Continuous fiber offers superior strength and stiffness compared to chopped fiber due to its unbroken length, which enhances load transfer within composite materials. Chopped fiber, while easier to process and more cost-effective, provides lower mechanical performance but improves moldability and reduces material waste. Selecting between continuous and chopped fiber depends on the desired balance between structural integrity and manufacturing efficiency in composite design.

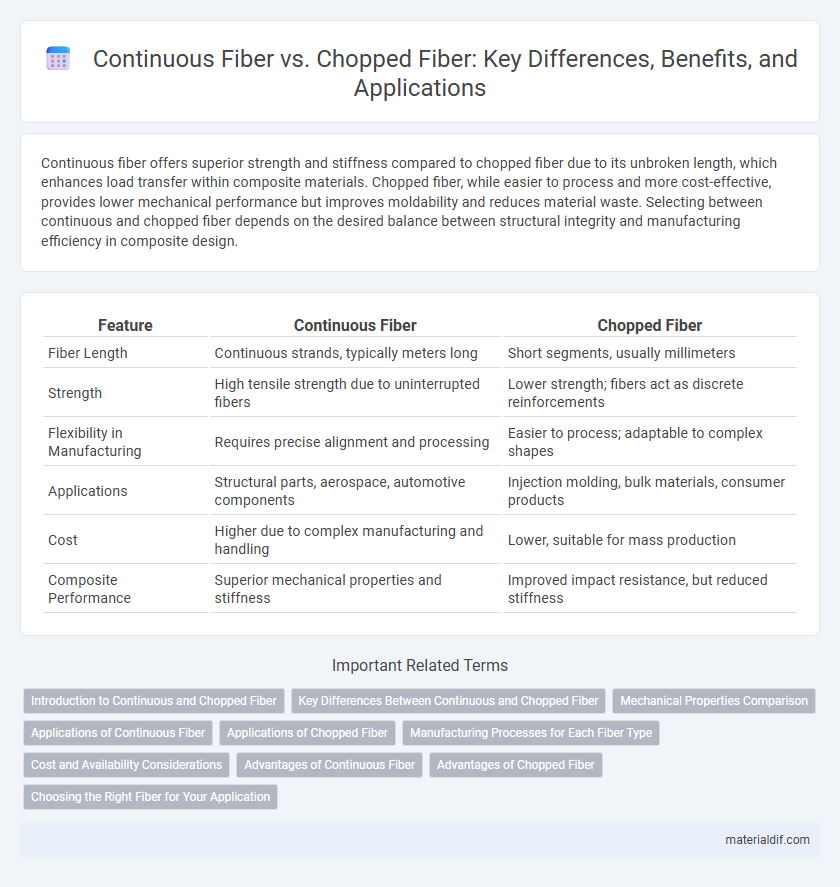

Table of Comparison

| Feature | Continuous Fiber | Chopped Fiber |

|---|---|---|

| Fiber Length | Continuous strands, typically meters long | Short segments, usually millimeters |

| Strength | High tensile strength due to uninterrupted fibers | Lower strength; fibers act as discrete reinforcements |

| Flexibility in Manufacturing | Requires precise alignment and processing | Easier to process; adaptable to complex shapes |

| Applications | Structural parts, aerospace, automotive components | Injection molding, bulk materials, consumer products |

| Cost | Higher due to complex manufacturing and handling | Lower, suitable for mass production |

| Composite Performance | Superior mechanical properties and stiffness | Improved impact resistance, but reduced stiffness |

Introduction to Continuous and Chopped Fiber

Continuous fiber features long, unbroken strands that provide superior tensile strength and durability in composite materials, making them ideal for structural applications. Chopped fiber consists of short, randomly oriented segments that offer easier processing and greater design flexibility but typically result in lower mechanical properties. Both fibers play critical roles in composites, with continuous fiber favored for high-performance uses and chopped fiber preferred for cost-effective, complex shapes.

Key Differences Between Continuous and Chopped Fiber

Continuous fibers offer superior mechanical strength and stiffness due to their uninterrupted length, making them ideal for load-bearing applications. Chopped fibers provide improved moldability and ease of processing in complex shapes, but generally result in lower tensile strength and reduced impact resistance. The choice between continuous and chopped fibers depends on the desired balance between structural performance and manufacturing flexibility.

Mechanical Properties Comparison

Continuous fibers exhibit superior mechanical properties compared to chopped fibers due to their uninterrupted length, which enhances tensile strength, stiffness, and impact resistance. Chopped fibers, being shorter, typically result in composites with lower load-bearing capacity and reduced elongation at break. The continuous fiber arrangement enables efficient stress transfer across the matrix, leading to improved performance in structural applications.

Applications of Continuous Fiber

Continuous fiber offers superior tensile strength and flexibility, making it ideal for high-performance applications such as aerospace components, sporting goods, and automotive parts. Its uninterrupted fibers provide improved load bearing and fatigue resistance compared to chopped fiber, which enhances structural integrity in advanced composites. Industries leverage continuous fiber for manufacturing lightweight, durable materials that optimize performance and safety standards.

Applications of Chopped Fiber

Chopped fiber is widely used in automotive manufacturing for lightweight composite parts, enhancing strength and impact resistance without adding excessive weight. It is also prevalent in construction materials, such as concrete reinforcement, providing improved durability and crack resistance. Additionally, chopped fiber finds applications in consumer goods, including sporting equipment and molded plastic components, due to its versatility and cost-effectiveness.

Manufacturing Processes for Each Fiber Type

Continuous fiber manufacturing involves processes like filament winding, pultrusion, and weaving, where long, unbroken fibers are aligned and embedded in resin matrices for enhanced tensile strength and structural integrity. Chopped fiber production incorporates short fiber segments dispersed into thermoplastic or thermoset resins through injection molding or compression molding techniques, enabling increased design flexibility and faster cycle times. Each manufacturing process affects fiber orientation, mechanical properties, and application suitability in composites used across aerospace, automotive, and sporting goods industries.

Cost and Availability Considerations

Continuous fiber offers superior strength and durability but generally comes at a higher cost due to more complex manufacturing processes and limited availability. Chopped fiber, widely available and more affordable, provides cost-effective reinforcement for applications where ultimate tensile strength is less critical. Choosing between continuous and chopped fiber requires balancing budget constraints with performance requirements in composite material production.

Advantages of Continuous Fiber

Continuous fiber offers superior mechanical properties such as increased tensile strength and enhanced stiffness compared to chopped fiber. Its unbroken length enables better load transfer and improved impact resistance in composite materials. This makes continuous fiber ideal for applications requiring high structural integrity and durability, such as aerospace and automotive components.

Advantages of Chopped Fiber

Chopped fiber offers enhanced moldability and is ideal for complex shapes due to its shorter length and uniform dispersion, improving processing efficiency in composite manufacturing. It provides better surface finish and isotropic mechanical properties compared to continuous fiber, making it suitable for applications requiring balanced strength and flexibility. Additionally, chopped fiber reduces material waste and lowers production costs by facilitating automated processing techniques such as injection molding.

Choosing the Right Fiber for Your Application

Continuous fiber offers superior tensile strength and load-bearing capacity, making it ideal for structural applications requiring high performance and durability. Chopped fiber provides greater uniformity in complex shapes and easier processing at a lower cost, suitable for non-structural components and mass production. Selecting the right fiber depends on balancing performance requirements, manufacturing methods, and budget constraints to optimize the application's efficiency and longevity.

Continuous Fiber vs Chopped Fiber Infographic

materialdif.com

materialdif.com