Regenerated fibers are derived from natural polymers such as cellulose, undergoing chemical processes to transform raw materials like wood pulp into fibers like viscose or lyocell, offering biodegradability and breathability. True synthetic fibers, including polyester and nylon, are created from petrochemicals through polymerization, providing superior durability, elasticity, and resistance to moisture. The choice between regenerated and synthetic fibers depends on applications prioritizing environmental sustainability versus performance characteristics.

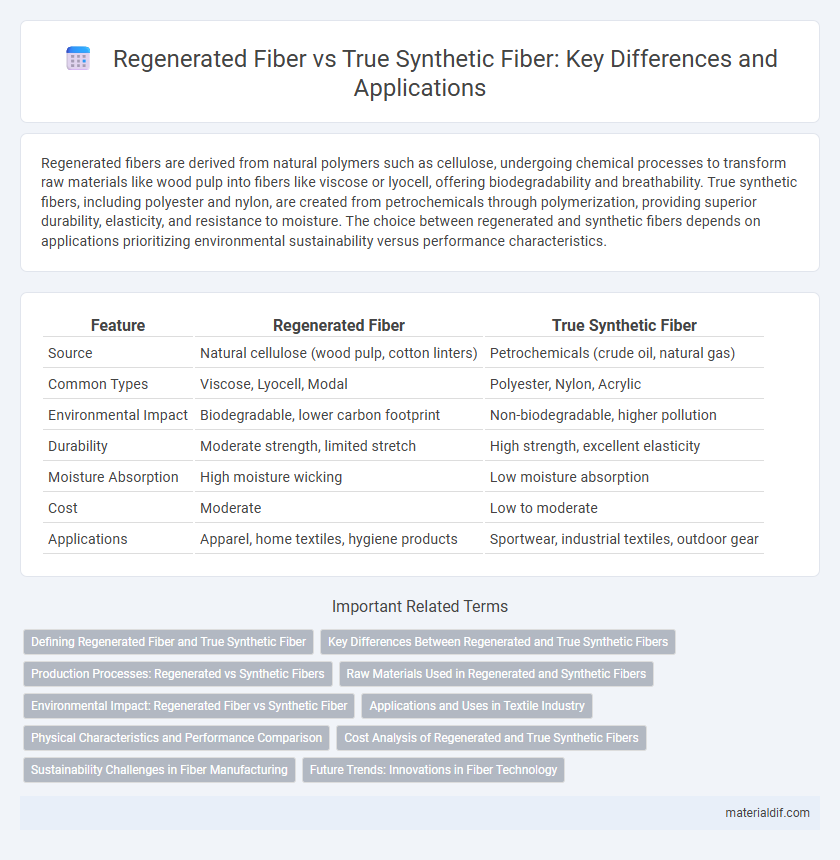

Table of Comparison

| Feature | Regenerated Fiber | True Synthetic Fiber |

|---|---|---|

| Source | Natural cellulose (wood pulp, cotton linters) | Petrochemicals (crude oil, natural gas) |

| Common Types | Viscose, Lyocell, Modal | Polyester, Nylon, Acrylic |

| Environmental Impact | Biodegradable, lower carbon footprint | Non-biodegradable, higher pollution |

| Durability | Moderate strength, limited stretch | High strength, excellent elasticity |

| Moisture Absorption | High moisture wicking | Low moisture absorption |

| Cost | Moderate | Low to moderate |

| Applications | Apparel, home textiles, hygiene products | Sportwear, industrial textiles, outdoor gear |

Defining Regenerated Fiber and True Synthetic Fiber

Regenerated fiber is produced by chemically processing natural polymers, such as cellulose from wood pulp, to create fibers like rayon or lyocell with properties similar to natural fibers. True synthetic fiber, including polyester, nylon, and acrylic, is made from petrochemical-derived polymers through polymerization, resulting in entirely man-made fibers with consistent quality and durability. Both fiber types are integral to the textile industry but differ fundamentally in their raw materials and manufacturing processes.

Key Differences Between Regenerated and True Synthetic Fibers

Regenerated fibers, such as rayon and lyocell, are derived from natural cellulose sources like wood pulp that undergo chemical processing to create fiber, while true synthetic fibers, including polyester and nylon, are produced entirely from petrochemicals through polymerization. Regenerated fibers retain some natural fiber properties, such as breathability and moisture absorption, whereas true synthetic fibers offer superior strength, durability, and resistance to environmental factors like UV exposure and chemicals. The environmental impact differs significantly, with regenerated fibers relying on renewable resources but involving intensive chemical treatments, in contrast to true synthetic fibers' dependence on non-renewable fossil fuels and challenges with biodegradability.

