Spun fiber and continuous fiber differ primarily in their structural form and applications; spun fibers are short, staple fibers twisted together to form yarn, offering softness and flexibility, while continuous fibers are long, continuous strands that provide superior strength and durability. Continuous fibers are used in high-performance textiles and composites where tensile strength is critical, whereas spun fibers are common in everyday fabrics due to their comfort and breathability. Choosing between spun and continuous fiber depends on the desired balance of strength, texture, and application requirements in fiber production.

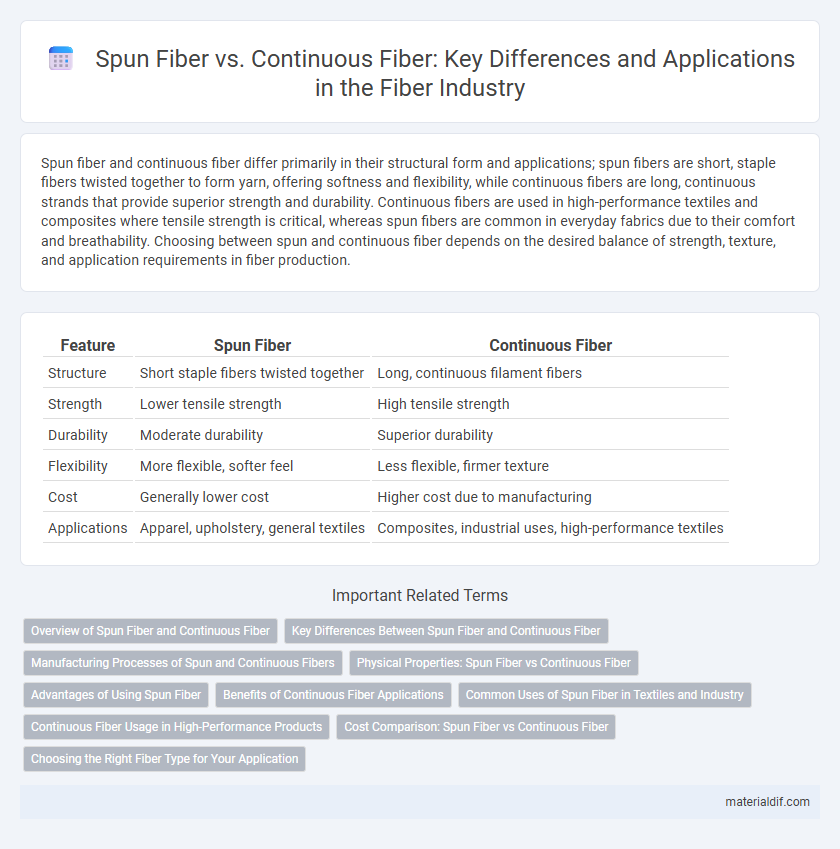

Table of Comparison

| Feature | Spun Fiber | Continuous Fiber |

|---|---|---|

| Structure | Short staple fibers twisted together | Long, continuous filament fibers |

| Strength | Lower tensile strength | High tensile strength |

| Durability | Moderate durability | Superior durability |

| Flexibility | More flexible, softer feel | Less flexible, firmer texture |

| Cost | Generally lower cost | Higher cost due to manufacturing |

| Applications | Apparel, upholstery, general textiles | Composites, industrial uses, high-performance textiles |

Overview of Spun Fiber and Continuous Fiber

Spun fiber consists of short staple fibers twisted together to form yarn, offering a soft texture and excellent insulation properties. Continuous fiber, also known as filament fiber, features long, unbroken strands that provide superior strength, durability, and smoothness. Both types are essential in textile applications, with spun fibers commonly used in cozy garments and continuous fibers favored for high-performance fabrics.

