Bast fibers, derived from the inner bark of plants like flax and hemp, offer high tensile strength and flexibility, making them ideal for textiles and ropes. Leaf fibers, sourced from the veins of plants such as sisal and abaca, provide coarse texture and durability suited for mats and brushes. Both fiber types contribute unique physical properties that influence their applications in sustainable and natural fiber industries.

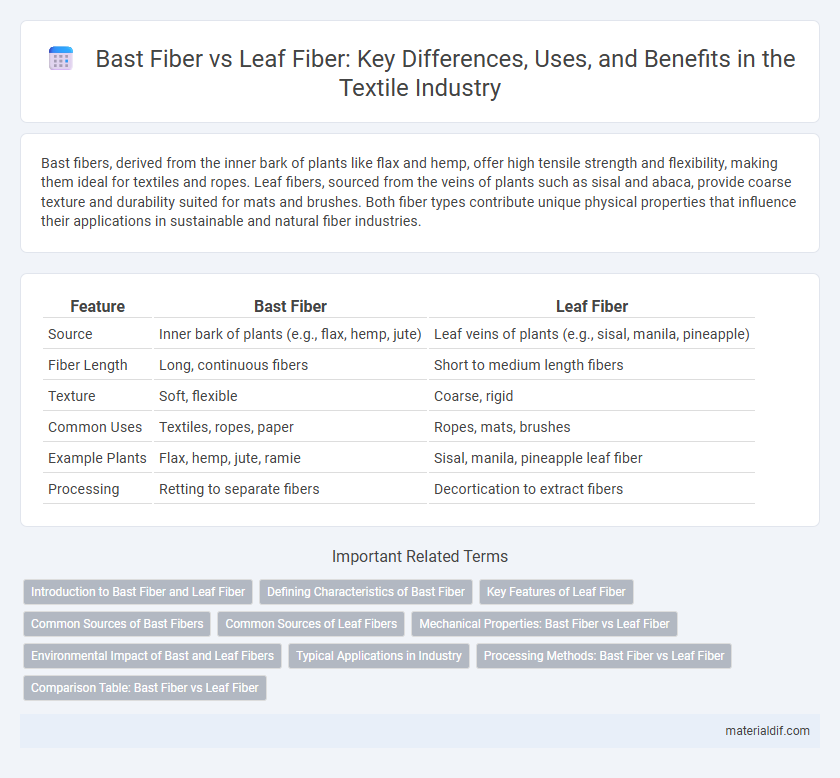

Table of Comparison

| Feature | Bast Fiber | Leaf Fiber |

|---|---|---|

| Source | Inner bark of plants (e.g., flax, hemp, jute) | Leaf veins of plants (e.g., sisal, manila, pineapple) |

| Fiber Length | Long, continuous fibers | Short to medium length fibers |

| Texture | Soft, flexible | Coarse, rigid |

| Common Uses | Textiles, ropes, paper | Ropes, mats, brushes |

| Example Plants | Flax, hemp, jute, ramie | Sisal, manila, pineapple leaf fiber |

| Processing | Retting to separate fibers | Decortication to extract fibers |

Introduction to Bast Fiber and Leaf Fiber

Bast fibers are obtained from the inner bark or phloem of plants such as flax, hemp, and jute, characterized by their high tensile strength and flexibility, making them ideal for textiles and ropes. Leaf fibers, derived from the vascular bundles of leaves like sisal and pineapple, are coarser and more rigid, commonly used in mats, brushes, and carpets. Both bast and leaf fibers serve distinct industrial applications due to their differing structural properties and fiber composition.

Defining Characteristics of Bast Fiber

Bast fiber, derived from the phloem or inner bark of plants like flax, hemp, and jute, is characterized by its long, strong, and flexible fibers, making it ideal for textiles and rope production. These fibers exhibit high tensile strength and good moisture absorption, contributing to durability and comfort in fabrics. Bast fibers differ from leaf fibers, which are shorter, coarser, and obtained from the vascular bundles of leaves, such as in sisal and abaca.

