Open-end fiber spinning offers higher production speed and cost efficiency compared to ring spinning, making it ideal for mass-produced, coarse yarns. Ring spinning produces finer, stronger, and more uniform yarns, preferred for high-quality textile applications. The choice between the two methods depends on the desired yarn characteristics and end-use requirements.

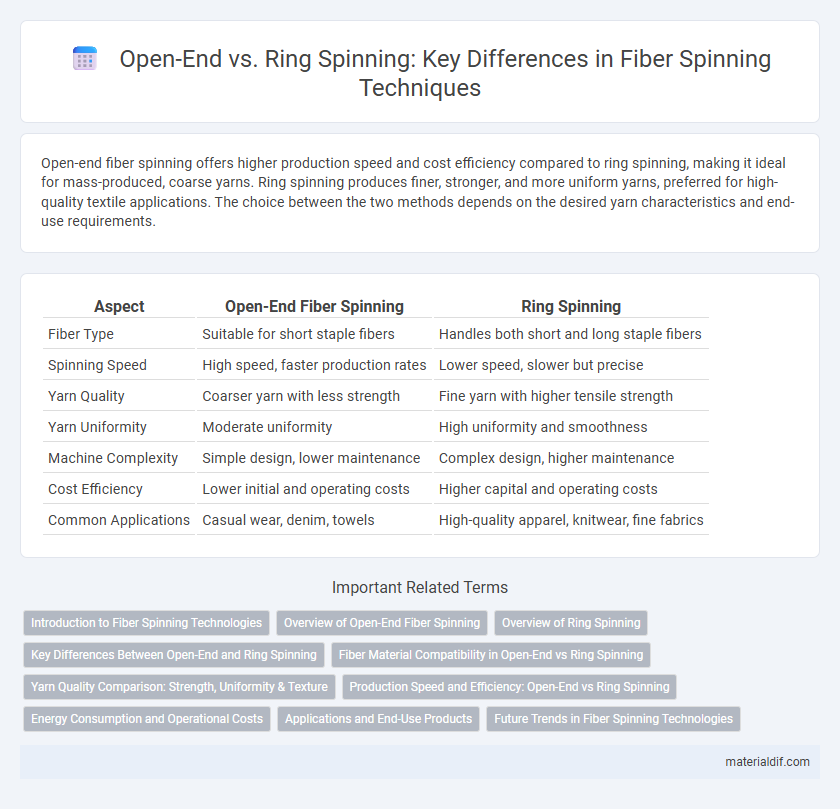

Table of Comparison

| Aspect | Open-End Fiber Spinning | Ring Spinning |

|---|---|---|

| Fiber Type | Suitable for short staple fibers | Handles both short and long staple fibers |

| Spinning Speed | High speed, faster production rates | Lower speed, slower but precise |

| Yarn Quality | Coarser yarn with less strength | Fine yarn with higher tensile strength |

| Yarn Uniformity | Moderate uniformity | High uniformity and smoothness |

| Machine Complexity | Simple design, lower maintenance | Complex design, higher maintenance |

| Cost Efficiency | Lower initial and operating costs | Higher capital and operating costs |

| Common Applications | Casual wear, denim, towels | High-quality apparel, knitwear, fine fabrics |

Introduction to Fiber Spinning Technologies

Open-End Fiber Spinning and Ring Spinning represent two primary technologies in the production of yarn from fibers, each with distinct mechanisms and applications. Open-End Spinning employs a rotor to draft and spin fibers directly from the sliver, enabling high-speed production and lower labor costs, while Ring Spinning uses a traditional spindle and ring system for producing stronger, finer yarns with superior uniformity. Understanding these fiber spinning technologies is essential for optimizing textile manufacturing processes based on fiber type, desired yarn properties, and production efficiency.

Overview of Open-End Fiber Spinning

Open-end fiber spinning is a high-speed yarn production technique that eliminates the need for a spindle, allowing fibers to be fed into a rotor where they are twisted mechanically to form yarn. This process significantly increases productivity and reduces labor costs compared to traditional ring spinning, producing coarser yarns suitable for denim and upholstery fabrics. Open-end spinning offers advantages such as uniform yarn quality, reduced hairiness, and better control over fiber orientation, making it ideal for mass textile manufacturing.

