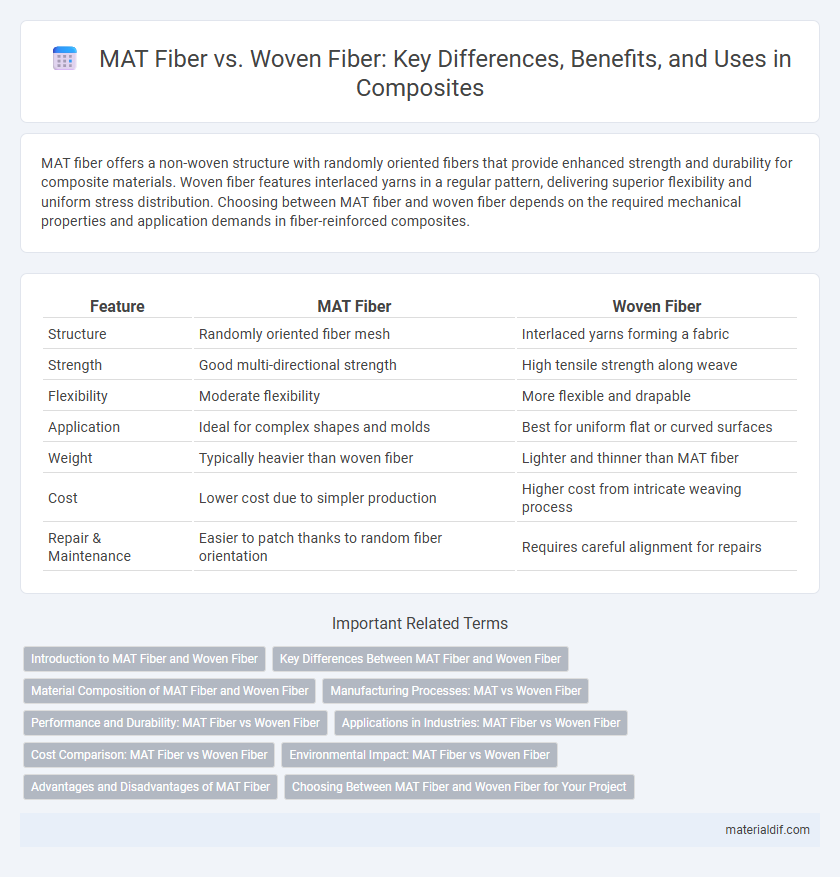

MAT fiber offers a non-woven structure with randomly oriented fibers that provide enhanced strength and durability for composite materials. Woven fiber features interlaced yarns in a regular pattern, delivering superior flexibility and uniform stress distribution. Choosing between MAT fiber and woven fiber depends on the required mechanical properties and application demands in fiber-reinforced composites.

Table of Comparison

| Feature | MAT Fiber | Woven Fiber |

|---|---|---|

| Structure | Randomly oriented fiber mesh | Interlaced yarns forming a fabric |

| Strength | Good multi-directional strength | High tensile strength along weave |

| Flexibility | Moderate flexibility | More flexible and drapable |

| Application | Ideal for complex shapes and molds | Best for uniform flat or curved surfaces |

| Weight | Typically heavier than woven fiber | Lighter and thinner than MAT fiber |

| Cost | Lower cost due to simpler production | Higher cost from intricate weaving process |

| Repair & Maintenance | Easier to patch thanks to random fiber orientation | Requires careful alignment for repairs |

Introduction to MAT Fiber and Woven Fiber

MAT fiber consists of randomly oriented chopped fibers that provide uniform strength and enhanced impact resistance across composite materials. Woven fiber features interlaced yarns arranged in specific patterns, offering superior dimensional stability and directional tensile strength. Both fiber types are critical in advanced composites, with MAT fiber enhancing isotropic properties and woven fiber optimizing load-bearing in targeted directions.

