S-Glass fiber offers superior tensile strength and thermal resistance compared to E-Glass fiber, making it ideal for high-performance applications requiring enhanced durability. E-Glass fiber is more cost-effective and widely used in general-purpose composites due to its good mechanical properties and electrical insulation. Choosing between S-Glass and E-Glass depends on the balance between performance demands and budget constraints.

Table of Comparison

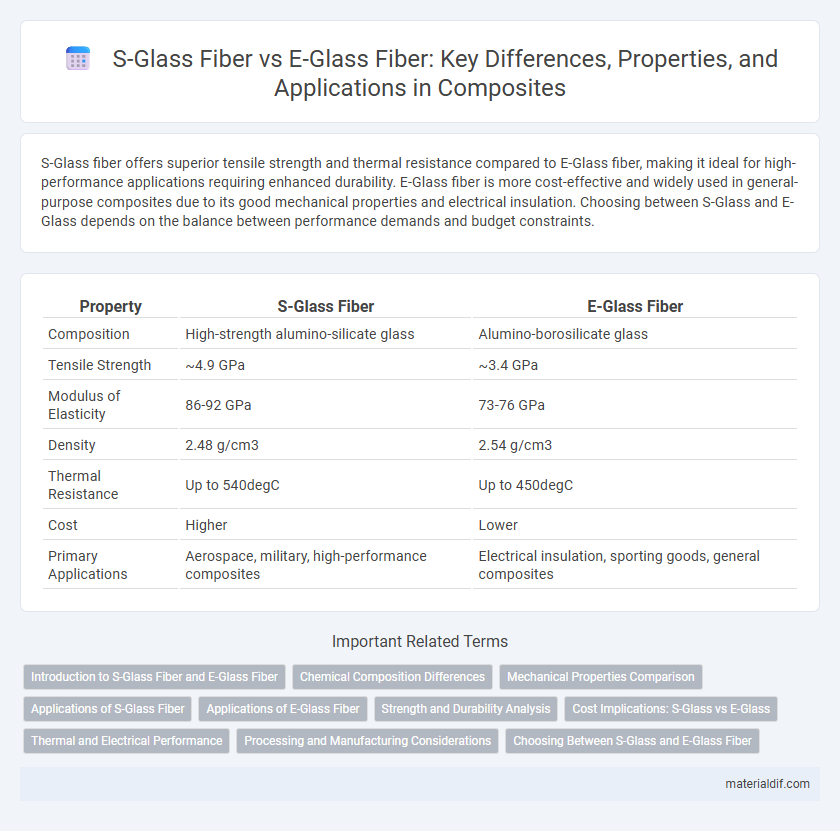

| Property | S-Glass Fiber | E-Glass Fiber |

|---|---|---|

| Composition | High-strength alumino-silicate glass | Alumino-borosilicate glass |

| Tensile Strength | ~4.9 GPa | ~3.4 GPa |

| Modulus of Elasticity | 86-92 GPa | 73-76 GPa |

| Density | 2.48 g/cm3 | 2.54 g/cm3 |

| Thermal Resistance | Up to 540degC | Up to 450degC |

| Cost | Higher | Lower |

| Primary Applications | Aerospace, military, high-performance composites | Electrical insulation, sporting goods, general composites |

Introduction to S-Glass Fiber and E-Glass Fiber

S-Glass fiber is a high-strength alumino-silicate glass fiber designed for advanced composite applications requiring superior tensile strength and enhanced thermal properties compared to conventional glass fibers. E-Glass fiber, commonly used in electronics and automotive industries, is an alumino-borosilicate glass fiber known for its excellent electrical insulation, corrosion resistance, and cost-effectiveness. Both fibers serve critical roles in composite manufacturing, with S-Glass favored for structural performance and E-Glass popular for versatility and affordability.