Production Processes: Regenerated vs Synthetic Fibers

Regenerated fibers are produced by chemically processing natural cellulose sources such as wood pulp or cotton linters, breaking them down into a viscous solution before re-spinning into fibers. True synthetic fibers are created through polymerization, synthesizing monomers derived from petrochemicals into long-chain polymers that are extruded into fibers. These distinct production processes impact environmental footprint, with regenerated fibers relying on renewable raw materials and synthetic fibers being fully petroleum-based.

Raw Materials Used in Regenerated and Synthetic Fibers

Regenerated fibers are primarily derived from natural polymers such as cellulose extracted from wood pulp, cotton linters, or bamboo, making them semi-synthetic due to the chemical processing involved in converting raw natural materials into fiber. True synthetic fibers rely exclusively on petrochemical sources like coal, petroleum, and natural gas, utilizing polymerization processes to produce fibers such as polyester, nylon, and acrylic. The raw material origin distinctly impacts the environmental footprint, biodegradability, and performance characteristics of regenerated versus synthetic fibers.

Environmental Impact: Regenerated Fiber vs Synthetic Fiber

Regenerated fibers, such as viscose and lyocell, are derived from natural cellulose sources and tend to have a lower environmental impact compared to true synthetic fibers like polyester and nylon, which are petroleum-based and non-biodegradable. The production of regenerated fibers involves chemical processing that can be managed sustainably with closed-loop systems, reducing water and air pollution. In contrast, synthetic fibers contribute significantly to microplastic pollution and rely heavily on fossil fuels, leading to higher carbon emissions and long-term ecological harm.

Applications and Uses in Textile Industry

Regenerated fibers such as viscose and lyocell, derived from natural cellulose sources, are extensively used in the textile industry for apparel, home textiles, and industrial fabrics due to their breathability, moisture absorption, and eco-friendliness. True synthetic fibers like polyester, nylon, and acrylic dominate applications requiring high durability, elasticity, and resistance to chemicals, making them ideal for sportswear, outerwear, and technical textiles. The choice between regenerated and synthetic fibers depends on performance requirements, environmental impact, and end-use functionality in fashion, upholstery, and specialized industrial sectors.

Physical Characteristics and Performance Comparison

Regenerated fibers, derived from natural cellulose sources, exhibit high moisture absorbency and a soft, breathable texture similar to natural fibers, whereas true synthetic fibers such as polyester and nylon possess superior tensile strength, elasticity, and resistance to abrasion and chemicals. Regenerated fibers tend to have moderate durability and lower resistance to environmental factors compared to synthetic fibers, which maintain colorfastness and shape retention under diverse conditions. Performance-wise, regenerated fibers offer better comfort for wearable textiles, while synthetic fibers dominate in industrial applications due to their enhanced mechanical properties and longevity.

Cost Analysis of Regenerated and True Synthetic Fibers

Regenerated fibers, derived from natural cellulose sources such as wood pulp, often exhibit lower raw material costs compared to true synthetic fibers like polyester and nylon, which are petroleum-based. Manufacturing expenses for regenerated fibers are influenced by chemical processing and environmental compliance, whereas synthetic fibers benefit from established mass production techniques that reduce unit costs. Despite higher energy consumption in synthetic fiber production, the consistent demand and scalability often result in competitive pricing versus the fluctuating costs of regenerated fiber production.

Sustainability Challenges in Fiber Manufacturing

Regenerated fibers, derived from natural polymers such as cellulose, offer a more biodegradable alternative to true synthetic fibers made from petrochemicals like polyester, which contribute significantly to microplastic pollution. However, the chemical processes involved in regenerating fibers often rely on toxic solvents and consume high energy, creating sustainability challenges despite using renewable raw materials. True synthetic fiber manufacturing typically entails lower water usage but results in higher greenhouse gas emissions and relies on non-renewable fossil fuels, complicating efforts to achieve circularity in the textile industry.

Future Trends: Innovations in Fiber Technology

Regenerated fibers, derived from natural polymers like cellulose, are evolving through advanced bioengineering techniques to enhance sustainability and performance, making them a preferred choice in eco-friendly textile applications. True synthetic fibers, predominantly made from petrochemicals such as polyester and nylon, are undergoing innovation with bio-based monomers and molecular engineering to improve biodegradability and reduce carbon footprints. Future trends emphasize the integration of nanotechnology, recycling methods, and smart fiber functionalities to create versatile, high-performance materials that align with circular economy principles.

Regenerated Fiber vs True Synthetic Fiber Infographic

materialdif.com

materialdif.com