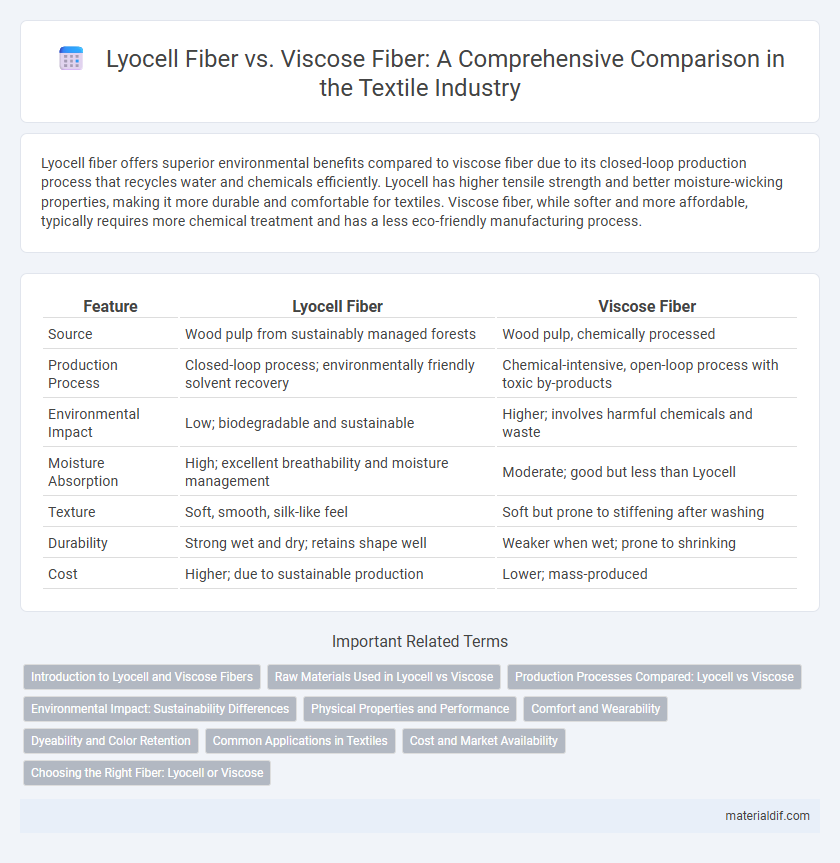

Lyocell fiber offers superior environmental benefits compared to viscose fiber due to its closed-loop production process that recycles water and chemicals efficiently. Lyocell has higher tensile strength and better moisture-wicking properties, making it more durable and comfortable for textiles. Viscose fiber, while softer and more affordable, typically requires more chemical treatment and has a less eco-friendly manufacturing process.

Table of Comparison

| Feature | Lyocell Fiber | Viscose Fiber |

|---|---|---|

| Source | Wood pulp from sustainably managed forests | Wood pulp, chemically processed |

| Production Process | Closed-loop process; environmentally friendly solvent recovery | Chemical-intensive, open-loop process with toxic by-products |

| Environmental Impact | Low; biodegradable and sustainable | Higher; involves harmful chemicals and waste |

| Moisture Absorption | High; excellent breathability and moisture management | Moderate; good but less than Lyocell |

| Texture | Soft, smooth, silk-like feel | Soft but prone to stiffening after washing |

| Durability | Strong wet and dry; retains shape well | Weaker when wet; prone to shrinking |

| Cost | Higher; due to sustainable production | Lower; mass-produced |

Introduction to Lyocell and Viscose Fibers

Lyocell fiber is a type of regenerated cellulose fiber made from dissolving wood pulp using a non-toxic solvent, known for its eco-friendly production and biodegradable properties. Viscose fiber, also derived from cellulose, is produced through a chemical-intensive process involving carbon disulfide and sodium hydroxide, making it less sustainable. Both fibers are widely used in textiles, offering softness and breathability, but Lyocell is favored for its superior strength and environmental benefits compared to viscose.

