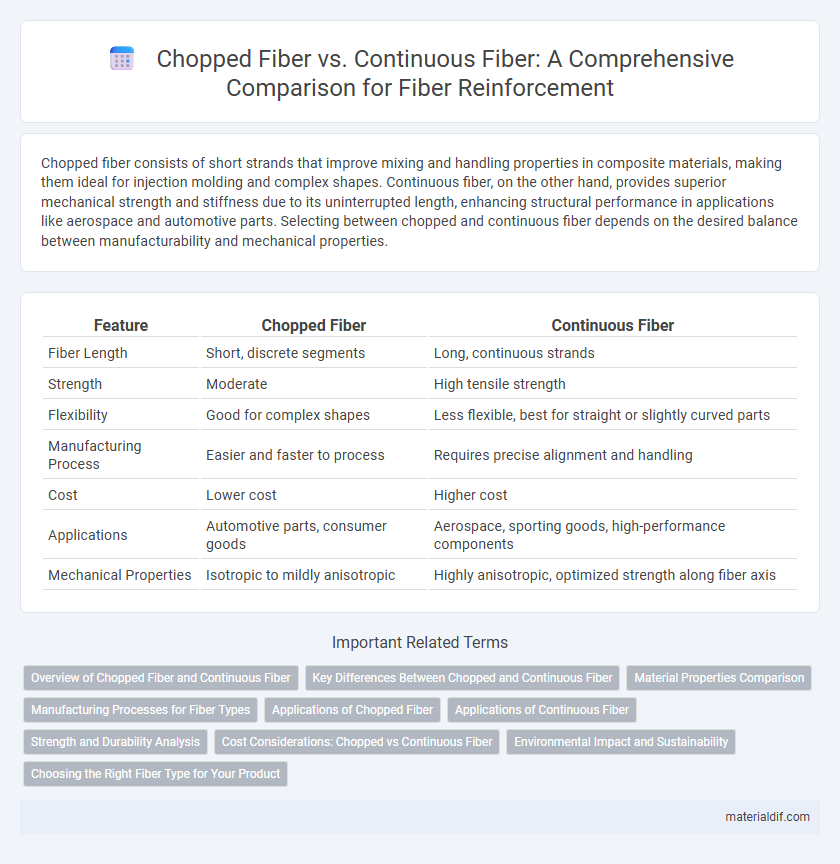

Chopped fiber consists of short strands that improve mixing and handling properties in composite materials, making them ideal for injection molding and complex shapes. Continuous fiber, on the other hand, provides superior mechanical strength and stiffness due to its uninterrupted length, enhancing structural performance in applications like aerospace and automotive parts. Selecting between chopped and continuous fiber depends on the desired balance between manufacturability and mechanical properties.

Table of Comparison

| Feature | Chopped Fiber | Continuous Fiber |

|---|---|---|

| Fiber Length | Short, discrete segments | Long, continuous strands |

| Strength | Moderate | High tensile strength |

| Flexibility | Good for complex shapes | Less flexible, best for straight or slightly curved parts |

| Manufacturing Process | Easier and faster to process | Requires precise alignment and handling |

| Cost | Lower cost | Higher cost |

| Applications | Automotive parts, consumer goods | Aerospace, sporting goods, high-performance components |

| Mechanical Properties | Isotropic to mildly anisotropic | Highly anisotropic, optimized strength along fiber axis |

Overview of Chopped Fiber and Continuous Fiber

Chopped fiber consists of short, discrete strands typically ranging from 3 to 50 millimeters in length, offering enhanced moldability and uniform dispersion within composite matrices. Continuous fiber comprises long, unbroken strands that provide superior tensile strength and stiffness, commonly used in high-performance applications such as aerospace and automotive components. Selecting between chopped and continuous fiber depends on desired mechanical properties and manufacturing processes, with chopped fibers favoring ease of processing and continuous fibers delivering optimal structural reinforcement.

