Glass fiber offers excellent tensile strength and cost-effectiveness, making it ideal for insulation and reinforcement applications. Ceramic fiber provides superior heat resistance and durability at high temperatures, suitable for industrial furnaces and kilns. Choosing between glass fiber and ceramic fiber depends on the required thermal performance and mechanical properties for specific applications.

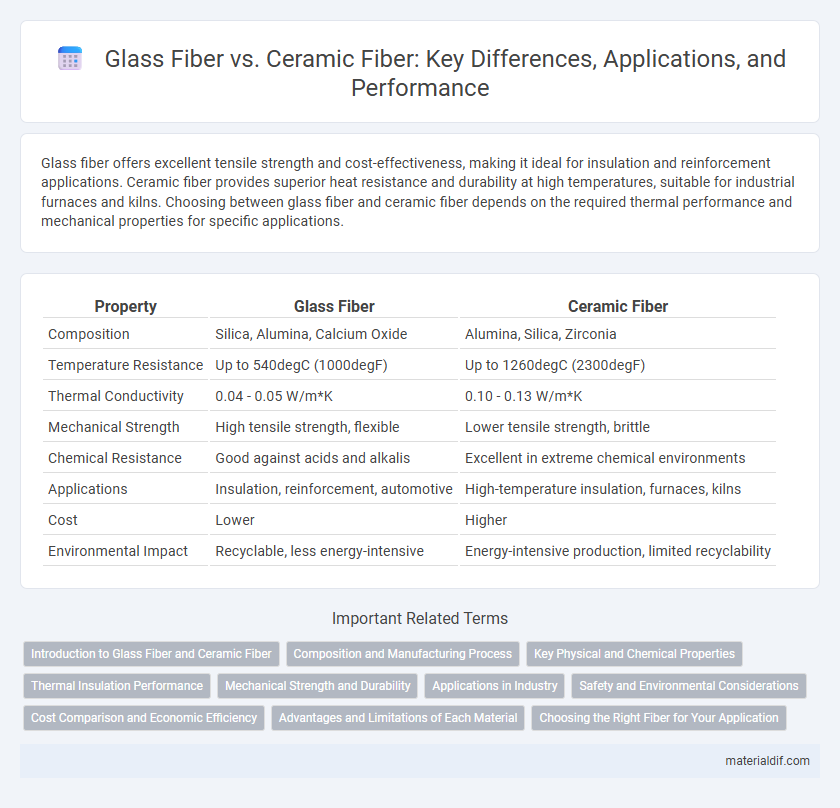

Table of Comparison

| Property | Glass Fiber | Ceramic Fiber |

|---|---|---|

| Composition | Silica, Alumina, Calcium Oxide | Alumina, Silica, Zirconia |

| Temperature Resistance | Up to 540degC (1000degF) | Up to 1260degC (2300degF) |

| Thermal Conductivity | 0.04 - 0.05 W/m*K | 0.10 - 0.13 W/m*K |

| Mechanical Strength | High tensile strength, flexible | Lower tensile strength, brittle |

| Chemical Resistance | Good against acids and alkalis | Excellent in extreme chemical environments |

| Applications | Insulation, reinforcement, automotive | High-temperature insulation, furnaces, kilns |

| Cost | Lower | Higher |

| Environmental Impact | Recyclable, less energy-intensive | Energy-intensive production, limited recyclability |

Introduction to Glass Fiber and Ceramic Fiber

Glass fiber, primarily composed of silica-based glass, offers high tensile strength, excellent thermal insulation, and resistance to moisture and chemicals, making it ideal for composites, insulation, and reinforcement applications. Ceramic fiber, made from alumina and silica, provides superior heat resistance, withstanding temperatures above 1,260degC (2,300degF), making it suitable for high-temperature insulation and refractory materials. Both fibers differ significantly in thermal properties and applications, with glass fiber excelling in structural support and ceramic fiber dominating in thermal protection.

