Resin Transfer Molding (RTM) offers superior precision and consistency compared to Hand Lay-up, enabling higher-quality fiber-reinforced composites with less waste. RTM involves injecting resin into a closed mold, enhancing fiber wet-out and reducing voids, while Hand Lay-up relies on manual application of resin and fibers, which can result in variability and slower production. Choosing RTM improves mechanical properties and scalability for advanced composite manufacturing.

Table of Comparison

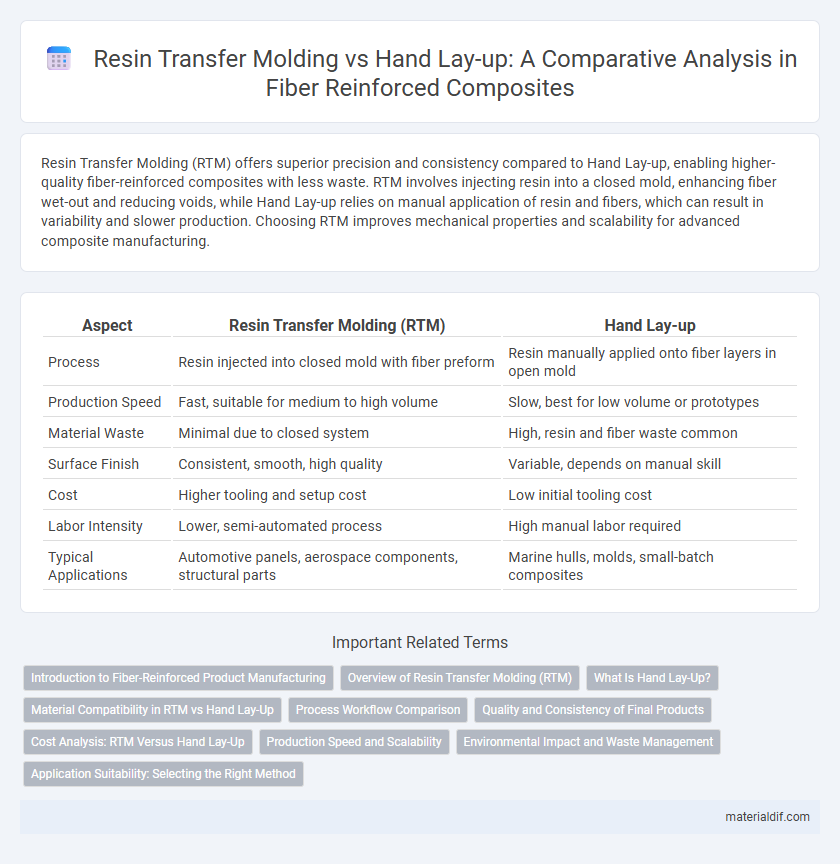

| Aspect | Resin Transfer Molding (RTM) | Hand Lay-up |

|---|---|---|

| Process | Resin injected into closed mold with fiber preform | Resin manually applied onto fiber layers in open mold |

| Production Speed | Fast, suitable for medium to high volume | Slow, best for low volume or prototypes |

| Material Waste | Minimal due to closed system | High, resin and fiber waste common |

| Surface Finish | Consistent, smooth, high quality | Variable, depends on manual skill |

| Cost | Higher tooling and setup cost | Low initial tooling cost |

| Labor Intensity | Lower, semi-automated process | High manual labor required |

| Typical Applications | Automotive panels, aerospace components, structural parts | Marine hulls, molds, small-batch composites |

Introduction to Fiber-Reinforced Product Manufacturing

Resin Transfer Molding (RTM) and Hand Lay-up are prominent techniques in fiber-reinforced product manufacturing, each offering distinct advantages for composite fabrication. RTM involves injecting resin into a closed mold containing dry fiber preforms, ensuring consistent fiber distribution and enhanced mechanical properties suitable for high-performance applications. In contrast, Hand Lay-up is a manual process where resin is applied directly to fiber layers, offering flexibility and cost-efficiency for low-volume production with simpler geometries.

Overview of Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a closed-mold composite manufacturing process where resin is injected under pressure into a mold cavity containing a fiber reinforcement preform. This technique offers high precision, consistent fiber-to-resin ratios, and improved surface finish compared to traditional hand lay-up methods. RTM enables efficient production of complex, high-strength fiber composites with enhanced mechanical properties and reduced material waste.

