Glass fiber offers excellent flexibility and cost-efficiency, making it ideal for applications requiring moderate strength and impact resistance. Carbon fiber provides superior strength-to-weight ratio, stiffness, and durability, favored in high-performance industries such as aerospace and automotive engineering. Both materials differ significantly in weight, strength, and price, influencing their suitability based on specific performance and budget requirements.

Table of Comparison

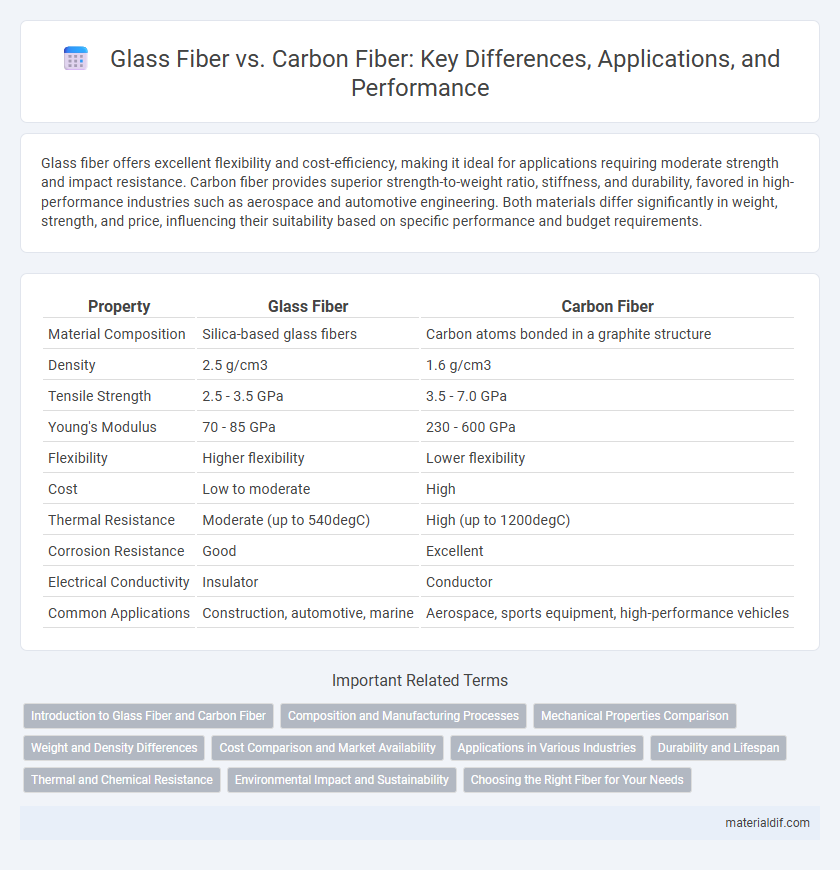

| Property | Glass Fiber | Carbon Fiber |

|---|---|---|

| Material Composition | Silica-based glass fibers | Carbon atoms bonded in a graphite structure |

| Density | 2.5 g/cm3 | 1.6 g/cm3 |

| Tensile Strength | 2.5 - 3.5 GPa | 3.5 - 7.0 GPa |

| Young's Modulus | 70 - 85 GPa | 230 - 600 GPa |

| Flexibility | Higher flexibility | Lower flexibility |

| Cost | Low to moderate | High |

| Thermal Resistance | Moderate (up to 540degC) | High (up to 1200degC) |

| Corrosion Resistance | Good | Excellent |

| Electrical Conductivity | Insulator | Conductor |

| Common Applications | Construction, automotive, marine | Aerospace, sports equipment, high-performance vehicles |

Introduction to Glass Fiber and Carbon Fiber

Glass fiber consists of fine strands of glass woven into fabric, known for its high tensile strength, lightweight properties, and excellent insulation capabilities, making it ideal for composites in automotive and construction industries. Carbon fiber is composed of thin, strong crystalline filaments of carbon, offering superior stiffness, fatigue resistance, and low weight, widely used in aerospace, sports equipment, and high-performance applications. Both materials provide unique mechanical properties suited for different engineering requirements, with glass fiber being cost-effective and corrosion-resistant, while carbon fiber excels in strength-to-weight ratio and durability.

