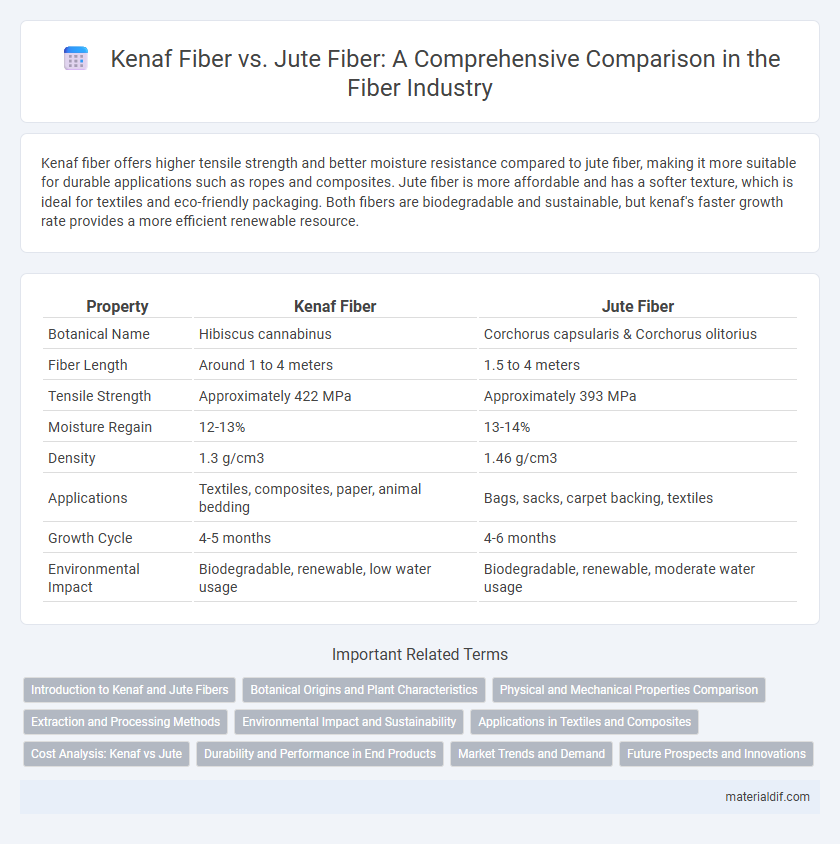

Kenaf fiber offers higher tensile strength and better moisture resistance compared to jute fiber, making it more suitable for durable applications such as ropes and composites. Jute fiber is more affordable and has a softer texture, which is ideal for textiles and eco-friendly packaging. Both fibers are biodegradable and sustainable, but kenaf's faster growth rate provides a more efficient renewable resource.

Table of Comparison

| Property | Kenaf Fiber | Jute Fiber |

|---|---|---|

| Botanical Name | Hibiscus cannabinus | Corchorus capsularis & Corchorus olitorius |

| Fiber Length | Around 1 to 4 meters | 1.5 to 4 meters |

| Tensile Strength | Approximately 422 MPa | Approximately 393 MPa |

| Moisture Regain | 12-13% | 13-14% |

| Density | 1.3 g/cm3 | 1.46 g/cm3 |

| Applications | Textiles, composites, paper, animal bedding | Bags, sacks, carpet backing, textiles |

| Growth Cycle | 4-5 months | 4-6 months |

| Environmental Impact | Biodegradable, renewable, low water usage | Biodegradable, renewable, moderate water usage |

Introduction to Kenaf and Jute Fibers

Kenaf fiber, derived from the Hibiscus cannabinus plant, is a fast-growing, sustainable natural fiber known for its strength and versatility in composites and textiles. Jute fiber, extracted from the Corchorus species, is one of the most affordable and widely used bast fibers globally, prized for its coarse texture and biodegradability. Both fibers offer eco-friendly alternatives to synthetic materials, with kenaf favored for industrial applications and jute commonly used in packaging and home furnishings.