Key Differences Between Spun Fiber and Continuous Fiber

Spun fiber consists of short staple fibers twisted together, resulting in a textured surface and a soft, fuzzy feel, ideal for warmth and insulation in textiles. Continuous fiber, also known as filament fiber, is composed of long, continuous strands that produce smoother, stronger, and more durable fabrics, commonly used in performance and industrial applications. Key differences lie in fiber length, texture, strength, and end-use, with spun fibers offering comfort and breathability, while continuous fibers excel in tensile strength and uniformity.

Manufacturing Processes of Spun and Continuous Fibers

Spun fiber manufacturing involves twisting short staple fibers together through carding, drawing, and spinning processes to create yarns with enhanced strength and flexibility. Continuous fiber production relies on extrusion techniques where polymer melts or solutions are drawn through spinnerets, forming long, continuous filaments aligned for superior tensile properties. These distinct manufacturing processes influence the fiber's structural uniformity, mechanical performance, and suitability for various textile applications.

Physical Properties: Spun Fiber vs Continuous Fiber

Spun fibers exhibit shorter lengths and irregular surfaces, resulting in a fuzzy texture and greater softness, while continuous fibers are long, smooth, and uniform, providing higher tensile strength and durability. The physical properties of continuous fibers include enhanced resistance to abrasion and better load distribution compared to the weaker inter-fiber bonds in spun fibers. Consequently, continuous fibers are preferred in applications requiring superior mechanical performance and structural integrity.

Advantages of Using Spun Fiber

Spun fiber offers superior softness and warmth, making it ideal for comfortable textiles and insulation materials. Its short staple length enhances fabric durability and reduces pilling compared to continuous fiber. The versatility of spun fiber allows for easier blending with other materials, optimizing performance in diverse applications.

Benefits of Continuous Fiber Applications

Continuous fiber offers superior mechanical strength and enhanced durability compared to spun fiber, making it ideal for high-performance composite materials in aerospace and automotive industries. Its uniform length and consistent alignment enable improved load distribution and greater tensile strength, resulting in lightweight structural components with increased fatigue resistance. Continuous fiber applications also facilitate efficient automation in manufacturing processes, reducing production costs and enabling large-scale deployment of advanced fiber-reinforced polymers.

Common Uses of Spun Fiber in Textiles and Industry

Spun fiber is commonly used in the production of cotton shirts, wool sweaters, and home textiles due to its soft texture and breathability. In the industrial sector, spun fibers are ideal for creating durable nonwoven fabrics used in filters, insulation, and automotive interiors. The versatility of spun fiber makes it essential for applications requiring cushioning, softness, and flexibility.

Continuous Fiber Usage in High-Performance Products

Continuous fiber is extensively used in high-performance products due to its superior tensile strength and uniformity compared to spun fiber. Its continuous filament structure enhances load distribution and impact resistance, making it ideal for aerospace, automotive, and sporting goods applications. The consistent diameter and length of continuous fibers enable advanced composite manufacturing techniques like filament winding and pultrusion, optimizing material performance and durability.

Cost Comparison: Spun Fiber vs Continuous Fiber

Spun fiber typically incurs lower upfront costs due to simpler manufacturing processes and less expensive raw materials compared to continuous fiber, which requires more advanced production techniques and higher-grade inputs. Continuous fiber, while more costly initially, offers superior strength-to-weight ratio and durability that can reduce long-term expenses in applications like aerospace and automotive industries. The cost efficiency of spun fiber versus continuous fiber ultimately depends on the specific performance requirements and lifespan considerations of the end product.

Choosing the Right Fiber Type for Your Application

Spun fiber, made from short staple fibers twisted together, offers enhanced softness and insulation, making it ideal for apparel and home textiles. Continuous fiber, consisting of long filaments, provides superior strength and uniformity, suitable for industrial applications like composites and technical fabrics. Selecting the right fiber depends on specific performance requirements such as durability, flexibility, and texture to optimize product functionality and cost-efficiency.

Spun Fiber vs Continuous Fiber Infographic

materialdif.com

materialdif.com