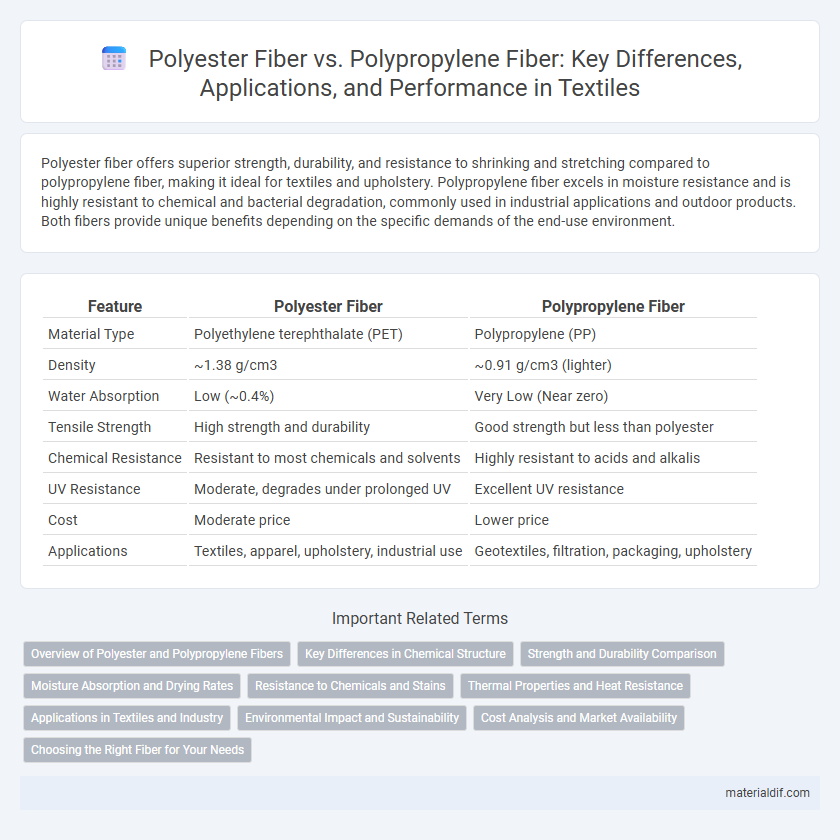

Polyester fiber offers superior strength, durability, and resistance to shrinking and stretching compared to polypropylene fiber, making it ideal for textiles and upholstery. Polypropylene fiber excels in moisture resistance and is highly resistant to chemical and bacterial degradation, commonly used in industrial applications and outdoor products. