Fiber matting creates a non-woven structure by entangling fibers into a dense, uniform sheet, offering excellent filtration and cushioning properties. Fiber weaving interlaces fibers in a systematic pattern, producing a strong, flexible fabric ideal for textiles and composite materials. Choosing between fiber matting and fiber weaving depends on the desired strength, texture, and functional application of the fiber product.

Table of Comparison

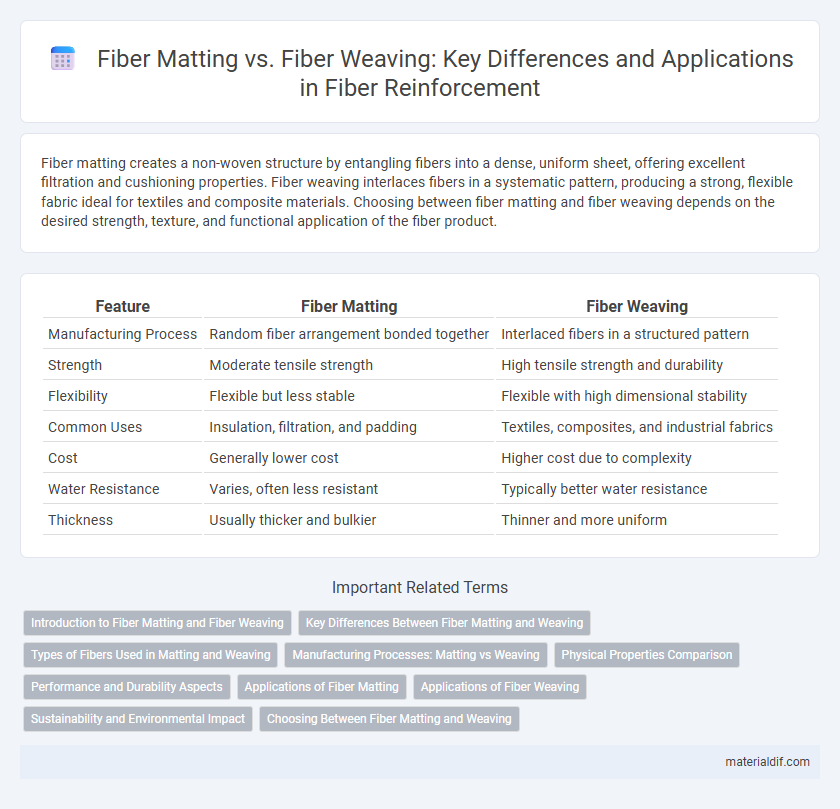

| Feature | Fiber Matting | Fiber Weaving |

|---|---|---|

| Manufacturing Process | Random fiber arrangement bonded together | Interlaced fibers in a structured pattern |

| Strength | Moderate tensile strength | High tensile strength and durability |

| Flexibility | Flexible but less stable | Flexible with high dimensional stability |

| Common Uses | Insulation, filtration, and padding | Textiles, composites, and industrial fabrics |

| Cost | Generally lower cost | Higher cost due to complexity |

| Water Resistance | Varies, often less resistant | Typically better water resistance |

| Thickness | Usually thicker and bulkier | Thinner and more uniform |

Introduction to Fiber Matting and Fiber Weaving

Fiber matting involves bonding fibers randomly to create a dense, nonwoven fabric with high tensile strength and excellent moisture absorption properties, commonly used in filtration and insulation. Fiber weaving interlaces two sets of yarns at right angles, producing a woven fabric characterized by durability, flexibility, and intricate patterns, frequently applied in textiles and industrial applications. Understanding the structural differences between fiber matting and fiber weaving is crucial for selecting appropriate materials based on performance requirements and end-use scenarios.

