Continuous fibers provide superior mechanical strength and enhanced load transfer due to their unbroken length, making them ideal for high-performance composite materials. Discontinuous fibers, while easier to process and more cost-effective, offer reduced strength and stiffness because of the fiber length limitations and increased fiber-matrix interface areas. Selecting between continuous and discontinuous fibers depends on the specific application requirements, balancing performance needs with manufacturing constraints.

Table of Comparison

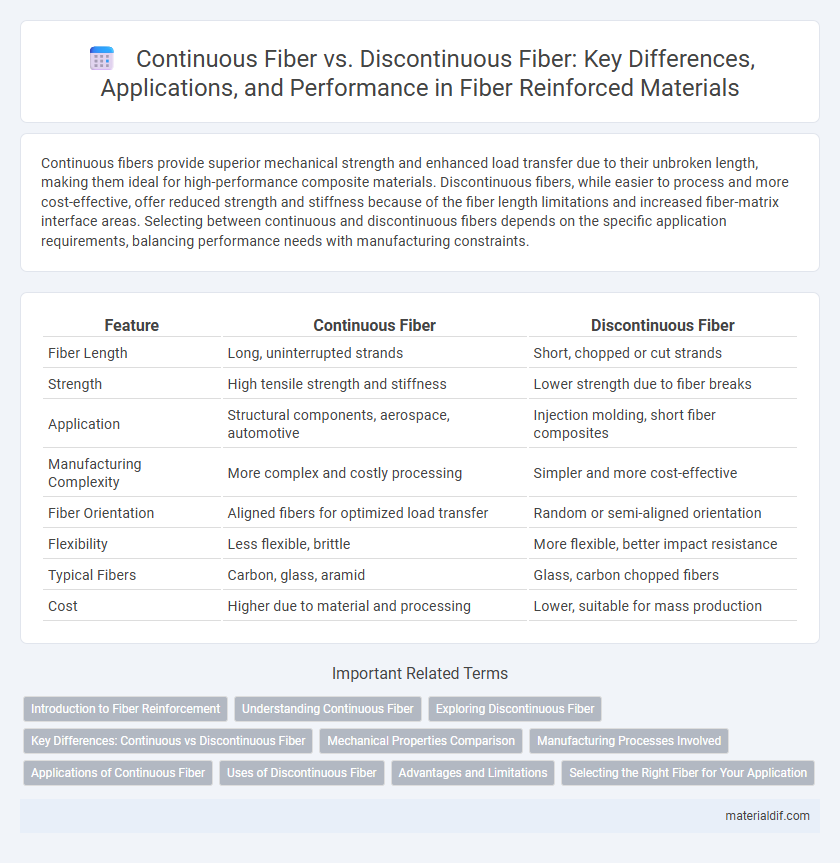

| Feature | Continuous Fiber | Discontinuous Fiber |

|---|---|---|

| Fiber Length | Long, uninterrupted strands | Short, chopped or cut strands |

| Strength | High tensile strength and stiffness | Lower strength due to fiber breaks |

| Application | Structural components, aerospace, automotive | Injection molding, short fiber composites |

| Manufacturing Complexity | More complex and costly processing | Simpler and more cost-effective |

| Fiber Orientation | Aligned fibers for optimized load transfer | Random or semi-aligned orientation |

| Flexibility | Less flexible, brittle | More flexible, better impact resistance |

| Typical Fibers | Carbon, glass, aramid | Glass, carbon chopped fibers |

| Cost | Higher due to material and processing | Lower, suitable for mass production |

Introduction to Fiber Reinforcement

Continuous fiber reinforcement provides superior mechanical strength and stiffness due to unbroken fiber lengths that enable efficient load transfer within composite materials. Discontinuous fiber reinforcement features shorter fiber segments, offering improved isotropy and easier fabrication but generally reduced tensile properties compared to continuous fibers. The choice between continuous and discontinuous fibers depends on application requirements, balancing performance, manufacturability, and cost in fiber-reinforced polymer composites.

