PP fiber offers superior chemical resistance and higher durability compared to PET fiber, making it ideal for harsh environments. PET fiber provides better tensile strength and improved elasticity, resulting in enhanced flexibility and performance in applications requiring frequent bending. Choosing between PP and PET fiber depends on the specific requirements for strength, flexibility, and environmental exposure in fiber reinforcement projects.

Table of Comparison

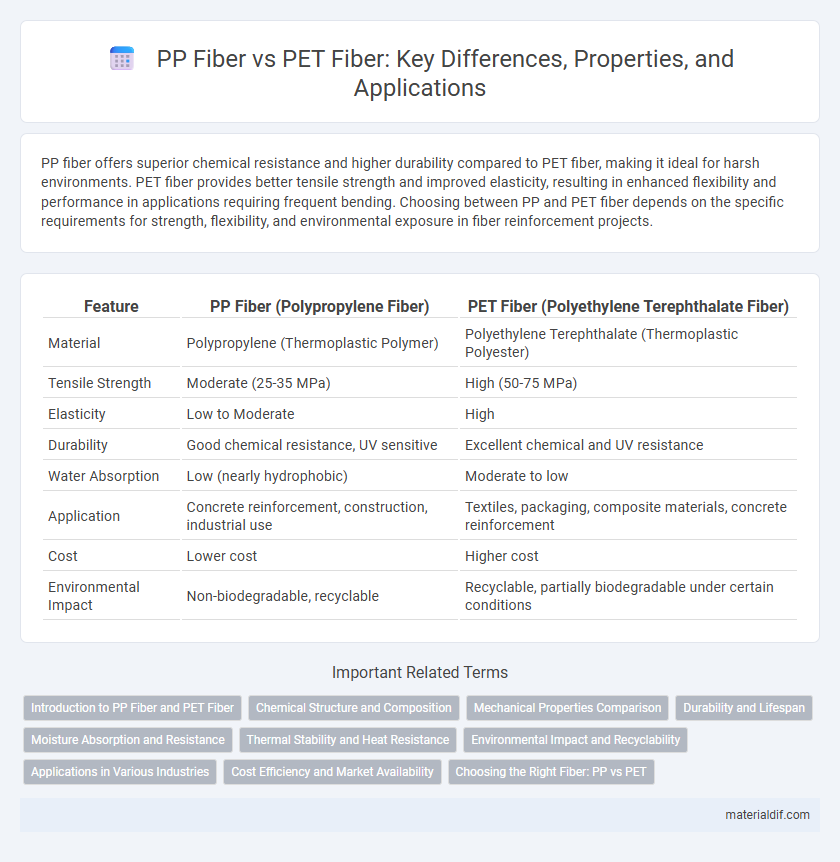

| Feature | PP Fiber (Polypropylene Fiber) | PET Fiber (Polyethylene Terephthalate Fiber) |

|---|---|---|

| Material | Polypropylene (Thermoplastic Polymer) | Polyethylene Terephthalate (Thermoplastic Polyester) |

| Tensile Strength | Moderate (25-35 MPa) | High (50-75 MPa) |

| Elasticity | Low to Moderate | High |

| Durability | Good chemical resistance, UV sensitive | Excellent chemical and UV resistance |

| Water Absorption | Low (nearly hydrophobic) | Moderate to low |

| Application | Concrete reinforcement, construction, industrial use | Textiles, packaging, composite materials, concrete reinforcement |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Non-biodegradable, recyclable | Recyclable, partially biodegradable under certain conditions |

Introduction to PP Fiber and PET Fiber

PP fiber, or polypropylene fiber, is a synthetic fiber widely used for concrete reinforcement due to its excellent chemical resistance, lightweight nature, and cost-effectiveness. PET fiber, derived from polyethylene terephthalate, offers higher tensile strength and better durability, making it suitable for high-performance applications like construction and textiles. Both fibers improve material properties, but PP fiber excels in crack control while PET fiber provides enhanced structural reinforcement.

