High-tenacity fiber offers superior strength and durability, making it ideal for applications requiring enhanced resistance to wear and tear. Low-tenacity fiber, while less robust, provides greater flexibility and is often used in products where softness and lightness are prioritized. Choosing between the two depends on the specific performance requirements of the end-use product.

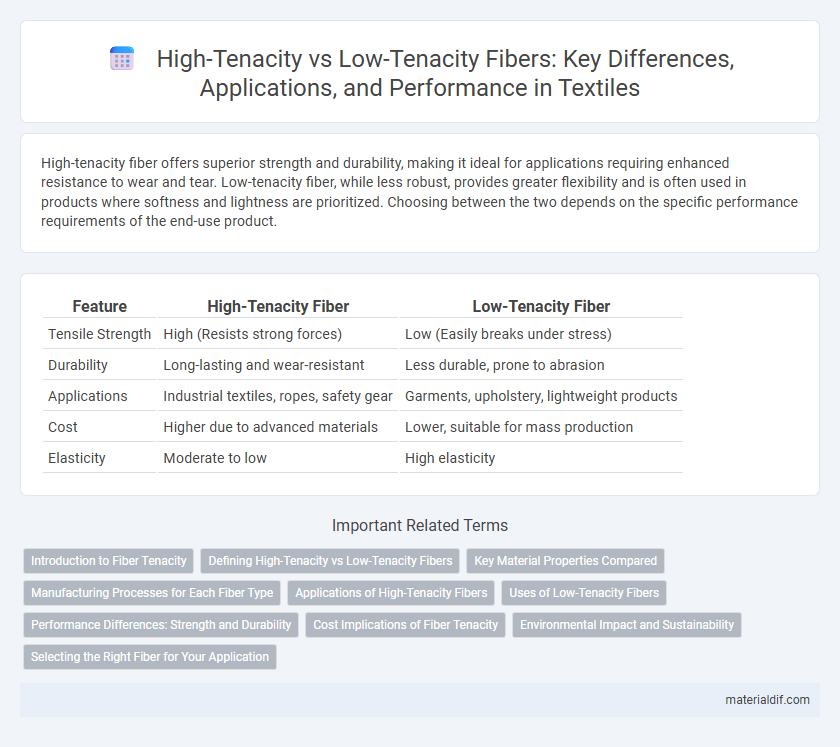

Table of Comparison

| Feature | High-Tenacity Fiber | Low-Tenacity Fiber |

|---|---|---|

| Tensile Strength | High (Resists strong forces) | Low (Easily breaks under stress) |

| Durability | Long-lasting and wear-resistant | Less durable, prone to abrasion |

| Applications | Industrial textiles, ropes, safety gear | Garments, upholstery, lightweight products |

| Cost | Higher due to advanced materials | Lower, suitable for mass production |

| Elasticity | Moderate to low | High elasticity |

Introduction to Fiber Tenacity

High-tenacity fiber exhibits superior tensile strength, enabling it to withstand greater stress and strain before breaking, making it essential for demanding applications like industrial ropes and high-performance textiles. Low-tenacity fiber, conversely, offers less resistance to tension but provides flexibility and softness, suitable for comfort-oriented fabrics and lightweight materials. Understanding fiber tenacity is crucial for selecting the appropriate fiber type based on mechanical durability and end-use requirements.

Defining High-Tenacity vs Low-Tenacity Fibers

High-tenacity fibers are engineered to exhibit exceptional strength and durability, often measured by their high tensile strength values typically exceeding 5 grams per denier (g/d). In contrast, low-tenacity fibers possess lower tensile strength, generally below 3 g/d, making them more prone to breakage under stress but often more flexible and cost-effective. The distinction between high-tenacity and low-tenacity fibers is crucial in applications demanding either robust performance or economic efficiency.

Key Material Properties Compared

High-tenacity fiber exhibits superior tensile strength, high modulus, and excellent durability, making it ideal for demanding applications like industrial textiles and composites. Low-tenacity fiber typically offers greater flexibility and elongation but lower strength and abrasion resistance, suited for comfort-oriented uses such as apparel and upholstery. The choice between high-tenacity and low-tenacity fibers depends on balancing mechanical performance requirements with fabric hand and end-use functionality.

Manufacturing Processes for Each Fiber Type

High-tenacity fibers are manufactured through specialized processes such as high-draw ratio spinning and orienting techniques that enhance molecular alignment and crystallinity, resulting in superior tensile strength. Low-tenacity fibers typically undergo standard melt spinning or solution spinning processes without extensive molecular orientation, yielding fibers with moderate strength and greater flexibility. Advanced stretching and heat-setting methods differentiate high-tenacity fiber production by improving structural integrity essential for demanding industrial applications.

Applications of High-Tenacity Fibers

High-tenacity fibers, known for their exceptional strength and durability, are widely used in demanding applications such as industrial rope manufacturing, ballistic protection, and high-performance composites. These fibers enhance the mechanical properties of materials in aerospace, automotive, and military sectors, ensuring safety and longevity under extreme conditions. Their superior tensile strength compared to low-tenacity fibers makes them ideal for environments requiring enhanced resistance to abrasion, impact, and environmental stress.

Uses of Low-Tenacity Fibers

Low-tenacity fibers are primarily used in applications where flexibility and softness are more critical than strength, such as in textiles for clothing, upholstery, and household fabrics. These fibers offer excellent comfort and breathability, making them ideal for apparel and decorative purposes. Their lower strength compared to high-tenacity fibers limits their use in industrial or heavy-duty contexts but provides advantages in everyday fabric applications.

Performance Differences: Strength and Durability

High-tenacity fibers exhibit superior tensile strength and durability, making them ideal for applications requiring resistance to mechanical stress and long-term wear. Low-tenacity fibers, by contrast, have reduced strength and are more susceptible to abrasion and fatigue, limiting their use in high-performance environments. The enhanced molecular alignment and higher crystallinity in high-tenacity fibers contribute to their improved load-bearing capacity and extended lifespan.

Cost Implications of Fiber Tenacity

High-tenacity fibers offer superior strength and durability, leading to longer-lasting products that reduce replacement frequency and maintenance costs. Low-tenacity fibers are generally less expensive upfront but may incur higher lifecycle costs due to increased wear and tear. Selecting fiber tenacity directly impacts overall project budgets through trade-offs between initial investment and long-term performance expenses.

Environmental Impact and Sustainability

High-tenacity fiber offers greater durability and a longer lifecycle, significantly reducing waste and resource consumption compared to low-tenacity fiber. Production of high-tenacity fibers often requires fewer raw materials for the same performance level, lowering the overall environmental footprint. Low-tenacity fibers typically degrade faster, leading to more frequent replacement and increased environmental burden through higher energy use and landfill contribution.

Selecting the Right Fiber for Your Application

High-tenacity fiber offers superior strength and durability, making it ideal for applications requiring resistance to abrasion, heavy loads, and long-term performance, such as industrial ropes, safety harnesses, and reinforcement materials. Low-tenacity fiber provides flexibility and cost-effectiveness, suitable for lighter-duty applications like apparel, upholstery, and decorative textiles where softness and comfort are prioritized. Selecting the right fiber depends on balancing tensile strength, elasticity, weight, and environmental exposure specific to your project's requirements.

High-tenacity Fiber vs Low-tenacity Fiber Infographic

materialdif.com

materialdif.com