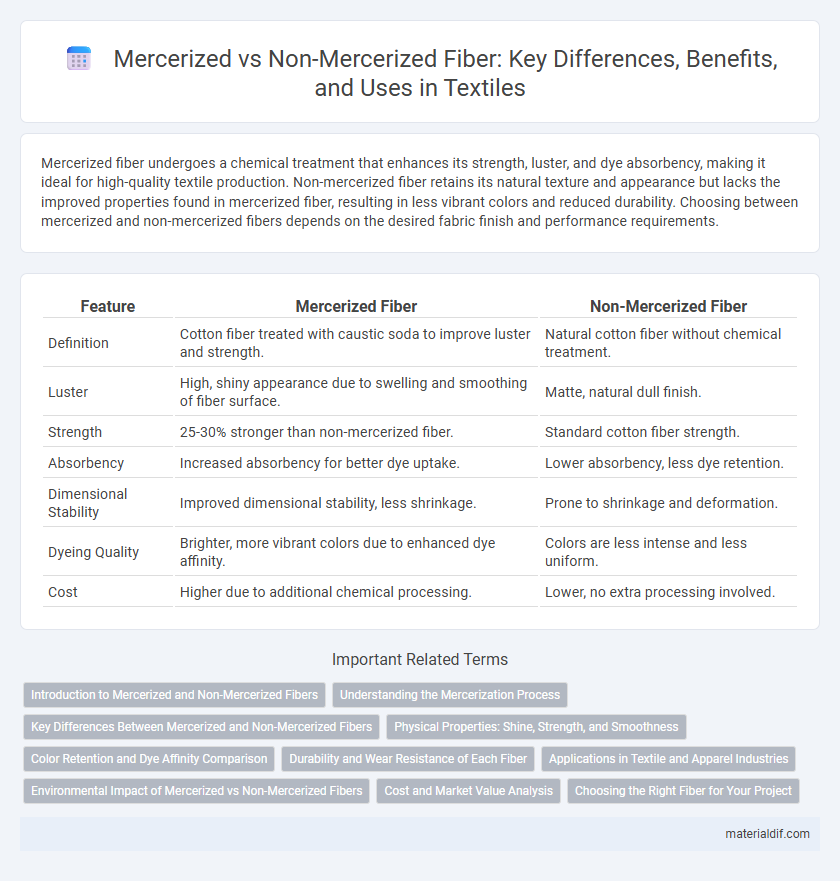

Mercerized fiber undergoes a chemical treatment that enhances its strength, luster, and dye absorbency, making it ideal for high-quality textile production. Non-mercerized fiber retains its natural texture and appearance but lacks the improved properties found in mercerized fiber, resulting in less vibrant colors and reduced durability. Choosing between mercerized and non-mercerized fibers depends on the desired fabric finish and performance requirements.

Table of Comparison

| Feature | Mercerized Fiber | Non-Mercerized Fiber |

|---|---|---|

| Definition | Cotton fiber treated with caustic soda to improve luster and strength. | Natural cotton fiber without chemical treatment. |

| Luster | High, shiny appearance due to swelling and smoothing of fiber surface. | Matte, natural dull finish. |

| Strength | 25-30% stronger than non-mercerized fiber. | Standard cotton fiber strength. |

| Absorbency | Increased absorbency for better dye uptake. | Lower absorbency, less dye retention. |

| Dimensional Stability | Improved dimensional stability, less shrinkage. | Prone to shrinkage and deformation. |

| Dyeing Quality | Brighter, more vibrant colors due to enhanced dye affinity. | Colors are less intense and less uniform. |

| Cost | Higher due to additional chemical processing. | Lower, no extra processing involved. |

Introduction to Mercerized and Non-Mercerized Fibers

Mercerized fiber undergoes a chemical treatment with sodium hydroxide, enhancing its strength, luster, and dye affinity compared to non-mercerized fiber. Non-mercerized fiber retains its natural texture and absorbency but lacks the enhanced durability and sheen of mercerized fiber. This difference in processing results in mercerized fiber being preferred for high-quality textiles that require vibrant colors and smooth finishes.