Overview of Ring Spinning

Ring spinning remains the most prevalent spinning method due to its ability to produce fine, strong, and high-quality yarn suitable for a wide range of textile applications. This process involves drawing and twisting fibers around a spindle within a rotating ring, resulting in yarns with superior tensile strength and uniformity. Compared to open-end spinning, ring spinning offers greater control over fiber alignment, making it ideal for premium fabrics requiring durability and smoothness.

Key Differences Between Open-End and Ring Spinning

Open-end fiber spinning produces yarn by feeding fibers into a rotor, enabling high-speed, cost-effective production with coarser yarn suited for denim and towels, while ring spinning twists fibers using a spindle for finer, stronger, and smoother yarn ideal for high-quality textiles. Open-end spinning offers faster output and lower labor costs but yields yarn with lower tensile strength and uniformity compared to ring spinning. Ring spinning, although slower and more expensive, is preferred for applications demanding durability and premium fabric texture.

Fiber Material Compatibility in Open-End vs Ring Spinning

Open-end fiber spinning accommodates a wider range of fiber lengths and lower-quality fibers due to its high-speed, rotor-based technology, making it ideal for coarse and shorter fibers like cotton blends and synthetic fibers. Ring spinning requires longer, finer fibers, such as long-staple cotton or wool, to produce stronger, smoother yarns with better tensile strength and uniformity. Fiber material compatibility in open-end spinning favors versatility and efficiency, whereas ring spinning prioritizes fiber quality for premium yarn production.

Yarn Quality Comparison: Strength, Uniformity & Texture

Open-end fiber spinning produces yarn with lower strength and less uniformity compared to ring spinning, which delivers superior tensile strength and consistent fiber alignment. The texture of open-end yarn tends to be coarser and bulkier, making it suitable for heavier fabrics, while ring-spun yarn is finer and smoother, ideal for high-quality textiles. Yarn strength ranges typically show ring-spun yarn exceeding open-end by up to 30%, emphasizing ring spinning's advantage in durability and fabric performance.

Production Speed and Efficiency: Open-End vs Ring Spinning

Open-end fiber spinning achieves higher production speeds, reaching up to 250 meters per minute, compared to ring spinning's typical 15-20 meters per minute. This increased speed translates to enhanced efficiency and reduced labor costs in mass textile manufacturing. Although open-end spinning offers faster output, ring spinning maintains superior yarn strength and quality, making it suitable for premium fabric production.

Energy Consumption and Operational Costs

Open-end fiber spinning consumes significantly less energy compared to ring spinning due to its simpler mechanical process and higher production speed, resulting in reduced operational costs. Ring spinning, while offering superior yarn quality and strength, requires more power-intensive machinery, increasing energy consumption and labor expenses. Choosing open-end spinning can optimize cost efficiency in large-scale production environments where energy savings are critical.

Applications and End-Use Products

Open-end fiber spinning is ideal for producing bulkier, coarser yarns used in denim, home textiles, and upholstery due to its high production speed and cost efficiency. Ring spinning yields finer, stronger yarns suitable for premium apparel, hosiery, and high-quality knitting fabrics that demand superior strength and smoothness. Both technologies are chosen based on the specific end-use requirements, with open-end favored for mass-produced, durable textiles and ring spinning preferred for fine, soft, and high-strength garments.

Future Trends in Fiber Spinning Technologies

Open-end fiber spinning technology is advancing with innovations in rotor design and automation, improving production speed and energy efficiency compared to traditional ring spinning. Ring spinning maintains superior fiber strength and yarn quality, but integration with smart sensors and AI-driven process controls promises enhanced precision and reduced waste in the future. Emerging hybrid systems combining open-end and ring spinning benefits are expected to reshape fiber manufacturing by balancing cost-effectiveness and high-quality output.

Open-End Fiber Spinning vs Ring Spinning Infographic

materialdif.com

materialdif.com