Raw Materials Used in Lyocell vs Viscose

Lyocell fiber is derived from sustainably sourced wood pulp, primarily from eucalyptus, beech, and spruce trees, using a closed-loop solvent spinning process that recycles nearly all chemicals and water. In contrast, viscose fiber is produced from chemically treated cellulose obtained from wood pulp, often using toxic chemicals like carbon disulfide and sulfuric acid, which can harm the environment. Lyocell's raw materials and manufacturing emphasize eco-friendliness and sustainability, whereas viscose involves more intensive chemical processing and environmental impact.

Production Processes Compared: Lyocell vs Viscose

Lyocell fiber is produced through a closed-loop process using non-toxic solvents, making it more environmentally friendly compared to viscose fiber, which employs chemicals like carbon disulfide that pose environmental and health risks. The lyocell production process involves dissolving cellulose in N-Methylmorpholine N-oxide (NMMO), with almost complete solvent recovery and minimal waste. In contrast, viscose production requires extensive chemical processing steps, including steeping, shredding, and regeneration, resulting in higher water usage and pollutant discharge.

Environmental Impact: Sustainability Differences

Lyocell fiber is produced through a closed-loop process that recycles water and solvents, significantly reducing environmental pollution compared to viscose fiber, which involves a chemically intensive method releasing harmful effluents. Lyocell's biodegradability and lower water consumption contribute to its status as a more sustainable textile option. Viscose fiber production often results in deforestation and higher carbon emissions, making it less eco-friendly than lyocell in terms of sustainability.

Physical Properties and Performance

Lyocell fiber exhibits higher tensile strength and superior moisture absorption compared to viscose fiber, enhancing durability and comfort in textile applications. Unlike viscose, Lyocell maintains its physical integrity when wet, making it ideal for activewear and performance garments. Its smooth surface reduces pilling and increases wrinkle resistance, offering longer-lasting fabric quality.

Comfort and Wearability

Lyocell fiber offers superior moisture-wicking properties and breathability compared to viscose fiber, enhancing overall comfort during wear. Its smooth, soft texture reduces skin irritation, making it ideal for sensitive skin and long-term use. Unlike viscose, lyocell maintains durability and shape after multiple washes, ensuring consistent wearability and performance.

Dyeability and Color Retention

Lyocell fiber exhibits superior dyeability compared to viscose fiber due to its smooth surface and higher degree of polymer crystallinity, allowing for more uniform and intense color absorption. Lyocell also demonstrates enhanced color retention, maintaining vibrancy after multiple washes because of its stronger fiber structure and resistance to fading. In contrast, viscose fibers tend to lose color faster and may suffer from uneven dye uptake, resulting in diminished fabric appearance over time.

Common Applications in Textiles

Lyocell fiber is widely used in high-performance activewear, denim, and luxury bed linens due to its moisture-wicking, breathable, and eco-friendly properties. Viscose fiber is commonly found in affordable fashion garments, linings, and upholstery fabrics because of its soft texture, vibrant dyeability, and cost-effectiveness. Both fibers serve distinct market segments, with Lyocell favored for sustainability and performance textiles, while Viscose dominates mass-produced apparel and interior textiles.

Cost and Market Availability

Lyocell fiber generally costs more than viscose fiber due to its environmentally friendly closed-loop production process and superior sustainability credentials. Viscose fiber is widely available and dominates the market because of its lower price and established manufacturing infrastructure. The higher cost of lyocell limits its use primarily to premium textiles, while viscose remains popular in mass-produced apparel and home textiles.

Choosing the Right Fiber: Lyocell or Viscose

Choosing the right fiber depends on sustainability and performance factors; Lyocell fiber, derived from wood pulp through a closed-loop process, offers superior biodegradability and moisture management compared to viscose. Viscose fiber, while cost-effective and soft, involves chemical-intensive production that impacts environmental footprint and durability. Prioritizing Lyocell supports eco-friendly textile manufacturing with enhanced strength and reduced environmental impact, making it ideal for sustainable fashion applications.

Lyocell Fiber vs Viscose Fiber Infographic

materialdif.com

materialdif.com