Chemical Structure and Composition

PP fiber, or polypropylene fiber, is composed of long polymer chains consisting of repeated propylene monomers with a crystalline structure that offers chemical resistance and hydrophobic properties. PET fiber, or polyethylene terephthalate fiber, features a polyester chemical structure formed from repeating ethylene glycol and terephthalic acid units, providing higher tensile strength and thermal stability. The aromatic rings in PET's composition contribute to its rigidity and durability, distinguishing it from the aliphatic hydrocarbons in PP fiber which yield greater flexibility and chemical inertness.

Mechanical Properties Comparison

PP fiber offers high tensile strength and excellent impact resistance, making it suitable for reinforcing concrete and improving crack control. PET fiber provides superior durability with enhanced elongation at break and better resistance to chemical degradation, contributing to long-term structural stability. Both fibers show distinct mechanical properties where PP excels in flexibility and energy absorption, while PET demonstrates higher stiffness and abrasion resistance.

Durability and Lifespan

PP fiber offers excellent chemical resistance and retains its mechanical properties over extended periods, making it highly durable in concrete reinforcement. PET fiber demonstrates superior tensile strength and UV resistance, contributing to a longer lifespan in applications exposed to harsh environmental conditions. Both fibers enhance structural integrity but PET's enhanced durability under UV exposure often results in a prolonged service life compared to PP fiber.

Moisture Absorption and Resistance

PP fiber exhibits significantly lower moisture absorption compared to PET fiber, making it highly resistant to water penetration and ideal for damp environments. PET fiber tends to absorb more moisture, which can reduce its mechanical properties and durability over time. The superior moisture resistance of PP fiber enhances its performance in applications requiring long-term exposure to humidity and wet conditions.

Thermal Stability and Heat Resistance

PP fiber offers moderate thermal stability with a melting point around 160degC, making it suitable for applications requiring basic heat resistance. PET fiber exhibits higher thermal stability, melting near 250degC, which enhances its performance in environments with elevated temperatures. The superior heat resistance of PET fiber makes it preferable for industries demanding durability under thermal stress.

Environmental Impact and Recyclability

PP fiber exhibits a lower environmental impact due to its energy-efficient production process and high chemical resistance, which extends product lifespan. PET fiber offers superior recyclability, as it can be recycled multiple times into new fibers or plastic products, reducing landfill waste. Both fibers contribute to sustainability, but PET is favored in circular economy models for its closed-loop recycling capabilities.

Applications in Various Industries

PP fiber offers excellent chemical resistance and flexibility, making it ideal for concrete reinforcement in construction and automotive industries. PET fiber provides high tensile strength and durability, widely used in textiles, packaging, and filtration sectors. Both fibers enhance product performance, with PP favored for cost-effective solutions and PET preferred for heavy-duty applications.

Cost Efficiency and Market Availability

PP fiber offers superior cost efficiency compared to PET fiber due to its lower raw material and production costs, making it a preferred choice for large-scale construction projects. Market availability of PP fiber is generally higher, supported by extensive global manufacturing and distribution networks, whereas PET fiber, while offering enhanced durability and chemical resistance, often comes at a premium price and limited availability. Both fibers serve critical roles in concrete reinforcement, with PP fiber dominating budget-sensitive applications and PET fiber targeting specialized markets requiring enhanced performance attributes.

Choosing the Right Fiber: PP vs PET

Polypropylene (PP) fiber offers lightweight durability and excellent chemical resistance, making it ideal for concrete reinforcement in construction projects that require moisture and corrosion resistance. Polyester (PET) fiber provides superior tensile strength and UV stability, preferred for applications demanding enhanced mechanical performance and weather resistance. Selecting the right fiber depends on environmental exposure, load requirements, and cost considerations to optimize structural integrity and longevity.

PP Fiber vs PET Fiber Infographic

materialdif.com

materialdif.com