Key Differences Between MAT Fiber and Woven Fiber

MAT fiber consists of randomly oriented fibers bonded together, providing isotropic strength and ease of molding complex shapes in composite manufacturing. Woven fiber features fibers interlaced in a crisscross pattern, delivering superior tensile strength, dimensional stability, and enhanced resistance to fatigue and impact. The key differences lie in their mechanical properties, fabrication processes, and suitability for specific applications such as aerospace components or automotive panels.

Material Composition of MAT Fiber and Woven Fiber

MAT fiber typically consists of randomly oriented chopped glass fibers bonded with resin, resulting in a non-woven composite structure that enhances isotropic strength and ease of molding. Woven fiber is composed of continuous glass fiber yarns interlaced in specific patterns, such as plain weave or twill, offering superior directional strength and flexibility. The material composition differences influence mechanical properties, where MAT fibers provide uniform load distribution, and woven fibers deliver higher tensile strength along fiber directions.

Manufacturing Processes: MAT vs Woven Fiber

MAT fiber manufacturing involves randomly orienting short fibers into a mat and binding them with a resin binder through heat and pressure, creating a nonwoven fabric ideal for uniform thickness and high strength in composite parts. Woven fiber production weaves long fibers into a structured fabric using warp and weft threads, offering superior dimensional stability and directional strength, essential for load-bearing applications. The key difference lies in MAT's random fiber orientation suited for complex shapes versus woven fiber's organized pattern optimized for mechanical performance and durability.

Performance and Durability: MAT Fiber vs Woven Fiber

MAT fiber offers superior impact resistance and energy absorption due to its random orientation of short fibers, enhancing overall mechanical performance in dynamic applications. Woven fiber provides higher tensile strength and dimensional stability through its interlaced continuous yarn structure, making it ideal for load-bearing components requiring precise structural integrity. Durability in MAT fiber is generally lower under repeated cyclic loading compared to woven fiber, which exhibits better fatigue resistance and long-term performance in harsh environments.

Applications in Industries: MAT Fiber vs Woven Fiber

MAT fiber offers superior impact resistance and molding ease, making it ideal for automotive body panels and marine hulls, where rapid production and complex shapes are essential. Woven fiber provides enhanced tensile strength and dimensional stability, preferred in aerospace and sporting goods applications requiring high performance and durability under stress. Both fibers are selected based on industry-specific demands for strength, flexibility, and manufacturing efficiency.

Cost Comparison: MAT Fiber vs Woven Fiber

MAT fiber typically offers lower material costs due to its random fiber orientation, which reduces manufacturing complexity compared to woven fiber. Woven fiber involves higher production expenses because of its precise interlacing process, contributing to increased labor and tooling costs. Overall, MAT fiber is more cost-effective for large-scale applications where structural customization is less critical, while woven fiber suits projects demanding superior mechanical properties despite higher investment.

Environmental Impact: MAT Fiber vs Woven Fiber

MAT fiber generally generates less environmental waste due to its shorter production cycle and lower raw material consumption compared to woven fiber, which requires extensive water and energy for weaving processes. The non-woven manufacturing method of MAT fiber reduces carbon emissions and chemical use, enhancing its sustainability profile. Woven fiber, while durable, involves higher resource inputs and greater ecological footprint, making MAT fiber a more eco-friendly option in composite materials.

Advantages and Disadvantages of MAT Fiber

MAT fiber offers advantages such as easier handling and faster installation due to its pre-arranged fiber orientation, leading to improved consistency and reduced labor costs in composite manufacturing. However, MAT fiber typically exhibits lower mechanical strength and stiffness compared to woven fiber, which can compromise structural performance in high-stress applications. Its relatively higher resin content also results in increased weight and potential for reduced impact resistance compared to woven fiber alternatives.

Choosing Between MAT Fiber and Woven Fiber for Your Project

MAT fiber offers excellent conformability and uniform strength distribution, making it ideal for complex shapes and high-impact applications. Woven fiber provides superior dimensional stability and directional strength, which benefits projects requiring precise load management and enhanced durability. Selecting between MAT and woven fiber depends on the project's structural demands, surface finish requirements, and performance criteria.

MAT Fiber vs Woven Fiber Infographic

materialdif.com

materialdif.com