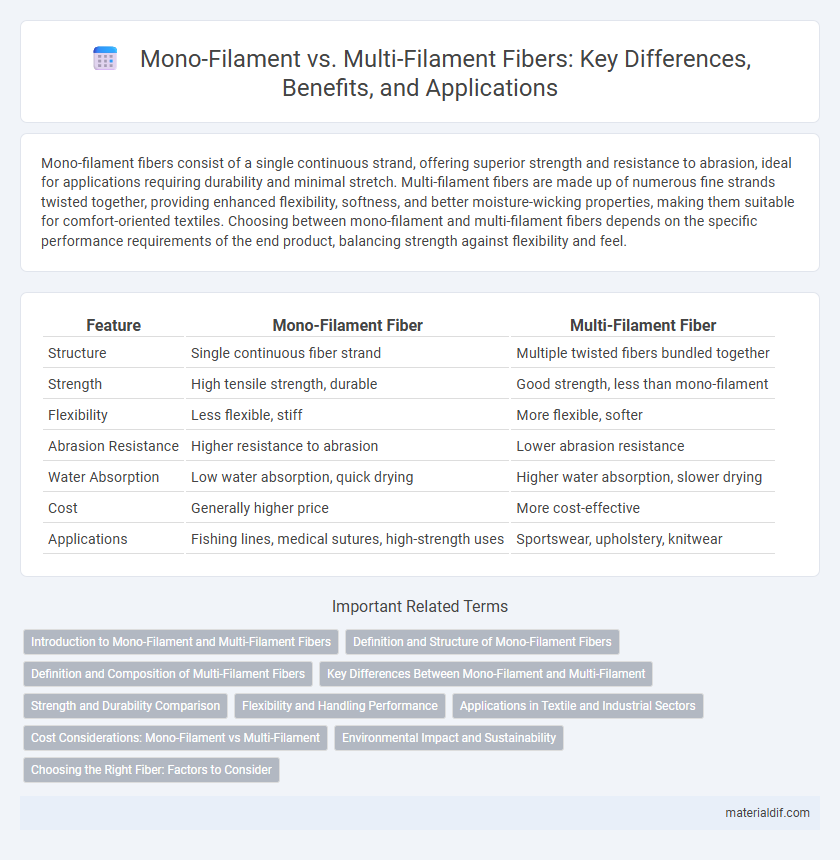

Mono-filament fibers consist of a single continuous strand, offering superior strength and resistance to abrasion, ideal for applications requiring durability and minimal stretch. Multi-filament fibers are made up of numerous fine strands twisted together, providing enhanced flexibility, softness, and better moisture-wicking properties, making them suitable for comfort-oriented textiles. Choosing between mono-filament and multi-filament fibers depends on the specific performance requirements of the end product, balancing strength against flexibility and feel.

Table of Comparison

| Feature | Mono-Filament Fiber | Multi-Filament Fiber |

|---|---|---|

| Structure | Single continuous fiber strand | Multiple twisted fibers bundled together |

| Strength | High tensile strength, durable | Good strength, less than mono-filament |

| Flexibility | Less flexible, stiff | More flexible, softer |

| Abrasion Resistance | Higher resistance to abrasion | Lower abrasion resistance |

| Water Absorption | Low water absorption, quick drying | Higher water absorption, slower drying |

| Cost | Generally higher price | More cost-effective |

| Applications | Fishing lines, medical sutures, high-strength uses | Sportswear, upholstery, knitwear |

Introduction to Mono-Filament and Multi-Filament Fibers

Mono-filament fibers consist of a single, continuous strand of material, providing high tensile strength and smooth texture ideal for applications requiring durability and abrasion resistance. Multi-filament fibers are composed of multiple finer filaments twisted or bonded together, offering enhanced flexibility, softness, and increased surface area for improved moisture wicking and comfort. The choice between mono-filament and multi-filament fibers depends on specific performance requirements such as strength, flexibility, and tactile properties.

