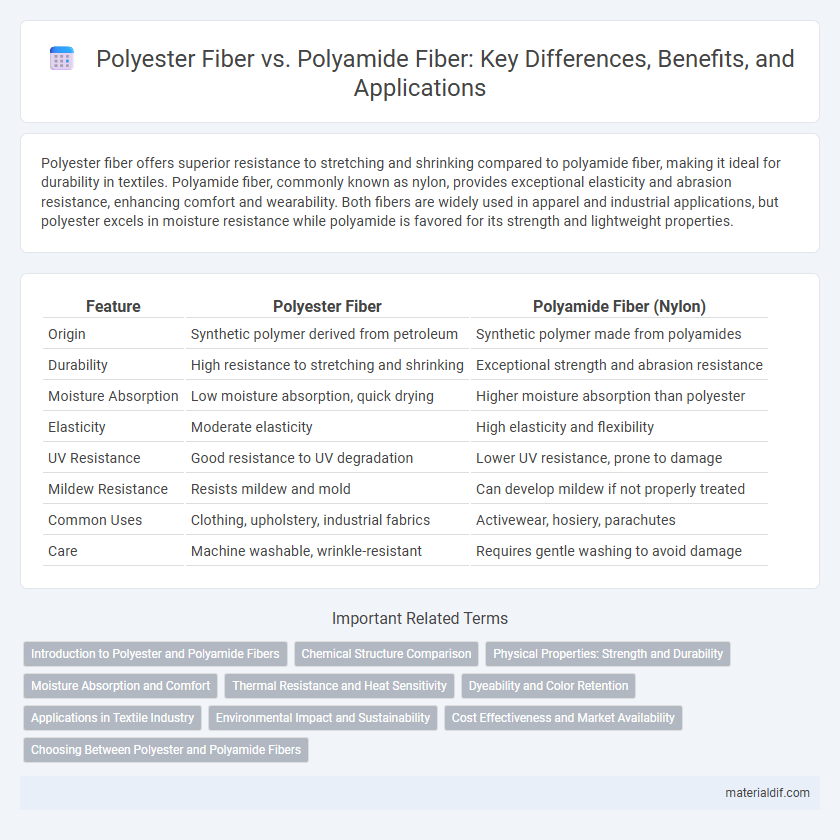

| Feature | Polyester Fiber | Polyamide Fiber (Nylon) |

|---|---|---|

| Origin | Synthetic polymer derived from petroleum | Synthetic polymer made from polyamides |

| Durability | High resistance to stretching and shrinking | Exceptional strength and abrasion resistance |

| Moisture Absorption | Low moisture absorption, quick drying | Higher moisture absorption than polyester |

| Elasticity | Moderate elasticity | High elasticity and flexibility |

| UV Resistance | Good resistance to UV degradation | Lower UV resistance, prone to damage |

| Mildew Resistance | Resists mildew and mold | Can develop mildew if not properly treated |

| Common Uses | Clothing, upholstery, industrial fabrics | Activewear, hosiery, parachutes |

| Care | Machine washable, wrinkle-resistant | Requires gentle washing to avoid damage |

Introduction to Polyester and Polyamide Fibers

Polyester fiber, derived from petroleum-based polymers, is known for its durability, wrinkle resistance, and hydrophobic properties, making it ideal for textiles and industrial applications. Polyamide fiber, commonly referred to as nylon, is characterized by high tensile strength, elasticity, and abrasion resistance, widely used in performance apparel and technical fabrics. Both fibers are synthetic, but polyester excels in moisture resistance while polyamide offers superior flexibility and resilience.

Chemical Structure Comparison

Polyester fibers are formed from polyethylene terephthalate (PET) with ester functional groups linking aromatic rings, providing high tensile strength and resistance to environmental degradation. Polyamide fibers, such as nylon, consist of repeating amide linkages between aliphatic chains, which create strong hydrogen bonds, enhancing flexibility and moisture absorption. The chemical difference in functional groups--esters in polyester versus amides in polyamide--leads to distinct properties influencing durability, elasticity, and hydrophilicity in textile applications.