Understanding Continuous Fiber

Continuous fiber consists of long, unbroken strands that run parallel within a composite material, offering superior strength and stiffness compared to discontinuous fibers. These fibers enhance load transfer efficiency and improve mechanical properties such as tensile strength and fatigue resistance. Common continuous fibers include carbon, glass, and aramid, which are extensively used in aerospace, automotive, and sporting goods industries.

Exploring Discontinuous Fiber

Discontinuous fiber consists of short, randomly oriented fiber segments that enhance material toughness and impact resistance compared to continuous fiber composites. These fibers improve manufacturing flexibility and reduce production costs by allowing easier molding of complex shapes without compromising strength significantly. Their use in thermoplastics and metal matrix composites supports applications requiring balanced mechanical performance and lightweight properties.

Key Differences: Continuous vs Discontinuous Fiber

Continuous fibers are long, unbroken strands that provide superior tensile strength and stiffness, commonly used in high-performance composites for aerospace and automotive applications. Discontinuous fibers, shorter and randomly oriented, offer improved impact resistance and ease of molding, making them ideal for cost-effective manufacturing in mass production. The key differences lie in fiber length, mechanical properties, and processing methods, influencing the structural performance and application suitability of composite materials.

Mechanical Properties Comparison

Continuous fibers exhibit superior tensile strength and stiffness compared to discontinuous fibers due to their unbroken length, enabling better load transfer and higher mechanical performance in composite materials. Discontinuous fibers provide improved impact resistance and better isotropic properties but generally offer lower modulus and strength values. The choice between continuous and discontinuous fibers depends on the required balance between mechanical strength, toughness, and manufacturing constraints in fiber-reinforced composites.

Manufacturing Processes Involved

Continuous fiber manufacturing involves processes such as pultrusion and filament winding, which ensure long, unbroken fibers are embedded within composites for enhanced strength and durability. Discontinuous fiber composites use techniques like injection molding and compression molding, where short fiber lengths are mixed and oriented randomly, optimizing ease of processing and cost-efficiency. Advanced robotics and automated machinery are increasingly integrated into both methods to improve precision and scalability in fiber placement and matrix curing.

Applications of Continuous Fiber

Continuous fiber composites are extensively utilized in aerospace, automotive, and sporting goods industries due to their superior tensile strength and stiffness compared to discontinuous fibers. These fibers enable the manufacturing of lightweight, high-performance components such as aircraft wings, drive shafts, and racing bicycle frames. Their unbroken fiber length provides enhanced load transfer efficiency and improved fatigue resistance essential for critical structural applications.

Uses of Discontinuous Fiber

Discontinuous fibers are widely used in composite materials where complex shapes and high impact resistance are required, such as automotive parts, aerospace components, and sporting goods. Their shorter length allows for easier processing and molding, making them ideal for injection molding applications. These fibers enhance toughness and isotropic properties in composites, providing balanced mechanical performance in multiple directions.

Advantages and Limitations

Continuous fiber composites exhibit superior tensile strength, stiffness, and load-bearing capabilities due to uninterrupted fiber lengths, making them ideal for structural applications in aerospace and automotive industries. Discontinuous fibers offer enhanced processability, cost-effectiveness, and improved isotropic properties but suffer from reduced mechanical strength and lower impact resistance compared to continuous fibers. The trade-off between mechanical performance and manufacturing flexibility dictates material selection based on application-specific requirements and economic constraints.

Selecting the Right Fiber for Your Application

Continuous fibers offer superior mechanical strength and load-bearing capacity, making them ideal for high-performance composite materials in aerospace and automotive applications. Discontinuous fibers provide enhanced isotropic properties and ease of processing, suitable for injection molding and complex shapes where uniform fiber distribution is critical. Selecting the right fiber depends on the balance between strength requirements, manufacturing process, and end-use application demands.

Continuous Fiber vs Discontinuous Fiber Infographic

materialdif.com

materialdif.com