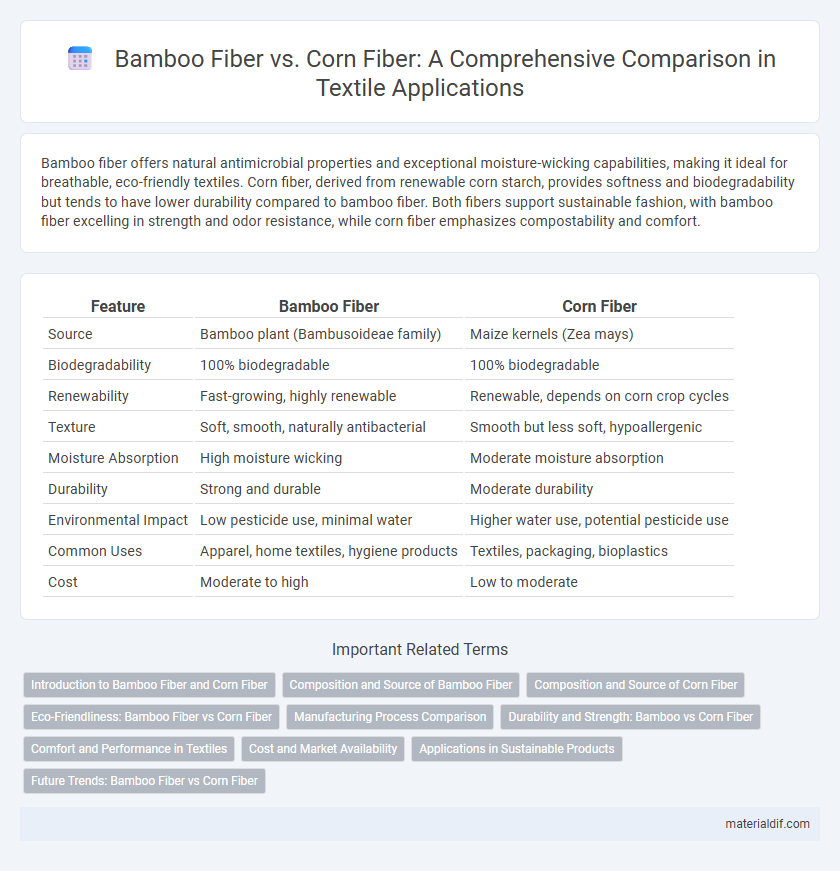

Bamboo fiber offers natural antimicrobial properties and exceptional moisture-wicking capabilities, making it ideal for breathable, eco-friendly textiles. Corn fiber, derived from renewable corn starch, provides softness and biodegradability but tends to have lower durability compared to bamboo fiber. Both fibers support sustainable fashion, with bamboo fiber excelling in strength and odor resistance, while corn fiber emphasizes compostability and comfort.

Table of Comparison

| Feature | Bamboo Fiber | Corn Fiber |

|---|---|---|

| Source | Bamboo plant (Bambusoideae family) | Maize kernels (Zea mays) |

| Biodegradability | 100% biodegradable | 100% biodegradable |

| Renewability | Fast-growing, highly renewable | Renewable, depends on corn crop cycles |

| Texture | Soft, smooth, naturally antibacterial | Smooth but less soft, hypoallergenic |

| Moisture Absorption | High moisture wicking | Moderate moisture absorption |

| Durability | Strong and durable | Moderate durability |

| Environmental Impact | Low pesticide use, minimal water | Higher water use, potential pesticide use |

| Common Uses | Apparel, home textiles, hygiene products | Textiles, packaging, bioplastics |

| Cost | Moderate to high | Low to moderate |

Introduction to Bamboo Fiber and Corn Fiber

Bamboo fiber, derived from the pulp of bamboo plants, is known for its natural antibacterial properties, breathability, and eco-friendly sustainability compared to synthetic fibers. Corn fiber, produced from the cellulose of cornstarch, offers biodegradability, softness, and moisture-wicking capabilities, making it a renewable option in textile manufacturing. Both fibers provide biodegradable alternatives to traditional fabrics, with bamboo emphasizing durability and antimicrobial benefits, while corn fiber stands out for its comfort and environmental impact.

