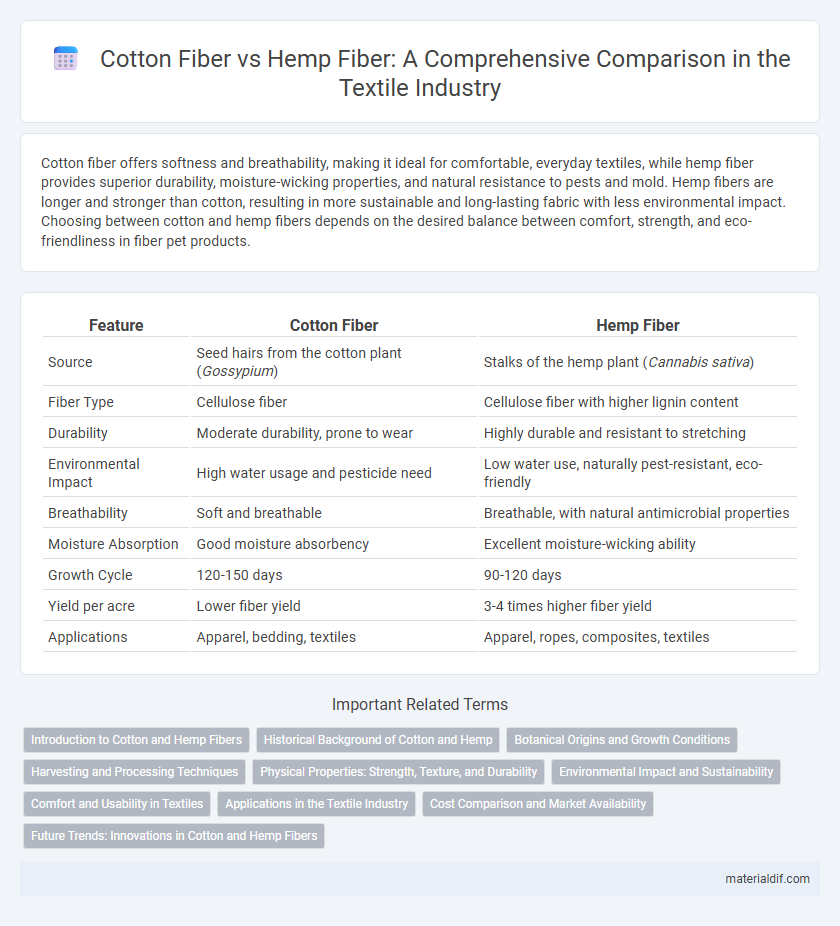

Cotton fiber offers softness and breathability, making it ideal for comfortable, everyday textiles, while hemp fiber provides superior durability, moisture-wicking properties, and natural resistance to pests and mold. Hemp fibers are longer and stronger than cotton, resulting in more sustainable and long-lasting fabric with less environmental impact. Choosing between cotton and hemp fibers depends on the desired balance between comfort, strength, and eco-friendliness in fiber pet products.

Table of Comparison

| Feature | Cotton Fiber | Hemp Fiber |

|---|---|---|

| Source | Seed hairs from the cotton plant (Gossypium) | Stalks of the hemp plant (Cannabis sativa) |

| Fiber Type | Cellulose fiber | Cellulose fiber with higher lignin content |

| Durability | Moderate durability, prone to wear | Highly durable and resistant to stretching |

| Environmental Impact | High water usage and pesticide need | Low water use, naturally pest-resistant, eco-friendly |

| Breathability | Soft and breathable | Breathable, with natural antimicrobial properties |

| Moisture Absorption | Good moisture absorbency | Excellent moisture-wicking ability |

| Growth Cycle | 120-150 days | 90-120 days |

| Yield per acre | Lower fiber yield | 3-4 times higher fiber yield |

| Applications | Apparel, bedding, textiles | Apparel, ropes, composites, textiles |

Introduction to Cotton and Hemp Fibers

Cotton fiber, derived from the seed hairs of the Gossypium plant, is widely valued for its softness, breathability, and moisture absorption, making it a popular choice in textiles. Hemp fiber, extracted from the stalks of the Cannabis sativa plant, is known for its exceptional strength, durability, and resistance to pests and mold, offering a sustainable alternative to conventional fibers. Both fibers have unique properties that influence their applications in fashion, home textiles, and industrial uses.

