Bamboo fiber is valued for its natural antibacterial properties and superior moisture-wicking ability, making it ideal for breathable, comfortable textiles. Ramie fiber stands out for its exceptional strength, durability, and resistance to wrinkles, often used in blended fabrics to enhance texture and longevity. Both fibers offer sustainable alternatives to traditional materials, with bamboo providing softness and ramie contributing robustness.

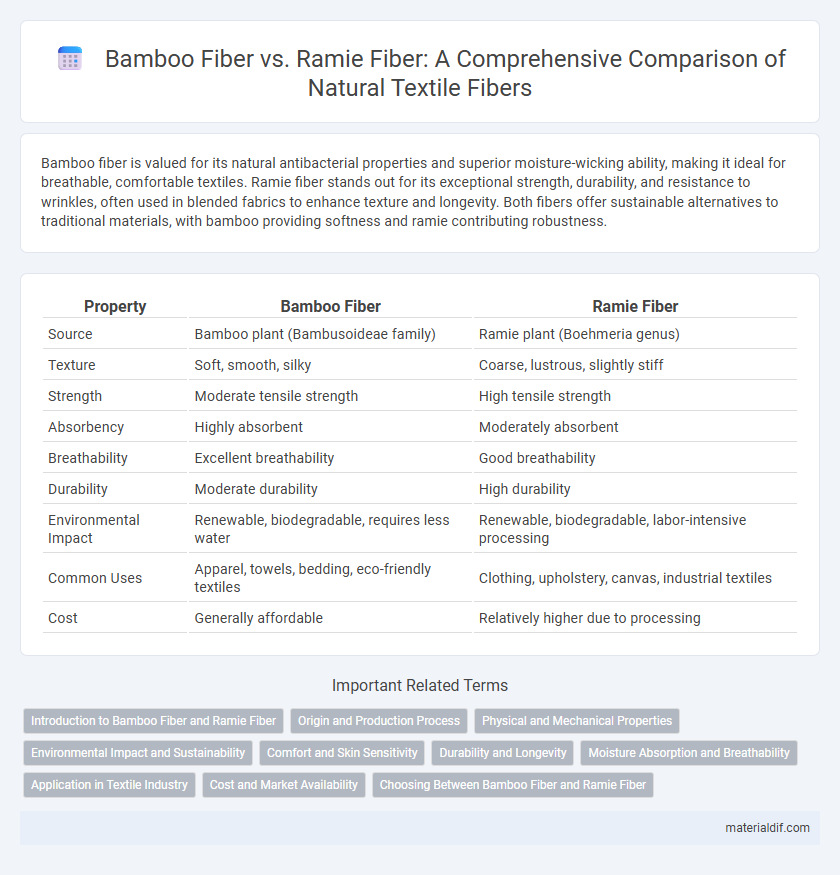

Table of Comparison

| Property | Bamboo Fiber | Ramie Fiber |

|---|---|---|

| Source | Bamboo plant (Bambusoideae family) | Ramie plant (Boehmeria genus) |

| Texture | Soft, smooth, silky | Coarse, lustrous, slightly stiff |

| Strength | Moderate tensile strength | High tensile strength |

| Absorbency | Highly absorbent | Moderately absorbent |

| Breathability | Excellent breathability | Good breathability |

| Durability | Moderate durability | High durability |

| Environmental Impact | Renewable, biodegradable, requires less water | Renewable, biodegradable, labor-intensive processing |

| Common Uses | Apparel, towels, bedding, eco-friendly textiles | Clothing, upholstery, canvas, industrial textiles |

| Cost | Generally affordable | Relatively higher due to processing |

Introduction to Bamboo Fiber and Ramie Fiber

Bamboo fiber, derived from the cellulose of bamboo plants, is renowned for its softness, breathability, and natural antibacterial properties, making it ideal for sustainable textiles and eco-friendly clothing. Ramie fiber, extracted from the stalks of the Chinese nettle plant, features exceptional strength, durability, and moisture-absorbing qualities commonly used in blends with cotton or linen to enhance fabric resilience. Both fibers represent renewable plant-based materials with unique benefits, contributing to environmentally conscious fabric production.

