Wet-spun fibers are produced by extruding polymer solutions into a coagulation bath, resulting in fibers with high tensile strength and uniformity ideal for delicate and high-performance textiles. Dry-spun fibers involve evaporating solvent from the polymer solution as it exits the spinneret, producing fibers with a porous structure suitable for applications requiring lightweight and breathable materials. Choosing between wet-spun and dry-spun fibers depends on the desired fiber properties and the specific end-use in textiles or composites.

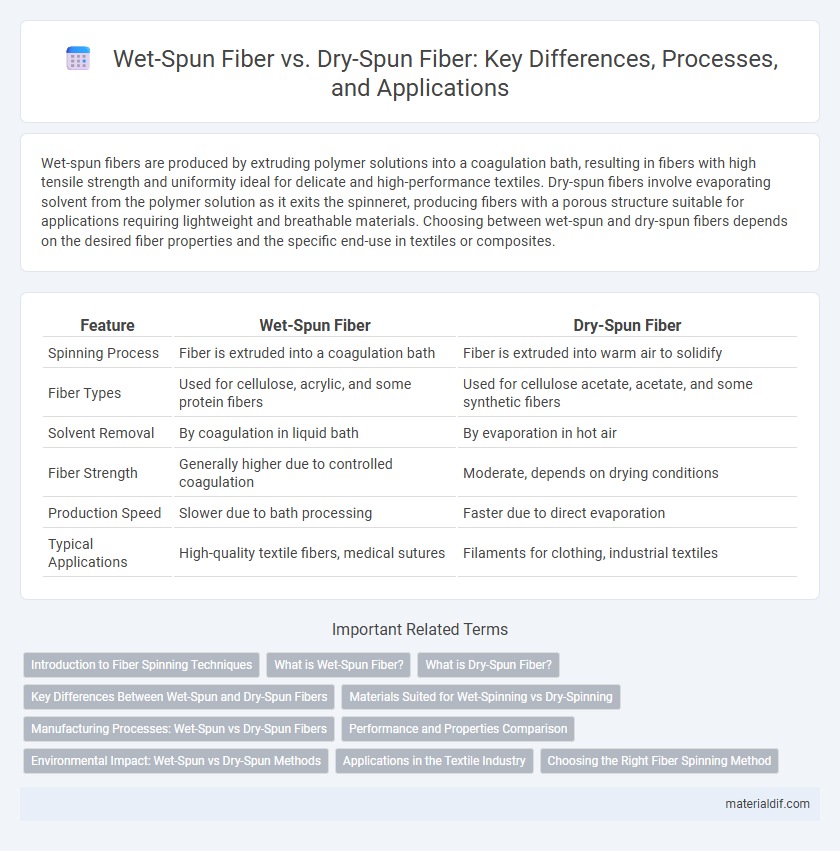

Table of Comparison

| Feature | Wet-Spun Fiber | Dry-Spun Fiber |

|---|---|---|

| Spinning Process | Fiber is extruded into a coagulation bath | Fiber is extruded into warm air to solidify |

| Fiber Types | Used for cellulose, acrylic, and some protein fibers | Used for cellulose acetate, acetate, and some synthetic fibers |

| Solvent Removal | By coagulation in liquid bath | By evaporation in hot air |

| Fiber Strength | Generally higher due to controlled coagulation | Moderate, depends on drying conditions |

| Production Speed | Slower due to bath processing | Faster due to direct evaporation |

| Typical Applications | High-quality textile fibers, medical sutures | Filaments for clothing, industrial textiles |

Introduction to Fiber Spinning Techniques

Wet-spun fiber involves extruding a polymer solution into a coagulation bath, allowing fibers to form through solvent exchange, which is ideal for materials sensitive to heat. Dry-spun fiber is produced by extruding a polymer solution into warm air, causing solvent evaporation to solidify the fibers, suitable for thermally stable polymers. Both techniques influence fiber properties such as tensile strength, porosity, and morphology, impacting their application in textiles, medical devices, and composites.

What is Wet-Spun Fiber?

