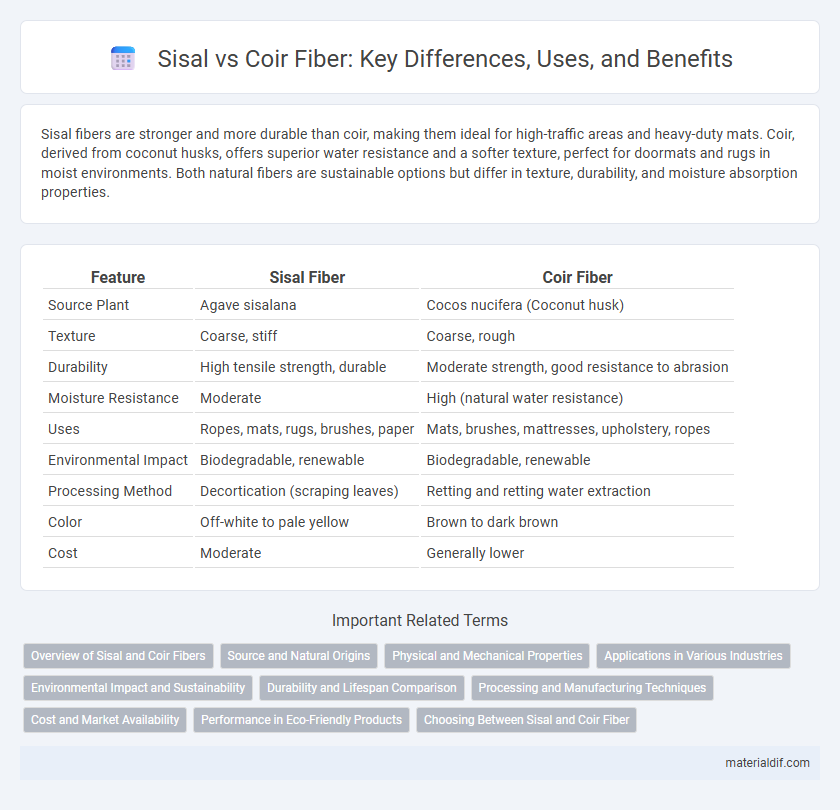

Sisal fibers are stronger and more durable than coir, making them ideal for high-traffic areas and heavy-duty mats. Coir, derived from coconut husks, offers superior water resistance and a softer texture, perfect for doormats and rugs in moist environments. Both natural fibers are sustainable options but differ in texture, durability, and moisture absorption properties.

Table of Comparison

| Feature | Sisal Fiber | Coir Fiber |

|---|---|---|

| Source Plant | Agave sisalana | Cocos nucifera (Coconut husk) |

| Texture | Coarse, stiff | Coarse, rough |

| Durability | High tensile strength, durable | Moderate strength, good resistance to abrasion |

| Moisture Resistance | Moderate | High (natural water resistance) |

| Uses | Ropes, mats, rugs, brushes, paper | Mats, brushes, mattresses, upholstery, ropes |

| Environmental Impact | Biodegradable, renewable | Biodegradable, renewable |

| Processing Method | Decortication (scraping leaves) | Retting and retting water extraction |

| Color | Off-white to pale yellow | Brown to dark brown |

| Cost | Moderate | Generally lower |

Overview of Sisal and Coir Fibers

Sisal fibers, derived from the Agave sisalana plant, are known for their strength, durability, and natural resistance to moisture and wear, making them ideal for ropes, mats, and rugs. Coir fibers come from the outer husk of coconuts and are recognized for their coarse texture, excellent water resistance, and cushioning properties, often used in doormats, brushes, and upholstery padding. Both fibers are sustainable, biodegradable, and widely utilized in eco-friendly products across various industries.