Definition and Structure of Mono-Filament Fibers

Mono-filament fibers consist of a single, continuous strand of material, offering a smooth and uniform structure that enhances durability and abrasion resistance. These fibers are typically made from polymers like nylon, polyester, or polypropylene, forming a solid core without internal splits or bundles. The simplicity of the mono-filament structure allows for minimal water absorption and high tensile strength, making them ideal for applications requiring resistance to wear and tear.

Definition and Composition of Multi-Filament Fibers

Multi-filament fibers consist of numerous fine filaments twisted or bonded together to form a single strand, providing enhanced strength and flexibility compared to mono-filament fibers, which are single continuous fibers. These fibers are typically made from synthetic materials such as nylon, polyester, or polypropylene, allowing customization in durability, texture, and performance for various textile applications. The intertwined structure of multi-filament fibers improves abrasion resistance and breathability, making them suitable for high-performance fabrics in sportswear and industrial uses.

Key Differences Between Mono-Filament and Multi-Filament

Mono-filament fibers consist of a single, continuous strand that offers high tensile strength, low water absorption, and excellent durability, making them ideal for outdoor applications. Multi-filament fibers are composed of multiple finer strands twisted together, providing superior flexibility, softness, and enhanced breathability, commonly used in activewear and comfort-focused textiles. The key differences lie in their structural composition, performance characteristics, and suitability for specific end-use purposes.

Strength and Durability Comparison

Mono-filament fibers offer high tensile strength due to their single continuous strand structure, providing superior resistance to breakage under tension. Multi-filament fibers consist of multiple intertwined strands, enhancing flexibility and abrasion resistance, which contributes to greater overall durability in dynamic applications. Choosing between mono-filament and multi-filament depends on the specific strength requirements and environmental conditions of the intended use.

Flexibility and Handling Performance

Mono-filament fibers offer superior flexibility, making them ideal for applications requiring smooth bending and minimal stiffness. Multi-filament fibers provide enhanced handling performance due to their braided or twisted structure, which improves grip and reduces slippage. The choice between mono-filament and multi-filament depends on the balance needed between flexibility and tactile control in specific fiber use cases.

Applications in Textile and Industrial Sectors

Mono-filament fibers offer superior strength and abrasion resistance, making them ideal for industrial applications such as conveyor belts, fishing lines, and reinforcement in composites. Multi-filament fibers provide greater flexibility and softness, preferred in textile sectors for clothing, upholstery, and performance fabrics. The choice between mono-filament and multi-filament depends on specific requirements for durability, texture, and elasticity in diverse industrial and textile uses.

Cost Considerations: Mono-Filament vs Multi-Filament

Mono-filament fiber typically incurs higher manufacturing costs due to its single, continuous strand requiring precise extrusion processes, whereas multi-filament fibers benefit from bulk production of multiple fine strands twisted together, reducing overall expenses. In applications demanding durability and elasticity, multi-filament fibers offer better cost-efficiency by balancing performance with lower material costs. Choosing mono-filament fibers often involves higher upfront investment but can justify the expense in specialized uses requiring superior tensile strength and abrasion resistance.

Environmental Impact and Sustainability

Mono-filament fibers generate less microplastic pollution due to their single continuous strand structure, reducing environmental contamination in marine and terrestrial ecosystems. Multi-filament fibers, composed of multiple fine strands, tend to shed more microfibers during washing, contributing significantly to plastic pollution in water bodies. Choosing mono-filament fiber products enhances sustainability by minimizing fiber loss, improving durability, and reducing resource consumption in textile manufacturing.

Choosing the Right Fiber: Factors to Consider

Choosing the right fiber between mono-filament and multi-filament depends on application requirements such as strength, flexibility, and abrasion resistance. Mono-filament fibers offer higher tensile strength and durability, making them suitable for heavy-duty tasks, while multi-filament fibers provide enhanced flexibility and softness, ideal for sensitive or lightweight applications. Consider factors like load capacity, environmental exposure, and cost-efficiency to ensure optimal fiber performance.

Mono-Filament vs Multi-Filament Infographic

materialdif.com

materialdif.com