Composition and Manufacturing Processes

Glass fiber is composed primarily of silica-based glass and is produced through a direct melt spinning process where molten glass is extruded into fine filaments. Carbon fiber consists mainly of carbon atoms arranged in a crystalline structure derived from precursor materials such as polyacrylonitrile (PAN) or pitch, and is manufactured through complex pyrolysis and carbonization processes at high temperatures. The differing compositions and manufacturing methods result in variations in mechanical properties, cost, and application suitability between the two fibers.

Mechanical Properties Comparison

Glass fiber offers high tensile strength and excellent flexibility, making it ideal for applications requiring impact resistance and durability. Carbon fiber provides superior stiffness, higher tensile strength-to-weight ratio, and exceptional fatigue resistance, which is critical for aerospace and high-performance engineering. While glass fiber is more cost-effective, carbon fiber outperforms in mechanical properties such as modulus of elasticity and tensile strength.

Weight and Density Differences

Glass fiber has a density of approximately 2.5 g/cm3, making it heavier compared to carbon fiber, which has a density around 1.6 g/cm3. This significant difference in density directly affects the overall weight of composites, with carbon fiber providing a lighter alternative for applications requiring high strength-to-weight ratios. The lower weight of carbon fiber makes it ideal for aerospace, automotive, and sports equipment where reducing mass is critical.

Cost Comparison and Market Availability

Glass fiber is significantly more affordable than carbon fiber, making it the preferred choice for cost-sensitive applications across automotive, construction, and sports equipment industries. Carbon fiber, while offering superior strength-to-weight ratios and stiffness, commands a premium price due to its complex manufacturing process and limited raw material availability. Globally, glass fiber benefits from widespread production facilities and abundant supply chains, whereas carbon fiber's market availability remains constrained, contributing to higher lead times and costs.

Applications in Various Industries

Glass fiber is widely used in construction, automotive, and marine industries due to its cost-effectiveness, high tensile strength, and excellent corrosion resistance. Carbon fiber is preferred in aerospace, sports equipment, and high-performance automotive sectors for its superior stiffness, lightweight properties, and exceptional fatigue resistance. Both fibers enhance product durability and performance, but carbon fiber's higher price limits its use to applications requiring advanced mechanical properties.

Durability and Lifespan

Glass fiber exhibits excellent durability with high resistance to corrosion, impact, and fatigue, making it ideal for environments requiring long-term stability. Carbon fiber offers superior strength-to-weight ratio and exceptional lifespan, maintaining structural integrity under extreme stress and temperature variations. Both materials provide extended service life, but carbon fiber generally outperforms glass fiber in durability under high-performance applications.

Thermal and Chemical Resistance

Glass fiber exhibits superior thermal resistance with the ability to withstand temperatures up to 600degC, making it ideal for high-temperature applications. Carbon fiber offers excellent chemical resistance against most acids and alkalis, although it may degrade under strong oxidizing agents. For environments requiring durable thermal stability, glass fiber is preferred, while carbon fiber suits chemically aggressive conditions with moderate heat exposure.

Environmental Impact and Sustainability

Glass fiber production consumes more energy and generates higher greenhouse gas emissions compared to carbon fiber manufacturing, impacting overall environmental sustainability. Carbon fiber offers superior strength-to-weight ratio that improves fuel efficiency in transportation, contributing to lower carbon footprints over product lifecycles. Recycling challenges persist for both materials, but advancements in carbon fiber recycling technology offer promise for reducing landfill waste and enhancing sustainability.

Choosing the Right Fiber for Your Needs

Glass fiber offers excellent tensile strength, corrosion resistance, and cost-effectiveness, making it ideal for applications such as construction, automotive parts, and marine vessels. Carbon fiber provides superior stiffness, higher strength-to-weight ratio, and enhanced durability, which suits aerospace, high-performance sports equipment, and luxury automotive sectors. Selecting the right fiber depends on factors like budget constraints, required mechanical properties, environmental exposure, and weight optimization needs.

Glass Fiber vs Carbon Fiber Infographic

materialdif.com

materialdif.com