Composition and Source of Bamboo Fiber

Bamboo fiber consists primarily of cellulose extracted from bamboo plants, which are fast-growing grasses rich in natural polymers suitable for textile production. Unlike corn fiber, derived from polylactic acid (PLA) made through the fermentation of corn starch, bamboo fiber is obtained by mechanically or chemically processing bamboo stalks, preserving its lignin and hemicellulose content. The sustainable and renewable nature of bamboo as a source enhances its appeal for eco-friendly fiber manufacturing compared to corn-based fibers.

Composition and Source of Corn Fiber

Bamboo fiber is primarily composed of cellulose with natural antibacterial properties, sourced from the bamboo plant's woody stalks through a mechanical or chemical process. Corn fiber, derived from corn kernels and byproducts of corn starch production, is rich in cellulose and hemicellulose, offering a biodegradable and sustainable alternative. The composition of corn fiber includes key polysaccharides ideal for creating lightweight, absorbent textiles and bioplastics.

Eco-Friendliness: Bamboo Fiber vs Corn Fiber

Bamboo fiber is highly eco-friendly due to its rapid growth, minimal pesticide use, and low water consumption, making it a sustainable textile option. Corn fiber, also known as PLA fiber, is biodegradable and derived from renewable resources but often requires significant agricultural input and processing energy. Comparing the two, bamboo fiber offers superior environmental benefits through natural growth and easier biodegradability, while corn fiber's eco-friendliness depends heavily on production practices and end-of-life management.

Manufacturing Process Comparison

Bamboo fiber manufacturing involves mechanical or chemical processes where bamboo pulp is softened, crushed, and then formed into fiber, often requiring fewer chemicals in mechanical methods but more energy in chemical treatments. Corn fiber, derived primarily from cornstarch, undergoes a fermentation and extrusion process to produce biodegradable fibers, emphasizing eco-friendly solvents and lower water usage. Both fibers highlight sustainability, yet bamboo relies on natural cellulose extraction, while corn fiber leverages renewable agricultural byproducts and advanced biopolymer technology.

Durability and Strength: Bamboo vs Corn Fiber

Bamboo fiber exhibits superior durability and strength compared to corn fiber due to its natural lignin and cellulose composition, which enhances tensile resistance and longevity in textile applications. Corn fiber, derived from polylactic acid (PLA), tends to be less durable under prolonged stress and is more prone to degradation and wear over time. The intrinsic molecular structure of bamboo fiber provides better performance in terms of elasticity and abrasion resistance, making it preferable for high-stress fabric uses.

Comfort and Performance in Textiles

Bamboo fiber offers superior moisture-wicking and antibacterial properties, enhancing comfort and keeping textiles fresh throughout the day. Corn fiber, derived from renewable polylactic acid, excels in softness and breathability, providing lightweight performance for active wear. Both fibers contribute eco-friendly benefits, but bamboo's natural durability often leads to longer-lasting, comfortable garments compared to corn fiber's biodegradable advantages.

Cost and Market Availability

Bamboo fiber is generally more cost-effective due to its rapid growth rate and sustainable harvesting methods, making it readily available in the global market, especially in Asia. Corn fiber, derived from corn husks and stalks, tends to be more expensive due to the complexity of extraction processes and limited large-scale production. Market availability of corn fiber remains relatively niche compared to the widespread accessibility of bamboo fiber, which benefits from established supply chains and growing consumer demand for eco-friendly textiles.

Applications in Sustainable Products

Bamboo fiber is widely used in textiles, packaging, and biodegradable composites due to its natural antibacterial properties and rapid renewability, making it ideal for eco-friendly clothing and sustainable home goods. Corn fiber excels in producing biodegradable plastics and food packaging films, offering compostable alternatives to traditional petroleum-based materials while supporting circular economy goals. Both fibers contribute significantly to reducing environmental impact through renewable sourcing and compatibility with sustainable manufacturing processes.

Future Trends: Bamboo Fiber vs Corn Fiber

Bamboo fiber and corn fiber each exhibit promising potentials in sustainable textile production, with bamboo fiber favored for its natural antibacterial properties and rapid renewability, while corn fiber gains attention for its biodegradability and compatibility with bio-based polymers. Emerging innovations in fiber blending and enhanced processing technologies are driving the adoption of both, but market trends indicate faster growth in corn fiber applications due to its versatility in bioplastics and eco-friendly packaging. Environmental impact assessments highlight bamboo's lower water usage, contrasting with corn's dependence on agricultural practices, which influences future scalability and consumer preferences in eco-conscious markets.

Bamboo fiber vs Corn fiber Infographic

materialdif.com

materialdif.com