Unidirectional fiber offers superior strength and stiffness along a single axis, making it ideal for applications requiring high tensile strength in one direction. Multidirectional fiber, composed of layers oriented in various directions, provides enhanced overall durability and resistance to impact by distributing loads more evenly. Choosing between unidirectional and multidirectional fiber depends on the specific mechanical demands and load conditions of the project.

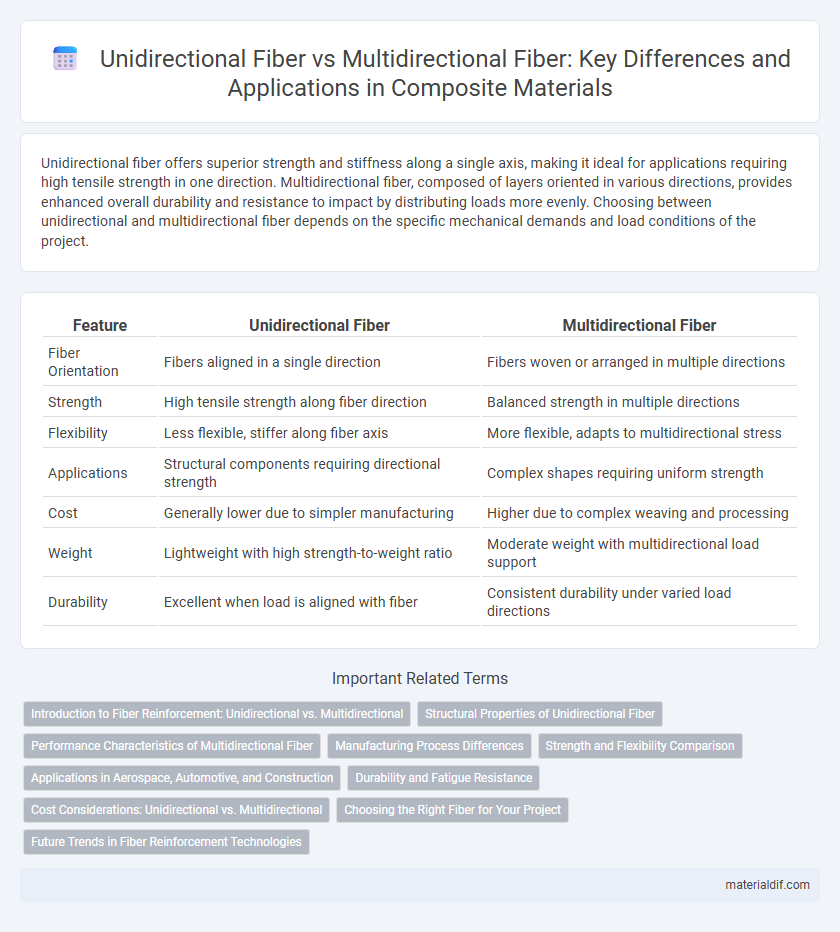

Table of Comparison

| Feature | Unidirectional Fiber | Multidirectional Fiber |

|---|---|---|

| Fiber Orientation | Fibers aligned in a single direction | Fibers woven or arranged in multiple directions |

| Strength | High tensile strength along fiber direction | Balanced strength in multiple directions |

| Flexibility | Less flexible, stiffer along fiber axis | More flexible, adapts to multidirectional stress |

| Applications | Structural components requiring directional strength | Complex shapes requiring uniform strength |

| Cost | Generally lower due to simpler manufacturing | Higher due to complex weaving and processing |

| Weight | Lightweight with high strength-to-weight ratio | Moderate weight with multidirectional load support |

| Durability | Excellent when load is aligned with fiber | Consistent durability under varied load directions |

Introduction to Fiber Reinforcement: Unidirectional vs. Multidirectional

Unidirectional fiber reinforcement consists of fibers aligned in a single direction, providing maximum strength and stiffness along the fiber axis, ideal for applications requiring high tensile properties. Multidirectional fiber reinforcement involves fibers oriented in multiple directions, enhancing isotropic strength and durability by distributing loads across various axes. The choice between unidirectional and multidirectional fiber composites depends on structural requirements and load-bearing complexity in engineering and manufacturing.