Historical Background of Cotton and Hemp

Cotton fiber has been cultivated for over 7,000 years, originating in regions such as the Indus Valley and Ancient Egypt, where it became a staple textile material due to its softness and breathability. Hemp fiber, one of the earliest domesticated fibers dating back more than 10,000 years in Central Asia, was historically valued for its durability and strength, commonly used in ropes, sails, and coarse fabrics. The widespread industrialization of cotton during the 18th and 19th centuries, driven by the invention of the cotton gin, contrasted with hemp's decline due to legal restrictions despite its long-standing global agricultural significance.

Botanical Origins and Growth Conditions

Cotton fiber originates from the seed hairs of the Gossypium plant, thriving in warm climates with long frost-free periods and moderate rainfall between 600-1200mm annually. Hemp fiber comes from the stalks of the Cannabis sativa plant, favoring temperate regions with well-drained loamy soil and requiring about 500-700mm of rain for optimal growth. Unlike cotton, hemp has a rapid growth cycle of 90-120 days and can regenerate soil quality through phytoremediation, making it more sustainable in various agricultural conditions.

Harvesting and Processing Techniques

Hemp fiber harvesting involves mechanical decortication that separates bast fibers from the core, resulting in less water usage and chemical treatment compared to cotton, which relies heavily on labor-intensive picking and extensive chemical processing to remove seeds and lint. The retting process in hemp cultivation, utilizing dew or water retting, enhances fiber quality while minimizing environmental impact, whereas cotton undergoes ginning to extract fibers from seeds, often involving synthetic chemicals that affect soil health. These distinct harvesting and processing techniques contribute to hemp's sustainability advantages and influence fiber strength, durability, and industrial application versatility.

Physical Properties: Strength, Texture, and Durability

Hemp fiber surpasses cotton fiber in strength due to its long and coarse strands, resulting in greater tensile resilience and durability suitable for heavy-duty applications. Cotton fiber, being soft and fine, offers a smoother texture that enhances comfort but compromises durability and tensile strength compared to hemp. The coarse texture of hemp also contributes to better resistance to wear and environmental factors, making it ideal for eco-friendly textiles demanding longevity.

Environmental Impact and Sustainability

Cotton fiber cultivation requires significant amounts of water and pesticides, contributing to soil degradation and high environmental footprints. In contrast, hemp fiber grows rapidly with minimal water and chemical inputs, promoting soil health and carbon sequestration. Hemp's sustainability advantages make it a more eco-friendly alternative to traditional cotton fiber.

Comfort and Usability in Textiles

Cotton fiber offers superior softness and breathability, making it ideal for comfortable everyday clothing and sensitive skin applications. Hemp fiber provides greater durability and moisture-wicking properties, enhancing usability in rugged textiles and eco-friendly fabrics. Combining cotton's softness with hemp's strength produces versatile textiles that balance comfort and long-lasting performance.

Applications in the Textile Industry

Cotton fiber dominates the textile industry due to its softness, breathability, and versatility in producing garments, home textiles, and industrial fabrics. Hemp fiber offers superior durability, antimicrobial properties, and sustainability, making it ideal for eco-friendly clothing, upholstery, and technical textiles. The integration of hemp fiber in blends with cotton enhances fabric strength and longevity while reducing environmental impact in textile manufacturing.

Cost Comparison and Market Availability

Cotton fiber generally costs more than hemp fiber due to its widespread demand and established supply chains, while hemp fiber offers a cost-effective alternative with lower cultivation expenses and higher yields per acre. Market availability of cotton fiber remains dominant globally, supported by extensive processing infrastructure, whereas hemp fiber availability is expanding rapidly as regulations ease and consumer interest in sustainable materials grows. Hemp fiber's increasing market presence and competitive pricing position it as a viable substitute in textile and industrial applications compared to traditional cotton fiber.

Future Trends: Innovations in Cotton and Hemp Fibers

Innovations in cotton fiber focus on sustainable farming techniques and genetically engineered crops to increase yield and reduce water consumption, while hemp fiber developments emphasize eco-friendly processing methods and enhanced fiber strength for industrial applications. Emerging technologies in cotton, such as bioengineered pest resistance, aim to lower chemical use, whereas hemp benefits from advances in mechanical decortication to improve fiber extraction efficiency. The growing demand for biodegradable and durable textiles drives research into hybrid materials combining cotton and hemp fibers to optimize performance and environmental impact.

Cotton Fiber vs Hemp Fiber Infographic

materialdif.com

materialdif.com