Aramid fiber exhibits exceptional strength, heat resistance, and durability, making it ideal for protective gear and aerospace applications, while polyamide fiber, commonly known as nylon, offers flexibility, abrasion resistance, and ease of dyeing, benefiting apparel and industrial uses. Aramid fibers maintain structural integrity under high stress and temperature, whereas polyamide fibers excel in elasticity and moisture-wicking properties. Choosing between them depends on the specific performance requirements such as thermal stability versus stretch and comfort.

Table of Comparison

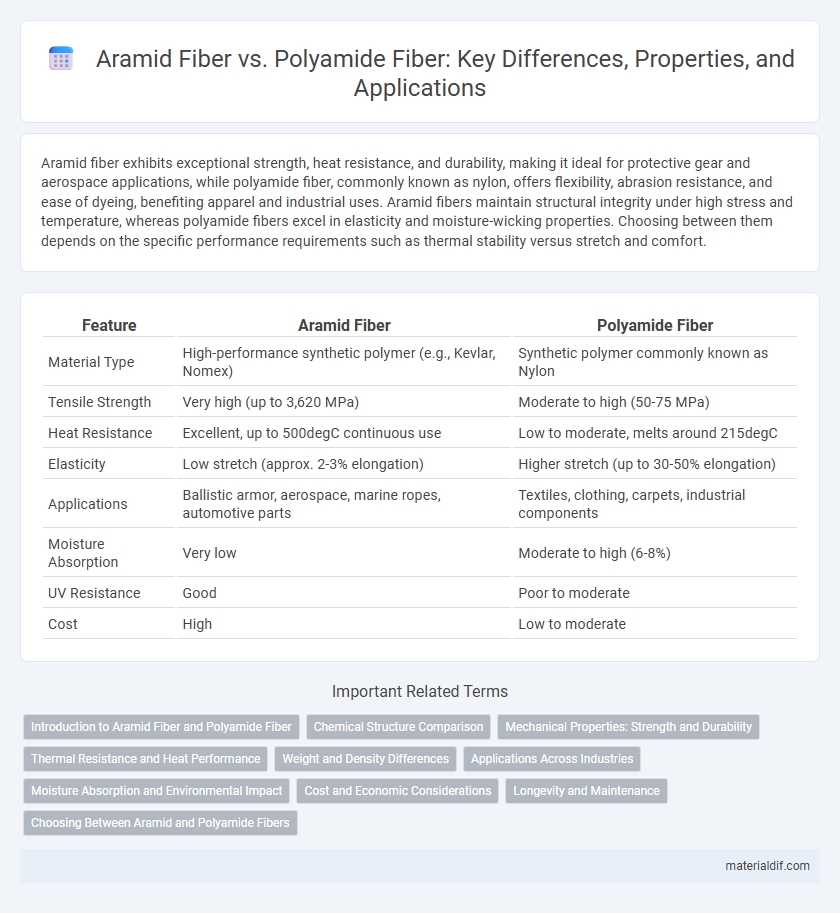

| Feature | Aramid Fiber | Polyamide Fiber |

|---|---|---|

| Material Type | High-performance synthetic polymer (e.g., Kevlar, Nomex) | Synthetic polymer commonly known as Nylon |

| Tensile Strength | Very high (up to 3,620 MPa) | Moderate to high (50-75 MPa) |

| Heat Resistance | Excellent, up to 500degC continuous use | Low to moderate, melts around 215degC |

| Elasticity | Low stretch (approx. 2-3% elongation) | Higher stretch (up to 30-50% elongation) |

| Applications | Ballistic armor, aerospace, marine ropes, automotive parts | Textiles, clothing, carpets, industrial components |

| Moisture Absorption | Very low | Moderate to high (6-8%) |

| UV Resistance | Good | Poor to moderate |

| Cost | High | Low to moderate |

Introduction to Aramid Fiber and Polyamide Fiber

Aramid fiber, a class of heat-resistant and strong synthetic fibers, is primarily used in aerospace, military applications, and protective gear due to its exceptional strength-to-weight ratio and thermal stability. Polyamide fiber, commonly known as nylon, is a versatile synthetic fiber valued for its elasticity, abrasion resistance, and wide use in apparel, industrial textiles, and consumer goods. Both fibers differ significantly in molecular structure, with aramid fibers featuring aromatic polyamides that provide superior durability and thermal resistance compared to the aliphatic polyamides found in nylon fibers.

