Short-staple fiber in fiber PET offers enhanced softness and breathability, making it ideal for lightweight textiles and comfort-focused apparel. Long-staple fiber provides superior strength, durability, and a smoother finish, which benefits high-performance fabrics and garments requiring longevity. Selecting between short-staple and long-staple fibers depends on the desired balance of texture, durability, and end-use application in fiber PET products.

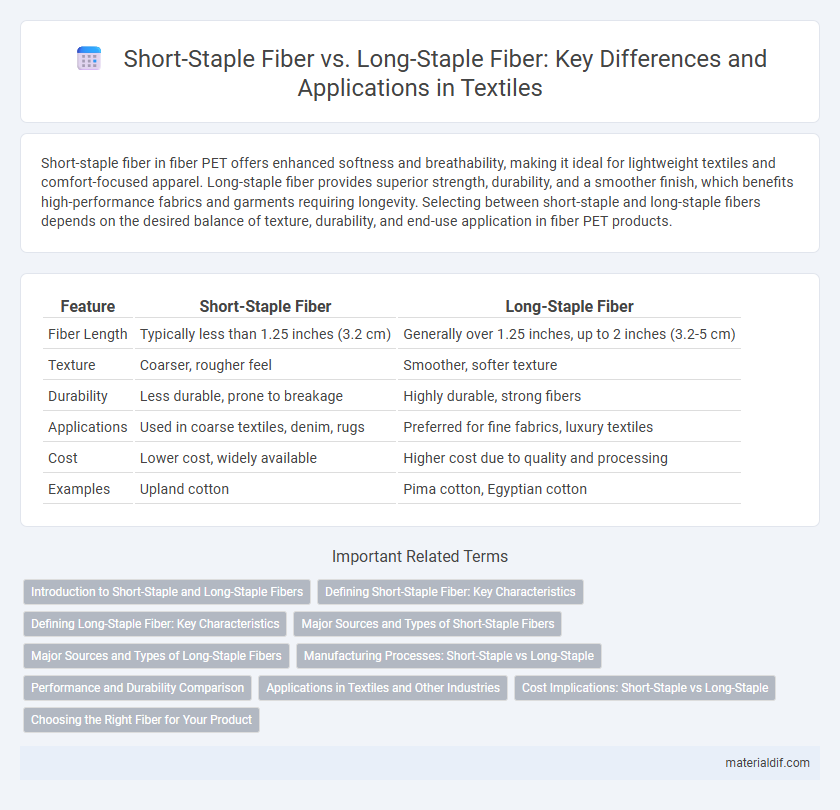

Table of Comparison

| Feature | Short-Staple Fiber | Long-Staple Fiber |

|---|---|---|

| Fiber Length | Typically less than 1.25 inches (3.2 cm) | Generally over 1.25 inches, up to 2 inches (3.2-5 cm) |

| Texture | Coarser, rougher feel | Smoother, softer texture |

| Durability | Less durable, prone to breakage | Highly durable, strong fibers |

| Applications | Used in coarse textiles, denim, rugs | Preferred for fine fabrics, luxury textiles |

| Cost | Lower cost, widely available | Higher cost due to quality and processing |

| Examples | Upland cotton | Pima cotton, Egyptian cotton |

Introduction to Short-Staple and Long-Staple Fibers

Short-staple fibers typically measure less than 1.25 inches and are known for their staple strength and versatility in producing soft, durable textiles. Long-staple fibers, usually exceeding 1.5 inches, yield smoother, stronger yarns with enhanced fiber alignment, resulting in higher quality fabrics like Egyptian cotton or Pima cotton. Understanding the intrinsic length difference aids textile manufacturers in selecting appropriate fiber types for applications ranging from mass-produced garments to luxury products.