Source and Natural Origins

Sisal fiber is derived from the Agave sisalana plant native to Mexico and parts of Central America, known for its long, stiff fibers ideal for ropes and mats. Coir fiber, extracted from the outer husk of coconut shells, primarily comes from coastal regions in India, Sri Lanka, and the Philippines, valued for its coarse texture and water-resistant properties. Both fibers are renewable natural materials, with sisal sourced from succulent leaves and coir from fibrous fruit husks, reflecting distinct botanical origins and physical characteristics.

Physical and Mechanical Properties

Sisal fibers exhibit higher tensile strength, averaging around 400 MPa, compared to coir fibers which typically range between 150-250 MPa, making sisal more suitable for load-bearing applications. Coir fibers have greater elongation at break, often exceeding 40%, providing superior flexibility but lower stiffness relative to the more rigid sisal fibers. The density of sisal averages 1.45 g/cm3, which is lower than coir's approximately 1.2 g/cm3, influencing their respective uses where lightweight materials are preferred.

Applications in Various Industries

Sisal fiber, derived from the Agave plant, is extensively used in automotive upholstery, geotextiles, and home furnishings due to its durability and strength. Coir fiber, sourced from coconut husks, excels in mattress manufacturing, erosion control mats, and horticultural products because of its resilience and water retention properties. Both fibers play crucial roles in sustainable packaging and eco-friendly biodegradable composite materials across multiple industries.

Environmental Impact and Sustainability

Sisal fiber, derived from the Agave sisalana plant, offers biodegradable and renewable properties with a lower water footprint compared to coir, which is extracted from coconut husks and often involves more extensive processing that can lead to higher energy consumption. Coir production benefits from utilizing coconut waste, supporting waste valorization and reducing landfill use, but it may contribute to deforestation if not sourced sustainably. Both fibers contribute to soil erosion control and carbon sequestration, yet sisal's faster growth rate and greater yield enhance its environmental sustainability profile over coir in large-scale applications.

Durability and Lifespan Comparison

Sisal fibers exhibit higher durability and a longer lifespan compared to coir due to their stronger tensile strength and resistance to wear and tear, making them suitable for high-traffic areas. Coir, derived from coconut husks, offers excellent water resistance but tends to degrade faster under consistent friction and exposure to sunlight. Sisal's robust natural properties enable it to maintain structural integrity for several years, whereas coir typically lasts around 2-3 years under similar conditions.

Processing and Manufacturing Techniques

Sisal fiber processing involves decorticating the leaves to separate fibers, followed by drying and brushing to achieve a smooth texture, commonly used in making ropes and mats. Coir processing requires retting of coconut husks in water to soften fibers, then defibering using mechanical beaters before drying, which results in coarser, more durable strands ideal for doormats and upholstery. Manufacturing techniques for sisal prioritize fiber alignment and tensile strength, while coir production emphasizes durability and water resistance through the retting and extraction methods.

Cost and Market Availability

Sisal fiber generally costs more than coir due to its higher tensile strength and processing requirements, while coir remains more affordable and widely used in budget-friendly products. Market availability of coir is broader, especially in tropical regions like India and Sri Lanka, where coconut farming is prevalent, making coir more accessible globally. Sisal is less abundant but favored in applications requiring durability, influencing its niche market presence and price premium.

Performance in Eco-Friendly Products

Sisal fibers offer superior tensile strength and durability compared to coir, making them ideal for eco-friendly products requiring long-lasting performance. Coir excels in water resistance and natural cushioning, suitable for biodegradable mats and upholstery. Both fibers provide sustainable alternatives, but sisal's robustness supports higher-stress applications in eco-conscious manufacturing.

Choosing Between Sisal and Coir Fiber

Sisal fiber, derived from the Agave sisalana plant, offers high durability, stiffness, and resistance to wear, making it ideal for heavy-use rugs and mats. Coir fiber, extracted from coconut husks, provides superior water resistance and softness, suitable for doormats and upholstery applications prone to moisture exposure. Selecting between sisal and coir depends on the required durability, environmental conditions, and desired texture for specific fiber applications.

Sisal vs Coir Infographic

materialdif.com

materialdif.com