Chemical Structure Comparison

Aramid fiber consists of aromatic polyamide chains with benzene rings linked by amide bonds, providing high tensile strength and thermal stability, while polyamide fiber features aliphatic chains without aromatic rings, offering more flexibility but lower heat resistance. The rigid molecular structure of aramid fibers results from the para-oriented benzene rings that enhance intermolecular hydrogen bonding, contrasting with the more amorphous and less ordered structure of polyamides like Nylon. These structural differences significantly influence their mechanical properties and applications, with aramid fibers favored in ballistic protection and polyamide fibers common in textiles and everyday apparel.

Mechanical Properties: Strength and Durability

Aramid fiber exhibits superior mechanical properties compared to polyamide fiber, with tensile strength reaching up to 3,000 MPa, making it ideal for high-performance applications requiring exceptional durability. Polyamide fiber, while offering good elasticity and abrasion resistance, typically demonstrates lower tensile strength around 900 MPa and reduced long-term durability under extreme conditions. The inherent molecular structure of aramid fibers provides enhanced resistance to heat and chemical degradation, ensuring prolonged mechanical integrity in demanding environments.

Thermal Resistance and Heat Performance

Aramid fiber exhibits superior thermal resistance withstanding continuous temperatures up to 370degC, making it ideal for high-heat applications like firefighting gear and aerospace components. Polyamide fiber, including nylon variants, generally has lower heat performance, typically degrading above 150degC, limiting its use in environments requiring sustained heat exposure. This significant difference highlights aramid fiber's advantage in thermal durability and safety-critical contexts.

Weight and Density Differences

Aramid fiber typically has a density of about 1.44 g/cm3, making it lighter than polyamide fiber, which ranges from 1.13 to 1.15 g/cm3. Despite polyamide's slightly lower density, aramid fibers offer superior strength-to-weight ratios, resulting in a lighter yet more durable material for high-performance applications. Weight considerations favor aramid fibers in aerospace and ballistic protection, where durability and minimal mass are critical.

Applications Across Industries

Aramid fiber excels in aerospace, military, and automotive industries due to its exceptional strength-to-weight ratio and high thermal resistance, making it ideal for bulletproof vests, aircraft components, and protective gear. Polyamide fiber, commonly known as nylon, is widely used in textiles, automotive parts, and consumer goods because of its durability, elasticity, and resistance to abrasion and chemicals. Both fibers serve critical roles across industries, with aramid favored for high-performance structural applications and polyamide preferred for versatile, everyday use.

Moisture Absorption and Environmental Impact

Aramid fibers exhibit extremely low moisture absorption, typically less than 0.5%, enhancing their dimensional stability and mechanical strength in humid conditions compared to polyamide fibers, which can absorb up to 8-10% moisture, leading to reduced performance. Environmentally, aramid fibers are more resistant to chemical degradation and have a longer service life, reducing waste, while polyamide fibers, being more biodegradable, pose lower long-term environmental persistence but generate microplastics during degradation. The choice between aramid and polyamide fibers depends on balancing moisture resistance requirements with environmental sustainability goals in applications ranging from aerospace to textiles.

Cost and Economic Considerations

Aramid fiber typically commands a higher price than polyamide fiber due to its superior strength and heat resistance, making it a preferred choice for high-performance applications despite greater upfront costs. Polyamide fiber remains more economically viable for general-use products where durability and flexibility are essential but extreme strength is not required. Cost-effectiveness depends largely on the specific application requirements, with aramid fibers justifying their expense in industries like aerospace and defense, while polyamide fibers dominate textiles and consumer goods for budget-conscious manufacturing.

Longevity and Maintenance

Aramid fiber offers exceptional longevity due to its high resistance to heat, abrasion, and chemical degradation, making it ideal for long-term, low-maintenance applications. Polyamide fiber, while durable and flexible, tends to absorb moisture, leading to faster wear and more frequent maintenance needs compared to aramid. Choosing aramid fiber can significantly reduce upkeep costs and extend product lifespan in demanding environments.

Choosing Between Aramid and Polyamide Fibers

Aramid fibers offer exceptional tensile strength, heat resistance, and durability, making them ideal for applications requiring high-performance materials such as body armor and aerospace components. Polyamide fibers, commonly known as nylon, provide superior elasticity, abrasion resistance, and chemical stability, which makes them suitable for everyday textile uses like clothing and industrial fabrics. Choosing between aramid and polyamide fibers depends on balancing the need for strength and thermal durability against flexibility and cost-effectiveness in the intended application.

Aramid Fiber vs Polyamide Fiber Infographic

materialdif.com

materialdif.com