Botanical Origins and Plant Characteristics

Kenaf fiber is derived from Hibiscus cannabinus, a fast-growing annual plant with a woody stalk, while jute fiber comes from Corchorus species, primarily Corchorus olitorius and Corchorus capsularis, which are tall, herbaceous plants. Kenaf typically reaches heights of 3 to 4.5 meters and has broader leaves compared to the thinner, more fibrous stems of jute plants that grow up to 4 meters. Both fibers are bast fibers extracted from the phloem or bark of their respective plants but differ in fiber length, strength, and cellulose content due to their distinct botanical origins.

Physical and Mechanical Properties Comparison

Kenaf fiber exhibits higher tensile strength and greater elongation at break compared to jute fiber, making it more durable for industrial applications. Its density is lower, providing a better strength-to-weight ratio, while jute fiber shows superior moisture absorption and flexibility due to its lignin and cellulose composition. Kenaf also has enhanced abrasion resistance and stiffness, making it ideal for composites and reinforced materials in automotive and construction sectors.

Extraction and Processing Methods

Kenaf fiber extraction primarily involves water retting, where the stems are soaked to loosen the fibers, followed by mechanical decortication to separate the bast fibers from the core. In contrast, jute fiber extraction relies heavily on traditional water retting, with microbial action breaking down the pectin binding the fibers, and manual stripping methods to obtain the long, shiny fibers. Both fibers require drying and combing processes, but kenaf's mechanical decortication offers a faster and more industrial-friendly approach compared to the labor-intensive jute retting and manual extraction.

Environmental Impact and Sustainability

Kenaf fiber exhibits a lower environmental impact than jute fiber due to its faster growth rate, requiring less water and pesticides, which reduces resource consumption and soil degradation. Kenaf plants absorb higher levels of CO2 during cultivation, contributing to better carbon sequestration and climate change mitigation. Both fibers are biodegradable and renewable, but kenaf's efficient land use and minimal chemical input make it a more sustainable option in eco-friendly textile and composite industries.

Applications in Textiles and Composites

Kenaf fiber exhibits superior tensile strength and durability compared to jute fiber, making it highly suitable for industrial textiles, upholstery, and automotive composites where reinforcement is critical. Jute fiber's softness and affordability favor its widespread use in lighter textile products such as bags, rugs, and home furnishings, while its coarse texture limits heavy-duty composite applications. Both fibers are biodegradable and eco-friendly alternatives in sustainable materials, but kenaf's enhanced mechanical properties drive its preference in high-performance composites.

Cost Analysis: Kenaf vs Jute

Kenaf fiber typically costs more than jute fiber due to higher cultivation and processing expenses, driven by Kenaf's faster growth cycle and superior fiber strength. Jute remains more economical, favored in large-scale production for its lower input costs and established supply chains. While Kenaf offers durability and environmental benefits, jute's cost-effectiveness makes it a preferred choice for budget-conscious applications.

Durability and Performance in End Products

Kenaf fiber exhibits higher tensile strength and better resistance to wear compared to jute fiber, making it more durable for long-lasting end products such as composites and ropes. Jute fiber, while less robust, offers superior flexibility and moisture absorbency, suitable for textiles and packaging materials. Performance in applications requiring durability and structural integrity favors kenaf fiber due to its enhanced fiber length and cellulose content.

Market Trends and Demand

Kenaf fiber is experiencing increased demand due to its eco-friendly properties and versatility in applications like bioplastics, composites, and paper products, driving growth in sustainable material markets. Jute fiber maintains steady demand, primarily fueled by its traditional use in packaging, textiles, and geotextiles, with emerging interest in blending with synthetic fibers for enhanced durability. Market trends indicate a growing preference for kenaf in high-value industries, while jute's affordability sustains its dominance in bulk commodity markets.

Future Prospects and Innovations

Kenaf fiber exhibits significant future prospects due to its rapid growth rate, high tensile strength, and eco-friendly properties, making it ideal for sustainable composites and biodegradable materials in automotive and construction industries. Innovations in enzymatic retting and nanocellulose extraction from kenaf fibers are enhancing fiber quality and expanding its applications in advanced textiles and bio-based packaging. Jute fiber remains valuable with ongoing improvements in fiber processing and integration into smart textiles, but kenaf's superior mechanical properties and versatility position it as a leading candidate for next-generation sustainable material solutions.

Kenaf Fiber vs Jute Fiber Infographic

materialdif.com

materialdif.com