Composition and Manufacturing Process

Glass fiber is primarily composed of silica (SiO2) along with other oxides such as alumina and calcium oxide, manufactured through melting raw materials and extruding them into thin strands. Ceramic fiber consists mainly of alumina and silica with varying ratios depending on the type, produced by spinning molten ceramic materials or by blowing techniques to create flexible, heat-resistant fibers. The glass fiber manufacturing process emphasizes uniformity and strength for applications like reinforcement, while ceramic fibers focus on high-temperature insulation and thermal stability.

Key Physical and Chemical Properties

Glass fiber exhibits superior tensile strength and excellent thermal stability up to 600degC, making it ideal for insulation and reinforcement applications. Ceramic fiber, with a higher melting point exceeding 1400degC, offers exceptional resistance to chemical corrosion and thermal shock, suited for high-temperature industrial environments. Both fibers differ in chemical composition: glass fiber primarily consists of silica and alumina, while ceramic fiber includes refractory oxides such as alumina and silica, defining their distinct performance profiles.

Thermal Insulation Performance

Glass fiber offers excellent thermal insulation with a typical operating temperature range up to 550degC, making it suitable for general industrial applications. Ceramic fiber withstands much higher temperatures, up to 1400degC or more, providing superior heat resistance and low thermal conductivity in extreme environments. The choice between glass fiber and ceramic fiber depends on required maximum temperature and thermal insulation efficiency for specific high-temperature applications.

Mechanical Strength and Durability

Glass fiber exhibits higher mechanical strength and excellent tensile properties, making it suitable for applications requiring robust structural support. Ceramic fiber offers superior durability in high-temperature environments and resistance to chemical corrosion, enhancing longevity under extreme conditions. Choosing between glass and ceramic fiber depends on the balance between mechanical performance and thermal-chemical resistance needed for specific industrial uses.

Applications in Industry

Glass fiber is extensively used in automotive, construction, and aerospace industries for insulation, reinforcement, and thermal protection due to its high tensile strength and corrosion resistance. Ceramic fiber is preferred in high-temperature applications like furnaces, kilns, and boilers, offering superior thermal insulation and resistance to chemical degradation in environments exceeding 1000degC. Both materials play critical roles in enhancing energy efficiency and durability in industrial processes, with glass fiber excelling in electrical insulation and ceramic fiber specializing in extreme heat resistance.

Safety and Environmental Considerations

Glass fiber is made from silica-based glass and is generally considered safe for industrial use when proper protective measures are in place, though inhalation of fine glass fibers can pose respiratory risks. Ceramic fiber, composed of alumina and silica, offers excellent heat resistance but may release respirable fibers that are potentially carcinogenic, requiring stringent handling protocols and protective equipment. Environmentally, glass fiber production has a lower energy footprint compared to ceramic fiber, while disposal of ceramic fiber demands careful management due to its persistent and non-biodegradable nature.

Cost Comparison and Economic Efficiency

Glass fiber offers a lower initial cost compared to ceramic fiber, making it a more budget-friendly option for large-scale insulation projects. Ceramic fiber, despite its higher price, provides superior thermal resistance and longer lifespan, resulting in greater economic efficiency through reduced maintenance and replacement expenses. The choice between the two depends on balancing upfront investment against long-term savings, with ceramic fiber being more cost-effective in high-temperature or demanding industrial applications.

Advantages and Limitations of Each Material

Glass fiber offers superior tensile strength and excellent resistance to moisture, making it ideal for reinforcement in composite materials and insulation in humid environments. Ceramic fiber withstands extremely high temperatures and provides exceptional thermal insulation, which is beneficial for furnace linings and industrial applications involving intense heat. Limitations include glass fiber's susceptibility to damage from alkaline environments and ceramic fiber's brittleness and higher cost compared to glass fiber.

Choosing the Right Fiber for Your Application

Glass fiber offers excellent tensile strength, flexibility, and cost-effectiveness, making it ideal for applications requiring lightweight reinforcement and thermal insulation up to 650degC. Ceramic fiber withstands extreme temperatures above 1,260degC with superior chemical and thermal stability, suited for industrial furnaces, kilns, and high-temperature insulation. Selecting the right fiber depends on temperature resistance, mechanical strength, chemical exposure, and budget constraints specific to the application environment.

Glass Fiber vs Ceramic Fiber Infographic

materialdif.com

materialdif.com