Key Differences Between Fiber Matting and Weaving

Fiber matting involves bonding fibers randomly to create a non-woven structure, resulting in a dense, porous material ideal for filtration or insulation. Fiber weaving interlaces yarns in a systematic pattern, producing strong, flexible fabrics commonly used in textiles and composites. The key differences lie in structural organization, mechanical strength, and typical applications.

Types of Fibers Used in Matting and Weaving

Fiber matting primarily utilizes short-staple fibers such as cotton, jute, and coir, which bond together through entanglement processes to form dense, non-woven mats. In contrast, fiber weaving employs long-staple, continuous fibers like silk, wool, and flax, interlaced in warp and weft configurations to create structured fabric patterns. The inherent differences in fiber length and tensile properties dictate the suitability of specific fibers for matting's bonded texture versus weaving's interlaced fabric construction.

Manufacturing Processes: Matting vs Weaving

Fiber matting involves the entanglement of fibers into a non-woven sheet using mechanical, chemical, or thermal methods, creating a dense, uniform structure ideal for insulation and filtration. Fiber weaving interlaces warp and weft yarns perpendicularly, producing a fabric with higher tensile strength and flexibility, commonly used in textiles and composites. Manufacturing processes in matting emphasize random fiber orientation and bonding, while weaving requires precise yarn alignment and tension control for patterned fabric production.

Physical Properties Comparison

Fiber matting exhibits a random orientation of fibers, resulting in isotropic physical properties such as uniform strength and stiffness in all directions, while fiber weaving features interlaced fibers that provide anisotropic characteristics with enhanced tensile strength along warp and weft directions. Matting offers superior thickness and cushioning due to its loose fiber arrangement, whereas weaving delivers higher durability and abrasion resistance attributed to tightly woven patterns. The physical properties of fiber matting are ideal for filtration and insulation applications, whereas fiber weaving is preferable for structural and load-bearing components.

Performance and Durability Aspects

Fiber matting offers superior durability due to its random orientation of fibers, which enhances resistance to tearing and abrasion under high-stress conditions. On the other hand, fiber weaving provides optimized performance in tensile strength and flexibility thanks to its structured, interlaced fiber patterns. Both methods improve fiber performance, but woven fibers excel in uniform load distribution, while matting delivers enhanced impact resistance and longevity in harsh environments.

Applications of Fiber Matting

Fiber matting finds extensive applications in insulation and filtration industries due to its random fiber arrangement, which enhances thermal resistance and particle capture efficiency. It is widely used in automotive soundproofing, HVAC filters, and roofing materials, where durability and porous structure are critical. Compared to fiber weaving, matting offers superior flexural strength and moisture resistance, making it ideal for composite reinforcement and protective clothing.

Applications of Fiber Weaving

Fiber weaving is extensively utilized in industries such as aerospace, automotive, and construction due to its high strength-to-weight ratio and flexibility in design. The interlaced fiber structure improves mechanical properties, making woven fabrics ideal for producing composite materials and protective gear. Textile manufacturing also relies on fiber weaving for creating durable, breathable fabrics used in clothing and industrial filters.

Sustainability and Environmental Impact

Fiber matting utilizes short, randomly arranged fibers bonded together, which typically requires less energy and fewer chemicals compared to fiber weaving that interlaces longer fibers into fabrics. The production of fiber matting often results in lower carbon emissions and waste generation, enhancing its sustainability profile in industries like construction and automotive. Fiber weaving, while durable and reusable, involves more intensive processing stages that can increase environmental impact through higher water and chemical usage.

Choosing Between Fiber Matting and Weaving

Fiber matting offers enhanced insulation and soundproofing due to its dense, random fiber arrangement, making it ideal for thermal and acoustic applications. In contrast, fiber weaving provides superior tensile strength and flexibility, suitable for structural uses and textiles requiring durability and stretch. Selecting between fiber matting and weaving depends on the specific performance criteria such as insulation, strength, and application environment.

Fiber Matting vs Fiber Weaving Infographic

materialdif.com

materialdif.com