Monofilament fiber consists of a single, continuous strand, offering high tensile strength and superior resistance to abrasion, making it ideal for applications requiring durability and longevity. Multifilament fiber is composed of multiple smaller filaments twisted or braided together, providing enhanced flexibility, softness, and better moisture-wicking properties for comfort and breathability. Choosing between monofilament and multifilament fiber depends on the specific needs for strength versus flexibility in pet products.

Table of Comparison

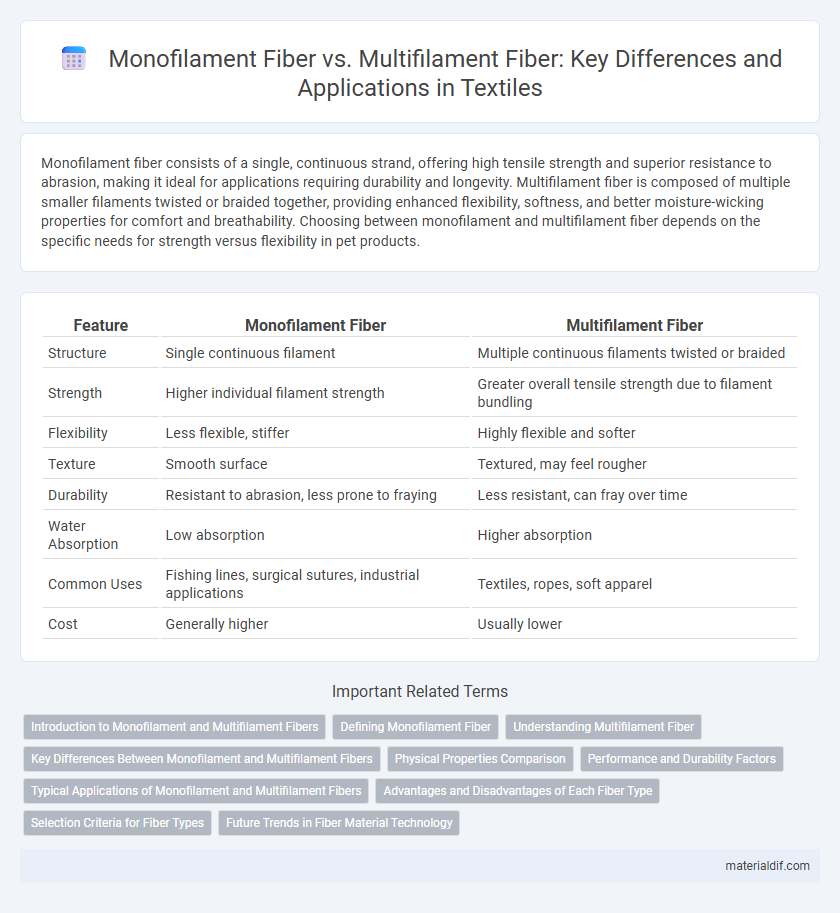

| Feature | Monofilament Fiber | Multifilament Fiber |

|---|---|---|

| Structure | Single continuous filament | Multiple continuous filaments twisted or braided |

| Strength | Higher individual filament strength | Greater overall tensile strength due to filament bundling |

| Flexibility | Less flexible, stiffer | Highly flexible and softer |

| Texture | Smooth surface | Textured, may feel rougher |

| Durability | Resistant to abrasion, less prone to fraying | Less resistant, can fray over time |

| Water Absorption | Low absorption | Higher absorption |

| Common Uses | Fishing lines, surgical sutures, industrial applications | Textiles, ropes, soft apparel |

| Cost | Generally higher | Usually lower |

Introduction to Monofilament and Multifilament Fibers

Monofilament fibers consist of a single continuous filament, offering high strength and smooth texture, commonly used in applications requiring durability and minimal friction. Multifilament fibers are composed of multiple fine filaments twisted or spun together, providing enhanced flexibility, softness, and improved moisture wicking, ideal for textiles and industrial uses. Understanding the structural differences between monofilament and multifilament fibers is crucial for selecting the appropriate fiber type based on performance requirements in sectors like fishing, medical sutures, and apparel.

