Microfiber consists of extremely fine synthetic fibers that create a dense, soft texture ideal for cleaning and filtering applications, offering superior dirt and particle capture. Macro fiber, on the other hand, features thicker strands designed for structural reinforcement in concrete and composites, enhancing tensile strength and durability. Choosing between microfiber and macro fiber depends on whether the priority is fine filtration and softness or mechanical strength and reinforcement.

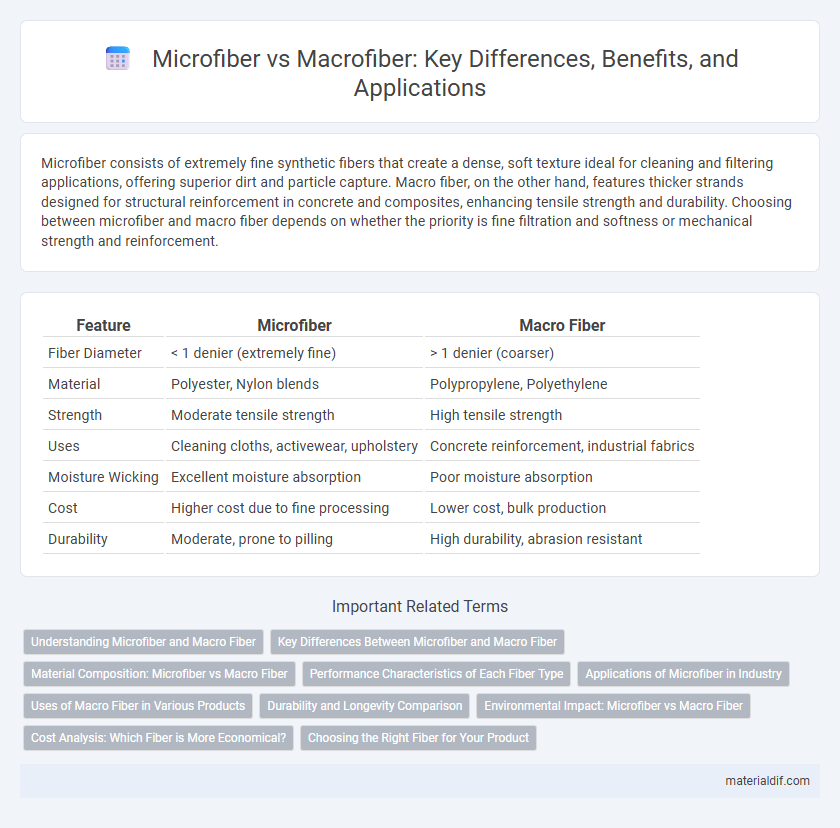

Table of Comparison

| Feature | Microfiber | Macro Fiber |

|---|---|---|

| Fiber Diameter | < 1 denier (extremely fine) | > 1 denier (coarser) |

| Material | Polyester, Nylon blends | Polypropylene, Polyethylene |

| Strength | Moderate tensile strength | High tensile strength |

| Uses | Cleaning cloths, activewear, upholstery | Concrete reinforcement, industrial fabrics |

| Moisture Wicking | Excellent moisture absorption | Poor moisture absorption |

| Cost | Higher cost due to fine processing | Lower cost, bulk production |

| Durability | Moderate, prone to pilling | High durability, abrasion resistant |

Understanding Microfiber and Macro Fiber

Microfiber consists of extremely fine synthetic fibers, typically less than 1 denier, which enables superior softness, breathability, and moisture-wicking properties in textiles. Macro fiber, with larger diameters usually above 1 denier, offers enhanced durability and structural strength, making it suitable for applications requiring robust performance. Understanding these differences helps in selecting the appropriate fiber type for specific uses in textile manufacturing, cleaning products, and composite materials.