Key Differences Between Chopped and Continuous Fiber

Chopped fiber consists of short, discrete lengths typically ranging from a few millimeters to several centimeters, enhancing isotropic properties and ease of processing in composite materials. Continuous fiber, by contrast, maintains an unbroken length, offering superior tensile strength and load-bearing capacity, essential for high-performance applications like aerospace and automotive components. The key differences lie in mechanical performance, manufacturing methods, and application suitability, where chopped fibers enable complex shapes and cost-effectiveness, while continuous fibers deliver maximal strength and structural integrity.

Material Properties Comparison

Chopped fiber offers improved isotropic properties and easier molding for complex shapes, but exhibits lower tensile strength and stiffness compared to continuous fiber, which provides superior mechanical performance and enhanced load transfer due to its unbroken fiber length. Continuous fibers deliver higher impact resistance and fatigue life, making them ideal for high-performance composite materials, whereas chopped fibers are favored in applications requiring cost efficiency and simplified processing. The choice between chopped and continuous fibers depends on balancing material strength requirements with manufacturing flexibility and economic considerations.

Manufacturing Processes for Fiber Types

Chopped fiber involves short lengths of fiber typically used in injection molding and compression molding, allowing for faster processing and easier handling in mass production. Continuous fiber, characterized by long, unbroken strands, is primarily used in processes like filament winding, pultrusion, and automated fiber placement to achieve superior mechanical properties. Manufacturing continuous fiber composites requires precise fiber alignment and impregnation techniques to maximize strength and stiffness.

Applications of Chopped Fiber

Chopped fiber is extensively used in injection molding and compression molding processes due to its ease of handling and ability to reinforce complex part geometries. Its short length allows for better flow and uniform dispersion within polymer matrices, making it ideal for automotive components, consumer goods, and electrical housings. Compared to continuous fiber, chopped fiber offers cost-effective reinforcement while enabling mass production of lightweight, high-strength composite parts.

Applications of Continuous Fiber

Continuous fiber offers superior mechanical strength and flexibility, making it ideal for aerospace, automotive, and construction applications requiring high-performance composites. Its uninterrupted fiber length enhances load distribution and impact resistance in structural components such as aircraft wings, automotive body panels, and wind turbine blades. Continuous fiber composites also excel in sports equipment and marine industries, delivering lightweight durability and improved fatigue resistance.

Strength and Durability Analysis

Chopped fiber composites exhibit lower tensile strength and reduced durability due to shorter fiber lengths and weaker fiber-matrix bonding compared to continuous fiber composites. Continuous fibers provide superior load transfer and resistance to crack propagation, resulting in enhanced mechanical strength and long-term structural integrity. Consequently, continuous fiber reinforcements are preferred in applications demanding high performance and extended service life.

Cost Considerations: Chopped vs Continuous Fiber

Chopped fiber generally offers lower material and processing costs due to its easier handling and compatibility with automated manufacturing methods, reducing labor and production time. Continuous fiber delivers superior mechanical properties but involves higher costs related to more complex fabrication techniques and longer cycle times. Balancing cost considerations with performance requirements is crucial when selecting between chopped and continuous fiber for composite applications.

Environmental Impact and Sustainability

Chopped fiber and continuous fiber differ significantly in their environmental impact and sustainability, with chopped fiber typically requiring less energy for processing and generating lower carbon emissions due to shorter production cycles. Continuous fiber offers superior mechanical properties, enabling longer-lasting and more durable composite materials that reduce the need for frequent replacements, indirectly supporting sustainability. The choice between chopped and continuous fiber depends on balancing resource efficiency with product lifespan to optimize environmental benefits.

Choosing the Right Fiber Type for Your Product

Choosing between chopped fiber and continuous fiber depends on the desired strength, flexibility, and application of your product. Continuous fibers offer superior tensile strength and are ideal for high-performance composites requiring consistent reinforcement, while chopped fibers provide easier processing and better distribution in molded parts. Evaluating factors such as mechanical requirements, manufacturing methods, and cost constraints will guide you in selecting the most suitable fiber type for optimal product performance.

Chopped Fiber vs Continuous Fiber Infographic

materialdif.com

materialdif.com