Origin and Production Process

Bamboo fiber originates from the bamboo plant, primarily found in Asia, where it undergoes a chemical or mechanical process to extract the cellulose for textile production. Ramie fiber comes from the stalks of the Ramie plant, a flowering plant in the nettle family, mainly cultivated in China and Brazil, and requires degumming to remove gums and pectins before spinning. The production of bamboo fiber involves either enzymatic treatment or chemical solvents, while ramie fiber production relies heavily on retting and degumming methods to ensure fiber softness and durability.

Physical and Mechanical Properties

Bamboo fiber exhibits high tensile strength and excellent moisture-wicking properties, making it suitable for breathable and durable textile applications. Ramie fiber is known for its exceptional tensile strength, resistance to wrinkling, and lustrous appearance, contributing to fabric durability and aesthetics. Both fibers demonstrate good mechanical stability, but bamboo fiber offers superior flexibility and softness compared to the coarser texture and higher stiffness of ramie fiber.

Environmental Impact and Sustainability

Bamboo fiber and ramie fiber both offer sustainable textile options with distinct environmental impacts. Bamboo fiber is highly renewable, grows quickly without pesticides, and requires minimal water, making it eco-friendly; however, its chemical-intensive processing can reduce sustainability. Ramie fiber, derived from a flowering plant, involves less processing with fewer chemicals, enhancing biodegradability and lower environmental harm, though it demands more water and labor during cultivation compared to bamboo.

Comfort and Skin Sensitivity

Bamboo fiber offers superior moisture-wicking properties and breathability, making it highly comfortable and ideal for sensitive skin due to its natural antibacterial qualities. Ramie fiber, while strong and durable, can be less soft and may cause irritation for individuals with delicate skin. Bamboo fiber's hypoallergenic nature supports comfort and reduces the risk of skin sensitivity more effectively than ramie.

Durability and Longevity

Bamboo fiber exhibits exceptional durability due to its strong cellulose structure and natural antibacterial properties, making it resistant to wear and tear while maintaining softness. Ramie fiber, known for its high tensile strength and resistance to stretching, offers impressive longevity, especially in mixed fabric blends where it enhances durability. Both fibers provide sustainable options, but bamboo's moisture-wicking and antimicrobial attributes contribute to maintaining fabric integrity over time.

Moisture Absorption and Breathability

Bamboo fiber exhibits superior moisture absorption compared to ramie fiber, with a moisture regain rate of approximately 11-12%, making it highly effective in wicking sweat away from the skin. Ramie fiber, while breathable due to its porous structure, has lower moisture absorption capacity around 7%, which can result in less effective sweat management. The breathability of bamboo fiber also contributes to enhanced comfort in hot and humid conditions, outperforming ramie fiber in promoting airflow and dryness.

Application in Textile Industry

Bamboo fiber and ramie fiber both serve distinct roles in the textile industry, with bamboo fiber prized for its softness, moisture-wicking properties, and antibacterial qualities making it ideal for activewear, bedding, and eco-friendly garments. Ramie fiber, known for its exceptional strength, durability, and lustrous appearance, is commonly used in blended fabrics for upholstery, industrial textiles, and formal wear, providing enhanced wrinkle resistance and texture. The choice between bamboo and ramie fibers depends on the specific application requirements such as comfort, strength, and environmental sustainability within textile manufacturing.

Cost and Market Availability

Bamboo fiber typically offers a lower cost due to abundant raw material supply and streamlined processing methods, making it widely accessible in global textile markets. Ramie fiber tends to be more expensive, reflecting its labor-intensive harvesting and limited cultivation regions, contributing to a niche market presence. Market availability favors bamboo fiber with extensive industrial-scale production, while ramie remains specialized, often reserved for high-end or eco-friendly textile applications.

Choosing Between Bamboo Fiber and Ramie Fiber

Bamboo fiber offers natural antibacterial properties, high moisture-wicking capabilities, and a soft texture ideal for breathable, eco-friendly textiles. Ramie fiber is valued for its strength, durability, and resistance to wrinkling, making it suitable for heavy-duty fabric blends and long-lasting garments. Choosing between bamboo and ramie fiber depends on prioritizing softness and antimicrobial benefits versus tensile strength and wrinkle resistance in sustainable fabric applications.

Bamboo Fiber vs Ramie Fiber Infographic

materialdif.com

materialdif.com