Physical Properties: Strength and Durability

Polyester fiber exhibits high tensile strength and excellent resistance to abrasion, making it highly durable for long-term use in textiles. Polyamide fiber, commonly known as nylon, surpasses polyester in elasticity and impact resistance, providing superior toughness and flexibility. Both fibers resist wear and chemical damage, but polyamide's higher resilience makes it preferable for heavy-duty applications where strength retention under stress is critical.

Moisture Absorption and Comfort

Polyamide fiber, commonly known as nylon, exhibits higher moisture absorption compared to polyester fiber, allowing it to wick sweat away from the skin more effectively and enhance breathability. Polyester fiber's lower moisture absorption results in quicker drying times, making it ideal for activewear in humid conditions but potentially less comfortable in prolonged wear due to moisture retention near the skin. The superior moisture-wicking properties of polyamide contribute to increased comfort in performance textiles by maintaining dryness and reducing irritation during physical activities.

Thermal Resistance and Heat Sensitivity

Polyester fiber offers superior thermal resistance, maintaining structural integrity at temperatures up to 250degC, while polyamide fiber typically softens around 215degC, indicating higher heat sensitivity. This thermal stability makes polyester fiber ideal for applications requiring exposure to elevated temperatures or prolonged heat exposure. Due to its lower melting point, polyamide fiber is more prone to deformation and degradation under high-heat conditions, limiting its use in heat-intensive environments.

Dyeability and Color Retention

Polyester fiber exhibits excellent dyeability with disperse dyes, resulting in vibrant colors and high colorfastness under light and washing conditions. Polyamide fiber, known for its strong affinity to acid dyes, offers superior color retention and brightness, particularly in darker shades. Both fibers provide durable coloration, but polyamide typically delivers better dye penetration and longevity in high-moisture and abrasion-prone environments.

Applications in Textile Industry

Polyester fiber is widely used in textiles for its durability, resistance to shrinking and stretching, and moisture-wicking properties, making it ideal for sportswear, outdoor clothing, and home furnishings. Polyamide fiber, commonly known as nylon, excels in applications requiring high strength, elasticity, and abrasion resistance, such as activewear, hosiery, and industrial textiles. Both fibers contribute significantly to the textile industry by enhancing fabric performance and versatility across various end-use products.

Environmental Impact and Sustainability

Polyester fiber, derived from petroleum, has a higher carbon footprint and contributes more to microplastic pollution compared to polyamide fiber, which can be produced from both synthetic and bio-based sources. Polyamide fibers, especially those made from recycled materials like nylon, offer improved sustainability by reducing waste and energy consumption during production. Both fibers pose environmental challenges, but advancements in recycling technologies and bio-based alternatives are enhancing their sustainability profiles.

Cost Effectiveness and Market Availability

Polyester fiber offers superior cost-effectiveness due to its lower production expenses and widespread availability in the global market. Polyamide fiber, while generally more expensive, is prized for its enhanced durability and elasticity, limiting its use in budget-sensitive applications. Market availability of polyester fiber surpasses polyamide, driven by high demand in apparel, home textiles, and industrial sectors.

Choosing Between Polyester and Polyamide Fibers

Choosing between polyester and polyamide fibers depends on the desired durability and moisture management, as polyester offers excellent resistance to stretching, shrinking, and UV damage along with quick-drying properties. Polyamide fiber, known for its superior elasticity and abrasion resistance, provides enhanced comfort and flexibility, making it ideal for activewear and hosiery. Polyester excels in retaining color vibrancy and resisting chemical damage, while polyamide's lightweight and breathable nature suits applications requiring softness and moisture absorption.

Polyester Fiber vs Polyamide Fiber Infographic

materialdif.com

materialdif.com