Understanding the Mercerization Process

Mercerization is a chemical treatment applied to cotton fibers involving the immersion in a concentrated sodium hydroxide solution, which enhances fiber strength, luster, and dye affinity. Mercerized fibers exhibit improved dimensional stability and sheen compared to non-mercerized fibers, which retain their natural matte finish and lower dye uptake. The process also alters the fiber cross-section from kidney-shaped to round, optimizing surface area and contributing to superior fabric quality in textiles.

Key Differences Between Mercerized and Non-Mercerized Fibers

Mercerized fiber undergoes a chemical treatment with caustic soda, enhancing its strength, luster, and dye affinity compared to non-mercerized fiber, which retains its natural texture and lower tensile strength. Mercerization increases fiber smoothness and reduces shrinkage, making fabrics more durable and vibrant in color. Non-mercerized fibers are generally softer and more breathable but lack the enhanced sheen and durability provided by the mercerizing process.

Physical Properties: Shine, Strength, and Smoothness

Mercerized fiber exhibits enhanced physical properties such as increased shine, superior strength, and a smoother texture compared to non-mercerized fiber. The mercerization process alters the fiber's crystalline structure, resulting in improved luster and tensile strength, making it more durable and aesthetically appealing. Non-mercerized fibers typically have a duller appearance, lower tensile strength, and a rougher surface texture, limiting their use in high-quality textile applications.

Color Retention and Dye Affinity Comparison

Mercerized fiber exhibits superior color retention due to the increased surface smoothness and enhanced crystallinity achieved through the mercerization process, allowing dyes to penetrate more deeply and adhere more effectively. Non-mercerized fiber, with its rougher cellulose surface, tends to have lower dye affinity, resulting in colors that fade more quickly under washing and exposure to light. Studies show mercerized fibers maintain vibrancy and resist fading significantly better, making them ideal for high-quality textile applications requiring long-lasting color.

Durability and Wear Resistance of Each Fiber

Mercerized fiber exhibits enhanced durability and superior wear resistance due to the chemical treatment that strengthens the cellulose structure, resulting in a smoother and more resilient surface. Non-mercerized fiber tends to have lower abrasion resistance and durability, as it retains the natural fiber structure, making it more prone to fraying and wear over time. The mercerization process significantly improves fiber longevity, making mercerized fibers ideal for high-performance textile applications.

Applications in Textile and Apparel Industries

Mercerized fiber enhances luster, dye affinity, and strength, making it ideal for high-end textiles and apparel such as luxury shirting and fine knitwear. Non-mercerized fiber, with its natural texture and absorbency, is preferred for casual wear, denim, and home textiles where softness and breathability are prioritized. Textile manufacturers select mercerized fibers for premium products requiring durability and vibrant colors, while non-mercerized fibers serve cost-effective and comfort-focused applications.

Environmental Impact of Mercerized vs Non-Mercerized Fibers

Mercerized fiber undergoes a chemical treatment involving sodium hydroxide, which enhances luster and dye absorption but introduces environmental concerns due to the use of caustic chemicals and energy-intensive processing. Non-mercerized fiber, lacking this chemical treatment, generally has a lower environmental footprint with less water and chemical consumption, making it more sustainable. However, advancements in eco-friendly mercerization methods aim to reduce waste and pollution, narrowing the gap between these two fiber types in environmental impact.

Cost and Market Value Analysis

Mercerized fiber typically incurs higher production costs due to the additional chemical treatment process that enhances fiber strength, luster, and dye affinity, leading to increased market value in premium textile applications. Non-mercerized fiber, while more cost-effective and widely available, often exhibits lower tensile strength and less vibrant color retention, positioning it in budget-conscious segments. Market trends indicate growing consumer preference for mercerized fibers in high-end fashion and technical fabrics, driving demand and price premiums despite the increased manufacturing expenses.

Choosing the Right Fiber for Your Project

Mercerized fiber offers enhanced strength, luster, and dye absorption compared to non-mercerized fiber, making it ideal for premium textile projects requiring vibrant colors and durability. Non-mercerized fiber retains a softer texture and natural appearance, suitable for casual wear or applications where a matte finish is preferred. Choose mercerized fiber for high-quality, long-lasting fabrics, while non-mercerized fiber is best for projects emphasizing comfort and a rustic aesthetic.

Mercerized Fiber vs Non-Mercerized Fiber Infographic

materialdif.com

materialdif.com