Defining Monofilament Fiber

Monofilament fiber consists of a single continuous filament, offering high tensile strength and smooth surface texture ideal for precise industrial applications. This type of fiber is commonly used in fishing lines, surgical sutures, and filtration because of its durability and resistance to abrasion. Its uniform structure enables consistent performance in products requiring minimal friction and maximum strength.

Understanding Multifilament Fiber

Multifilament fiber consists of multiple continuous filaments twisted or spun together, offering enhanced strength, flexibility, and durability compared to monofilament fibers. This fiber type is widely used in textiles, fishing lines, and medical sutures due to its superior tensile strength and resistance to abrasion. Understanding multifilament fiber's structure helps optimize applications requiring high performance and resilience under stress.

Key Differences Between Monofilament and Multifilament Fibers

Monofilament fibers consist of a single, continuous filament providing high tensile strength and smooth texture, making them ideal for applications requiring durability and minimal friction. Multifilament fibers are composed of multiple fine filaments twisted or braided together, offering greater flexibility, softness, and enhanced moisture-wicking properties. Key differences include monofilament's superior abrasion resistance and stiffness versus multifilament's improved elasticity, breathability, and comfort in textile and industrial uses.

Physical Properties Comparison

Monofilament fiber consists of a single, continuous filament, offering high tensile strength, low elongation, and smooth surface texture, ideal for precise applications requiring durability and minimal friction. Multifilament fiber comprises multiple fine filaments twisted together, providing greater flexibility, higher elongation, and enhanced softness, which improves comfort and abrasion resistance. The choice between monofilament and multifilament fibers depends on the balance needed between strength, flexibility, and tactile properties for specific industrial or textile uses.

Performance and Durability Factors

Monofilament fiber offers high tensile strength and excellent abrasion resistance, making it ideal for applications requiring durability and minimal stretch. Multifilament fiber provides superior flexibility and softness, enhancing comfort but may be more prone to fraying under heavy wear. Performance in harsh environments typically favors monofilament for long-term resilience, while multifilament excels in dynamic uses needing elasticity and smooth texture.

Typical Applications of Monofilament and Multifilament Fibers

Monofilament fibers are commonly used in applications requiring high durability and stiffness, such as fishing lines, surgical sutures, and industrial filtration systems. Multifilament fibers find typical applications in textiles, ropes, and medical textiles due to their flexibility, softness, and enhanced strength through multiple strands. Both fiber types serve crucial roles in different industries, optimized for performance characteristics aligned with end-use requirements.

Advantages and Disadvantages of Each Fiber Type

Monofilament fiber offers high strength, durability, and resistance to abrasion, making it ideal for applications requiring minimal fiber movement and low water absorption, but it tends to be less flexible and can be more prone to breakage under repetitive stress. Multifilament fiber provides superior flexibility, softness, and better drape due to its multiple fine filaments, enhancing comfort and reducing pilling; however, it can absorb more moisture, has lower tensile strength per filament, and may experience wear more quickly in abrasive environments. Choosing between monofilament and multifilament fibers depends on balancing the need for strength and rigidity against flexibility and comfort in specific textile or industrial uses.

Selection Criteria for Fiber Types

Selection criteria for monofilament and multifilament fibers hinge on application-specific requirements such as strength, flexibility, and durability. Monofilament fibers offer higher tensile strength and low moisture absorption, making them ideal for high-stress environments and precise textile applications. Multifilament fibers provide enhanced softness, flexibility, and better resistance to abrasion, preferred in uses demanding comfort and resilience like sportswear and upholstery.

Future Trends in Fiber Material Technology

Monofilament fibers, characterized by their single continuous filament structure, offer superior strength and precision, while multifilament fibers, composed of multiple fine filaments, provide enhanced flexibility and softness. Future trends in fiber material technology emphasize the development of hybrid fibers combining monofilament's durability with multifilament's comfort, driven by advancements in nanotechnology and bio-based polymers. Innovations focus on sustainable production methods and smart fiber functionalities, such as self-healing and adaptive properties, revolutionizing applications in textiles, medical devices, and industrial uses.

Monofilament Fiber vs Multifilament Fiber Infographic

materialdif.com

materialdif.com