Chemical Composition Differences

S-Glass fiber primarily contains higher amounts of silica (SiO2) and alumina (Al2O3), which provide superior tensile strength and thermal resistance compared to E-Glass fiber. E-Glass fiber has a higher content of calcium oxide (CaO) and boron oxide (B2O3), enhancing its electrical insulating properties at a lower cost. The distinct chemical compositions result in S-Glass being favored for aerospace and military applications, while E-Glass is commonly used in general purpose composites and electrical insulation.

Mechanical Properties Comparison

S-Glass fiber exhibits higher tensile strength and modulus compared to E-Glass fiber, offering superior mechanical performance in high-stress applications. S-Glass fibers provide enhanced impact resistance and fatigue durability, making them ideal for aerospace and military composites requiring exceptional toughness. While E-Glass fibers deliver cost-effective corrosion resistance and good mechanical properties, S-Glass's advanced mechanical characteristics ensure better performance under dynamic loads and extreme conditions.

Applications of S-Glass Fiber

S-Glass fiber is widely used in aerospace, military, and high-performance sporting goods due to its superior tensile strength and impact resistance compared to E-Glass fiber. Its enhanced mechanical properties make it ideal for structural components requiring high fatigue resistance and lightweight characteristics. S-Glass fiber also finds applications in ballistic armor, pressure vessels, and automotive parts where elevated strength-to-weight ratios are critical.

Applications of E-Glass Fiber

E-Glass fiber is widely utilized in applications requiring high strength and electrical insulation, such as in printed circuit boards, automotive components, and wind turbine blades. Its excellent resistance to chemical attack and moisture makes it ideal for marine and construction industries, including reinforced plastics and composites. The cost-effectiveness and versatility of E-Glass fiber support its extensive use in aerospace and sporting goods manufacturing.

Strength and Durability Analysis

S-Glass fiber exhibits superior tensile strength and higher modulus compared to E-Glass fiber, making it ideal for applications requiring enhanced mechanical performance. Its improved durability against fatigue and environmental degradation ensures longer service life in demanding conditions. E-Glass fiber, while cost-effective, offers moderate strength and durability suitable for less critical structural uses.

Cost Implications: S-Glass vs E-Glass

S-Glass fiber generally incurs higher production costs compared to E-Glass fiber due to its superior tensile strength and enhanced thermal resistance properties, making it ideal for high-performance applications. E-Glass fiber offers a more cost-effective solution with satisfactory mechanical properties suitable for general industrial use, contributing to its widespread adoption. Choosing between S-Glass and E-Glass fibers involves balancing budget constraints with specific application requirements, where S-Glass justifies its premium price through improved durability and load-bearing capacity.

Thermal and Electrical Performance

S-Glass fiber exhibits superior thermal resistance with a higher decomposition temperature around 980degC compared to E-Glass fiber's limit near 840degC, making it more suitable for high-temperature applications. In terms of electrical performance, S-Glass offers enhanced dielectric strength and lower dielectric constant, resulting in better insulation properties under high-frequency conditions. These characteristics position S-Glass as the preferred choice over E-Glass fiber in environments requiring robust thermal stability and advanced electrical insulation.

Processing and Manufacturing Considerations

S-Glass fiber offers superior tensile strength and thermal resistance compared to E-Glass fiber, making its processing more demanding with higher temperature requirements during curing and handling. Manufacturing S-Glass fiber requires precise control over melting and drawing conditions to maintain fiber integrity, whereas E-Glass fiber benefits from more established, cost-effective production processes with greater tolerance for processing variations. The enhanced mechanical properties of S-Glass fiber often justify its complex manufacturing, particularly in high-performance applications like aerospace and defense composites.

Choosing Between S-Glass and E-Glass Fiber

S-Glass fiber offers superior tensile strength and higher modulus compared to E-Glass fiber, making it ideal for high-performance applications requiring enhanced mechanical properties. E-Glass fiber remains the most widely used due to its cost-effectiveness, excellent electrical insulation, and good chemical resistance. Selecting between S-Glass and E-Glass depends on balancing performance requirements with budget constraints and application-specific demands.

S-Glass Fiber vs E-Glass Fiber Infographic

materialdif.com

materialdif.com