Wet-spun fiber is produced by extruding a polymer solution into a coagulation bath, where the liquid polymer solidifies into continuous filaments. This technique is commonly used for fibers that are sensitive to heat or require precise control of fiber morphology, such as rayon, acrylic, and spandex. Wet-spinning enables the creation of fibers with high tensile strength, uniformity, and fine denier, essential for advanced textile applications.

What is Dry-Spun Fiber?

Dry-spun fiber is produced by extruding a polymer solution into a warm gas environment, causing the solvent to evaporate and solidify the fiber. This method is ideal for polymers that dissolve in volatile solvents and enables precise control over fiber morphology and mechanical properties. Dry spinning is commonly used for fibers like acetate, spandex, and modacrylic, offering versatility in textile and industrial applications.

Key Differences Between Wet-Spun and Dry-Spun Fibers

Wet-spun fibers are produced by extruding a polymer solution into a coagulation bath, causing the fiber to solidify through chemical precipitation, resulting in high strength and fine filament structures ideal for delicate textiles. Dry-spun fibers, on the other hand, are formed by evaporating a solvent from the polymer solution in warm air, producing fibers with a more porous structure suitable for breathable and moisture-wicking applications. The key differences lie in the spinning environment, fiber morphology, and resulting mechanical properties which determine their use in various textile and industrial applications.

Materials Suited for Wet-Spinning vs Dry-Spinning

Wet-spun fibers are ideally suited for materials like cellulose, acrylics, and some synthetic polymers that require dissolution in a solvent and coagulation in a liquid bath for fiber formation. Dry-spun fibers, on the other hand, are compatible with thermoplastic polymers such as acetate, spandex, and some polyamides, where the polymer solution is evaporated to solidify the fiber. Selection depends on polymer solubility, desired fiber properties, and production efficiency.

Manufacturing Processes: Wet-Spun vs Dry-Spun Fibers

Wet-spun fibers are manufactured by extruding a polymer solution into a coagulation bath, which solidifies the fiber through solvent exchange or chemical reaction, suitable for cellulose and certain synthetic polymers. Dry-spinning involves evaporating the solvent by passing the polymer solution through a heated chamber, enabling rapid fiber formation for polymers like cellulose acetate and spandex. The choice between wet-spinning and dry-spinning depends on polymer solubility, desired fiber properties, and processing conditions.

Performance and Properties Comparison

Wet-spun fibers exhibit higher tensile strength and improved uniformity due to their controlled coagulation process, resulting in enhanced mechanical properties suitable for high-performance textiles. Dry-spun fibers generally offer greater porosity and flexibility, making them ideal for applications requiring breathability and softer textures. The choice between wet-spun and dry-spun fibers depends on specific performance needs such as durability, elasticity, and moisture management in end-use products.

Environmental Impact: Wet-Spun vs Dry-Spun Methods

Wet-spun fibers generate higher water waste and energy consumption due to solvent-intensive coagulation baths, significantly increasing environmental pollution and resource use. Dry-spun fibers use volatile organic solvents that require recovery systems, yet generally consume less water and have lower overall wastewater discharge. Advances in solvent recycling technologies and greener solvents are crucial for reducing the ecological footprint in both wet-spinning and dry-spinning fiber production methods.

Applications in the Textile Industry

Wet-spun fiber offers superior strength and uniformity, making it ideal for high-performance textiles such as surgical sutures, tire cords, and bulletproof vests where durability is critical. Dry-spun fiber, characterized by its lightweight and elasticity, is widely used in applications like sportswear, lingerie, and seamless garments where comfort and stretchability are prioritized. Both spinning methods enable the production of specialized fibers tailored to meet specific functional requirements in the textile industry.

Choosing the Right Fiber Spinning Method

Selecting the appropriate fiber spinning method depends on the polymer's solubility and desired fiber properties. Wet-spun fibers involve extruding a polymer solution into a coagulation bath, creating fibers with higher uniformity and strength, ideal for materials like rayon and acrylics. Dry-spun fibers are produced by evaporating solvents from the polymer solution in warm air, offering faster production rates suited for cellulose acetate and spandex fibers.

Wet-Spun Fiber vs Dry-Spun Fiber Infographic

materialdif.com

materialdif.com