Structural Properties of Unidirectional Fiber

Unidirectional fibers exhibit high tensile strength and stiffness along the fiber axis due to their parallel alignment, which enhances load-bearing capacity in a single direction. Their anisotropic structural properties result in superior performance for applications requiring targeted reinforcement, such as aerospace and automotive components. This alignment also improves resistance to fatigue and impact in the specific direction of the fibers, making unidirectional composites ideal for optimized strength-to-weight ratios.

Performance Characteristics of Multidirectional Fiber

Multidirectional fiber offers superior spatial coverage by capturing light signals from multiple directions, enhancing signal reliability and reducing sensitivity to misalignment or bending losses. Its design supports higher data transmission rates with improved resilience in dynamic environments, making it ideal for applications requiring robust connectivity. The fiber's ability to maintain consistent performance under varied conditions results in lower attenuation and minimized signal degradation compared to unidirectional fibers.

Manufacturing Process Differences

Unidirectional fiber manufacturing involves aligning fibers uniformly in a single direction, enhancing tensile strength and stiffness along that axis. Multidirectional fiber production integrates fibers oriented at varying angles, typically through layering or weaving methods, to improve strength and durability across multiple planes. These distinct manufacturing processes dictate the mechanical properties and application suitability of composite materials in industries such as aerospace and automotive engineering.

Strength and Flexibility Comparison

Unidirectional fiber offers superior tensile strength along the fiber axis, making it ideal for applications requiring maximum load-bearing capacity in one direction. Multidirectional fiber provides enhanced flexibility and impact resistance by distributing strength across multiple orientations, allowing better performance under complex stress conditions. The choice between unidirectional and multidirectional fiber depends on whether priority is given to directional strength or overall structural flexibility.

Applications in Aerospace, Automotive, and Construction

Unidirectional fiber offers superior tensile strength and stiffness, making it ideal for aerospace components that require high load-bearing capacity and weight reduction, such as aircraft wings and fuselage structures. Multidirectional fiber provides enhanced impact resistance and flexibility, suitable for automotive parts like chassis reinforcements and crash-resistant panels, as well as complex architectural elements in construction that demand multidirectional stress distribution. Both fiber types optimize performance and durability in their respective applications by aligning fiber orientation with specific mechanical requirements and environmental conditions.

Durability and Fatigue Resistance

Unidirectional fiber composites exhibit superior fatigue resistance and durability due to fiber alignment that effectively carries loads along a single axis, minimizing stress concentrations and crack initiation. In contrast, multidirectional fibers enhance impact resistance and distribute loads across multiple directions but may experience reduced fatigue life under cyclic stresses. Selecting between unidirectional and multidirectional fibers depends on the specific structural demands, with unidirectional fibers favored for high-cycle fatigue applications requiring long-term durability.

Cost Considerations: Unidirectional vs. Multidirectional

Unidirectional fiber typically incurs lower material and installation costs due to its straightforward alignment and reduced complexity in deployment. Multidirectional fiber demands higher investment driven by intricate network design, increased connector and splice count, and advanced routing requirements. Cost efficiency in fiber optic projects depends significantly on selecting the appropriate fiber type aligned with specific network topology and scalability needs.

Choosing the Right Fiber for Your Project

Unidirectional fiber offers superior tensile strength and stiffness along a single axis, making it ideal for applications requiring high load-bearing capacity in one direction, such as aerospace or sporting goods. Multidirectional fiber provides balanced strength and flexibility by combining fibers oriented in multiple directions, suitable for complex geometries and components subjected to multidirectional stresses, like automotive parts or wind turbine blades. Selecting the right fiber depends on the structural demands, load patterns, and manufacturing processes specific to your project requirements.

Future Trends in Fiber Reinforcement Technologies

Unidirectional fiber offers superior tensile strength and stiffness along a single axis, making it ideal for high-performance applications in aerospace and automotive industries. Multidirectional fiber enhances isotropic properties by weaving fibers in multiple orientations, improving impact resistance and durability in composite materials. Future trends in fiber reinforcement technologies emphasize hybrid fiber systems and nanofiber integration to optimize mechanical performance and weight reduction across advanced structural components.

Unidirectional Fiber vs Multidirectional Fiber Infographic

materialdif.com

materialdif.com