What Is Hand Lay-Up?

Hand lay-up is a traditional composite fabrication method where fiber reinforcements are manually placed into a mold and saturated with resin using brushes or rollers, allowing precise control over fiber orientation and resin distribution. This technique is widely used for producing large, complex shapes with moderate tooling costs and is favored for its simplicity and adaptability in low-volume production. Compared to resin transfer molding, hand lay-up typically requires longer curing times and may result in lower structural uniformity, but offers greater flexibility in material selection and repair.

Material Compatibility in RTM vs Hand Lay-Up

Resin Transfer Molding (RTM) offers enhanced material compatibility due to its ability to precisely control resin flow and curing conditions, ensuring uniform impregnation of complex fiber preforms. Hand Lay-up relies on manual application of resin, which can lead to inconsistent resin distribution and potential voids, limiting the effectiveness of some resin-fiber combinations. RTM's closed-mold process supports advanced thermosetting and thermoplastic resins, enabling higher fiber volume fractions and superior composite performance compared to the open-mold Hand Lay-up technique.

Process Workflow Comparison

Resin Transfer Molding (RTM) involves injecting resin into a closed mold containing fiber reinforcements, enabling precise control over resin distribution and reducing voids for high-quality composite parts. Hand Lay-up requires manually placing fiber layers and applying resin by brush or roller in an open mold, which is labor-intensive and prone to inconsistencies in fiber wet-out and thickness. RTM's automated, closed-process workflow delivers higher repeatability and efficient production cycles compared to the manual, time-consuming hand lay-up technique.

Quality and Consistency of Final Products

Resin Transfer Molding (RTM) delivers superior quality and consistency by precisely controlling resin flow and fiber placement, resulting in fewer voids and better fiber-resin bonding compared to Hand Lay-up. Hand Lay-up relies on manual techniques, leading to greater variability in fiber alignment, resin distribution, and thickness, which can cause uneven mechanical properties. RTM's automated process ensures repeatable, high-strength composite parts ideal for critical applications demanding stringent quality standards.

Cost Analysis: RTM Versus Hand Lay-Up

Resin Transfer Molding (RTM) typically involves higher initial capital investment due to mold and equipment costs but offers lower labor expenses and faster cycle times, resulting in cost efficiencies for medium to large production volumes. Hand Lay-up incurs minimal tooling costs but is labor-intensive and slower, making it less cost-effective for high-volume manufacturing despite lower upfront expenses. Overall, RTM presents better cost advantages in scalability and repeatability, while Hand Lay-up suits smaller, custom, or low-volume projects.

Production Speed and Scalability

Resin Transfer Molding (RTM) significantly outperforms Hand Lay-up in production speed due to its automated injection process, reducing cycle times to minutes compared to hours in manual lay-up. RTM offers superior scalability with consistent, high-quality output suitable for mass production, while Hand Lay-up remains best for low-volume, customized fiber-reinforced composites. Manufacturers aiming for rapid, repeatable manufacturing prefer RTM for efficient large-scale fiber composite production.

Environmental Impact and Waste Management

Resin Transfer Molding (RTM) significantly reduces environmental impact compared to Hand Lay-up by minimizing resin waste and emissions through closed molding processes that enhance material efficiency and reduce volatile organic compounds (VOCs). RTM enables better waste management by producing precise fiber-to-resin ratios, decreasing offcuts and scrap materials typical in Hand Lay-up, where excess resin and fiber waste are common due to manual layering. The controlled environment of RTM supports recycling initiatives and lowers hazardous waste generation, promoting eco-friendly composite manufacturing in industries like automotive and aerospace.

Application Suitability: Selecting the Right Method

Resin Transfer Molding (RTM) is ideal for high-volume production of complex, high-strength composite parts used in automotive and aerospace industries due to its precision and repeatability. Hand Lay-up suits low-volume, large-scale parts with simpler geometries, commonly applied in marine and construction sectors because of its cost-effectiveness and flexibility. Choosing between RTM and Hand Lay-up depends on balancing factors like production volume, part complexity, surface finish requirements, and overall budget.

Resin Transfer Molding vs Hand Lay-up Infographic

materialdif.com

materialdif.com