Key Differences Between Microfiber and Macro Fiber

Microfiber consists of extremely fine synthetic fibers, typically less than one denier, providing superior softness, water absorption, and dirt trapping capability compared to macro fiber, which is thicker and often used for reinforcement in concrete and industrial applications. Microfiber excels in cleaning efficiency and moisture-wicking properties for textiles, while macro fiber contributes to structural strength and crack resistance in construction materials. The primary difference lies in their fiber thickness and purpose: microfibers prioritize tactile comfort and cleaning performance, whereas macro fibers focus on mechanical durability and reinforcement.

Material Composition: Microfiber vs Macro Fiber

Microfiber consists of extremely fine synthetic fibers, typically polyester or nylon, with diameters less than ten micrometers, allowing for enhanced softness and superior moisture-wicking properties. Macro fiber, made from thicker strands of materials such as polypropylene or natural fibers like cotton, offers greater durability and bulk but lacks the fine texture and high surface area of microfiber. The difference in material composition directly impacts performance characteristics, where microfiber excels in filtration and absorption while macro fiber is preferred for structural strength and resilience.

Performance Characteristics of Each Fiber Type

Microfiber offers superior moisture-wicking and breathability due to its ultra-fine strands, enhancing comfort and quick drying in activewear and cleaning applications. Macro fiber provides greater durability and tensile strength, making it ideal for heavy-duty reinforcement in concrete and industrial textiles. The choice between microfiber and macro fiber depends on specific performance needs, balancing flexibility and lightweight properties against robustness and structural support.

Applications of Microfiber in Industry

Microfiber, characterized by fibers finer than one denier, offers superior surface area and flexibility compared to macro fiber, making it ideal for diverse industrial applications such as filtration, composite reinforcements, and high-performance textiles. Its enhanced mechanical properties and ability to improve durability and strength in products drive its usage in automotive, aerospace, and protective gear manufacturing. Industries benefit from microfiber's capacity to increase material efficiency while reducing weight and improving performance.

Uses of Macro Fiber in Various Products

Macro fibers are widely used in construction materials to enhance structural integrity, particularly in concrete reinforcement for slabs, walls, and shotcrete. These fibers improve durability, impact resistance, and crack control in industrial floors, tunnels, and precast concrete products. Their application also extends to composite materials in automotive and aerospace industries, where increased tensile strength and fatigue resistance are critical.

Durability and Longevity Comparison

Microfiber offers superior durability due to its fine synthetic strands that resist wear, fading, and pilling better than macro fiber. Macro fibers, being thicker, provide robust physical strength but are more prone to wear and tear over time, reducing their longevity under heavy use. Microfiber's enhanced resistance to abrasion and staining ensures extended lifespan, making it ideal for high-traffic applications requiring sustained durability.

Environmental Impact: Microfiber vs Macro Fiber

Microfiber contributes to significant environmental pollution due to its minute size, which easily bypasses filtration systems and accumulates in aquatic ecosystems, harming marine life and entering food chains. Macro fiber, being larger, is less likely to disperse into water bodies but can still cause environmental damage through physical entanglement and slower biodegradation rates. Choosing sustainable fibers and improving filtration technologies are critical to mitigating the ecological footprint of both micro and macro fibers.

Cost Analysis: Which Fiber is More Economical?

Microfiber typically offers a lower initial cost per yard compared to macro fiber, making it more economical for projects requiring extensive coverage. However, macro fiber's superior durability and reduced maintenance expenses can lead to lower long-term costs in applications like concrete reinforcement. Cost analysis must balance upfront material price against lifespan and performance metrics to determine overall economic value.

Choosing the Right Fiber for Your Product

Microfiber offers superior softness, enhanced moisture-wicking properties, and finer filtration capabilities, making it ideal for high-performance textiles and sensitive cleaning applications. Macro fiber provides greater durability, structural support, and cost-effectiveness, suitable for rugged products like upholstery and industrial fabrics. Selecting the right fiber depends on your product's functional requirements, balancing texture, strength, and budget considerations.

Microfiber vs Macro Fiber Infographic

materialdif.com

materialdif.com