Defining Short-Staple Fiber: Key Characteristics

Short-staple fiber refers to natural fibers with a staple length typically under 1.25 inches (3.2 cm), commonly found in cotton varieties such as Upland cotton. These fibers are characterized by their shorter length, resulting in textiles that are soft but may exhibit lower tensile strength and durability compared to long-staple fibers. The short fiber length affects spinning performance and fabric quality, often producing fabrics with a fuzzier surface and increased pilling tendency.

Defining Long-Staple Fiber: Key Characteristics

Long-staple fiber is characterized by its longer fiber length, typically exceeding 1.25 inches, which results in stronger and smoother yarns. It possesses superior tensile strength and resilience, making it ideal for high-quality textiles and garments. This fiber type offers enhanced durability and a luxurious finish compared to shorter staple fibers.

Major Sources and Types of Short-Staple Fibers

Short-staple fibers, typically measuring less than 1.25 inches, are predominantly sourced from cotton varieties such as Upland cotton, which accounts for approximately 90% of global cotton production. Other notable short-staple fibers include certain types of wool from breeds like Merino and Zwartble, renowned for their fine and curly fibers. These fibers are favored for their softness and versatility, commonly used in textiles requiring a smooth finish and high durability.

Major Sources and Types of Long-Staple Fibers

Long-staple fibers, known for their superior strength and smoothness, primarily come from cotton varieties such as Pima, Egyptian, and Sea Island cotton. These fibers typically measure over 1 3/8 inches in length, enabling the production of finer, more durable textiles compared to short-staple fibers. Major sources of long-staple fibers include regions with ideal growing conditions like Egypt, the southwestern United States, and the Caribbean, where climatic factors contribute to the development of premium fiber quality.

Manufacturing Processes: Short-Staple vs Long-Staple

Short-staple fiber manufacturing involves carding and combing to align shorter fiber lengths for spinning, resulting in yarn quicker but with a fuzzier texture and lower tensile strength. Long-staple fiber processing emphasizes careful combing and spinning techniques to preserve fiber length, producing smoother, stronger yarn ideal for high-quality textiles. The choice between short-staple and long-staple fiber manufacturing impacts fabric durability, softness, and final product applications in apparel and home textiles.

Performance and Durability Comparison

Long-staple fiber exhibits superior performance and durability due to its longer length, which enhances tensile strength and reduces fiber breakage during processing. Short-staple fiber tends to produce weaker yarns with lower abrasion resistance, resulting in less durable fabrics. Consequently, long-staple fiber is preferred in high-quality textiles where longevity and strength are critical.

Applications in Textiles and Other Industries

Short-staple fiber, characterized by fibers typically less than 1.25 inches, is widely used in the production of denim, flannel, and towels due to its ability to produce soft, breathable textiles with a slightly coarse texture. Long-staple fiber, exceeding 1.25 inches in length, is preferred in luxury fabrics like Egyptian cotton linens and high-quality bed sheets for its strength, smoothness, and durability. Beyond textiles, long-staple fibers are valuable in industrial applications such as filter manufacturing and composite materials, while short-staple fibers find use in insulation and paper products.

Cost Implications: Short-Staple vs Long-Staple

Short-staple fiber typically incurs lower production and processing costs due to its faster growth cycle and more abundant availability, making it a cost-effective choice for mass-market textiles. In contrast, long-staple fiber commands higher prices because of its superior strength, finer texture, and more labor-intensive cultivation, which drives up manufacturing expenses. Businesses aiming for premium quality products often accept the elevated costs associated with long-staple fibers to achieve enhanced durability and luxury appeal.

Choosing the Right Fiber for Your Product

Short-staple fiber, such as upland cotton, offers affordability and versatility, making it ideal for everyday textiles and heavier fabrics. Long-staple fiber, including Egyptian and Pima cotton, provides superior strength, softness, and durability, perfect for luxury garments and high-quality bedding. Selecting the right fiber depends on the desired texture, durability, and price point of your final product.

Short-staple fiber vs Long-staple fiber Infographic

materialdif.com

materialdif.com