Key Features of Leaf Fiber

Leaf fiber, derived from the vascular bundles of monocot plants such as sisal and pineapple, features high tensile strength and coarse texture ideal for industrial applications like ropes and mats. Its long, fibrous strands exhibit excellent resistance to moisture and decomposition, making it durable in harsh environments. Unlike bast fiber, leaf fiber is less flexible but offers superior abrasion resistance, enhancing its suitability for heavy-duty uses.

Common Sources of Bast Fibers

Common sources of bast fibers include flax, hemp, jute, ramie, and kenaf, each extracted from the phloem or inner bark of dicotyledonous plants. These fibers are characterized by their long, strong, and flexible nature, making them ideal for textiles, ropes, and paper production. Bast fibers offer superior tensile strength compared to leaf fibers, which are primarily derived from monocot plants like sisal and abaca.

Common Sources of Leaf Fibers

Common sources of leaf fibers include sisal, abaca, and pineapple leaf fibers, which are extracted from the tough, fibrous leaves of specific plants. These fibers exhibit high tensile strength and durability, making them suitable for ropes, mats, brushes, and composite materials. Unlike bast fibers obtained from the inner stem bark, leaf fibers require different extraction methods, such as decortication, to separate the fibers from the surrounding leaf tissue.

Mechanical Properties: Bast Fiber vs Leaf Fiber

Bast fibers, derived from the outer stem of plants like flax and hemp, exhibit superior tensile strength and elasticity compared to leaf fibers such as sisal and abaca, which tend to be coarser and less flexible. The mechanical properties of bast fibers make them ideal for applications requiring high durability and resistance to mechanical stress, including textile manufacturing and composite reinforcement. Conversely, leaf fibers have higher lignin content, lending them greater rigidity but lower elongation at break, limiting their use in products needing flexibility.

Environmental Impact of Bast and Leaf Fibers

Bast fibers, derived from the inner bark of plants like flax, hemp, and jute, generally exhibit a lower environmental impact due to their renewable nature, biodegradability, and limited need for chemical processing. Leaf fibers, such as those from sisal and abaca, often require more intensive extraction methods and have higher water and energy consumption, contributing to a comparatively larger ecological footprint. Sustainable cultivation practices and efficient processing techniques are critical for minimizing the environmental impact of both bast and leaf fibers in the textile and composites industries.

Typical Applications in Industry

Bast fibers, derived from the external layer of plant stems such as flax, hemp, and jute, are widely used in textiles, composites, and automotive industries due to their strength and flexibility. Leaf fibers, obtained from the leaves of plants like sisal, pineapple, and agave, find typical applications in rope manufacturing, mats, brushes, and paper production because of their coarse texture and high durability. Both fiber types contribute significantly to sustainable material solutions in packaging, construction, and eco-friendly product development.

Processing Methods: Bast Fiber vs Leaf Fiber

Bast fiber is extracted from the inner bark of plants such as flax, hemp, and jute through retting, a process that involves microbial action or chemical treatment to separate the fibers from the woody core. Leaf fiber, sourced from plants like sisal and abaca, requires decortication, where mechanical or manual scraping removes the non-fibrous material to isolate the fibers. Bast fiber processing typically results in finer, stronger textiles, while leaf fiber processing produces coarser fibers used mainly for ropes and mats.

Comparison Table: Bast Fiber vs Leaf Fiber

Bast fibers, sourced from the inner bark of plants like flax and jute, offer superior tensile strength and flexibility compared to leaf fibers derived from plants such as sisal and abaca, which are coarser and more rigid. Bast fibers excel in applications requiring softness and durability, including textiles and ropes, while leaf fibers are preferred for industrial uses like mats and brushes due to their stiffness and resistance. The comparison table highlights key attributes: bast fibers have higher cellulose content and finer diameter, whereas leaf fibers exhibit greater lignin content and coarser texture.

Bast Fiber vs Leaf Fiber Infographic

materialdif.com

materialdif.com