Short fiber offers improved surface finish and easier processing in composite materials, while long fiber provides superior mechanical strength and impact resistance. The choice between short fiber and long fiber depends on the application's structural requirements and manufacturing methods. Optimizing fiber length enhances performance attributes such as durability, weight reduction, and cost-efficiency in fiber-reinforced products.

Table of Comparison

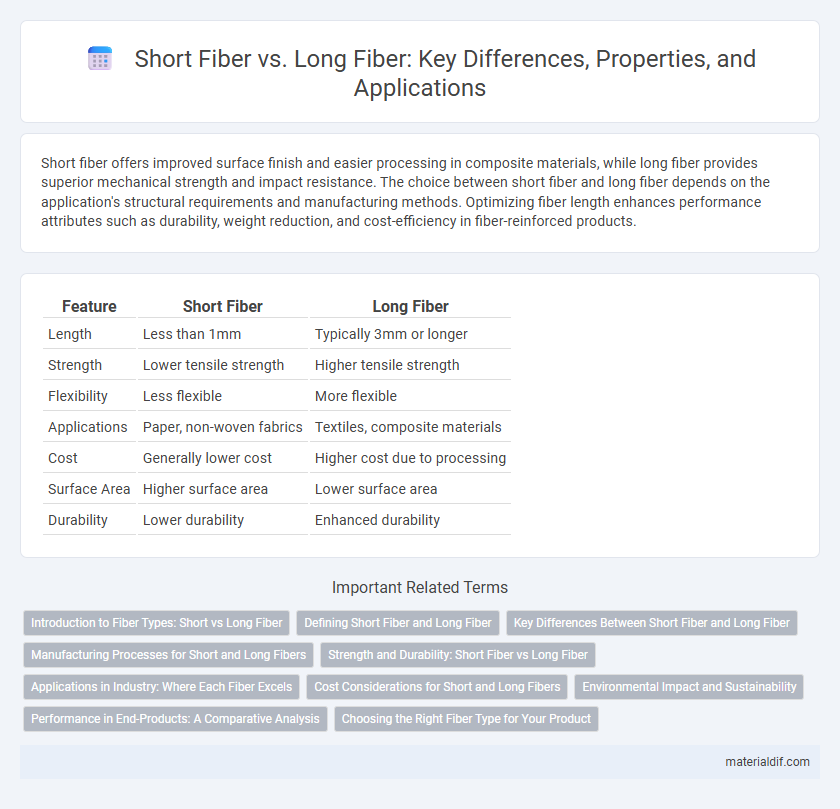

| Feature | Short Fiber | Long Fiber |

|---|---|---|

| Length | Less than 1mm | Typically 3mm or longer |

| Strength | Lower tensile strength | Higher tensile strength |

| Flexibility | Less flexible | More flexible |

| Applications | Paper, non-woven fabrics | Textiles, composite materials |

| Cost | Generally lower cost | Higher cost due to processing |

| Surface Area | Higher surface area | Lower surface area |

| Durability | Lower durability | Enhanced durability |

Introduction to Fiber Types: Short vs Long Fiber

Short fibers, typically measuring less than 1.5 inches, enhance fabric softness and are commonly used in staple fiber production, while long fibers, often exceeding 2.5 inches, contribute to durability and strength in yarns and textiles. The selection between short and long fibers directly impacts the end product's texture, tensile strength, and overall performance. Understanding the distinct characteristics of these fiber types is essential for optimizing manufacturing processes and achieving desired fabric qualities.

Defining Short Fiber and Long Fiber

Short fiber refers to fibers with a staple length typically less than 1.5 inches, commonly used in soft textiles and nonwoven fabrics for enhanced flexibility and softness. Long fiber, or filament fiber, generally exceeds several inches in length, providing superior strength and durability suitable for high-performance textiles and composites. The distinction between short and long fibers significantly influences fabric texture, tensile strength, and application versatility in the textile industry.

Key Differences Between Short Fiber and Long Fiber

Short fiber typically measures less than 12 millimeters and offers higher surface area, enhancing bonding in paper production, while long fiber exceeds 12 millimeters, providing superior strength and durability. The key differences lie in fiber length, which directly affects tensile strength, flexibility, and texture of the final product. Long fibers are preferred for high-strength applications such as textiles and heavy-duty paper, whereas short fibers are ideal for smooth surfaces and fine detailing.

Manufacturing Processes for Short and Long Fibers

Short fiber manufacturing processes typically involve mechanical cutting or shredding of continuous fibers into shorter lengths, enabling easier mixing and molding in composite production. Long fiber production often requires continuous extrusion or pultrusion techniques, maintaining fiber length for enhanced tensile strength and durability in end products. The choice between short and long fiber methods depends on the desired mechanical properties and processing capabilities of the composite materials.

Strength and Durability: Short Fiber vs Long Fiber

Long fibers provide superior strength and durability due to their continuous length, creating stronger and more resilient materials compared to short fibers. Short fibers tend to produce materials with lower tensile strength and reduced wear resistance because they form weaker bonds and have more fiber ends prone to breakage. In applications requiring high mechanical performance and longevity, long fiber composites are preferred for their enhanced load-bearing capacity and structural integrity.

Applications in Industry: Where Each Fiber Excels

Short fibers offer enhanced surface finish and are ideal for injection molding and small, intricate components in automotive and consumer electronics industries. Long fibers provide superior mechanical strength and stiffness, making them perfect for structural parts in aerospace, construction, and high-performance sports equipment. Selecting the appropriate fiber length optimizes durability, weight reduction, and cost-efficiency in industry-specific manufacturing processes.

Cost Considerations for Short and Long Fibers

Short fibers generally offer lower material costs due to reduced processing requirements and higher production yields, making them a cost-effective choice for mass manufacturing. Long fibers, while more expensive upfront, provide superior mechanical properties and durability, potentially reducing long-term costs through enhanced product performance and lifespan. Evaluating total cost of ownership, including raw material prices, processing complexity, and product application, is essential when deciding between short and long fiber options.

Environmental Impact and Sustainability

Short fiber production generally consumes less water and energy compared to long fiber processing, resulting in a lower carbon footprint and reduced environmental impact. Long fibers, while offering superior durability and strength, often require more intensive chemical treatments and energy use, which can contribute to higher emissions and waste. Sustainable fiber sourcing emphasizes renewable materials and closed-loop manufacturing to minimize ecological damage regardless of fiber length.

Performance in End-Products: A Comparative Analysis

Long fibers enhance end-product performance by improving tensile strength, durability, and resistance to wear, making them ideal for high-stress applications like automotive parts and construction materials. Short fibers, although less robust, provide better surface finish and are more cost-effective, suitable for products requiring fine detail and lightweight properties such as household goods and packaging. The choice between short and long fibers depends on balancing performance demands with manufacturing costs and product specifications.

Choosing the Right Fiber Type for Your Product

Short fibers offer improved surface smoothness and are ideal for products requiring high-density and fine detail, while long fibers provide superior tensile strength and durability suitable for load-bearing applications. Selecting the right fiber type depends on the desired mechanical properties, processing methods, and end-use performance of the product. Evaluating product-specific requirements such as flexibility, strength, and finish quality ensures optimal fiber choice for enhanced functionality and longevity.

Short Fiber vs Long Fiber Infographic

materialdif.com

materialdif.com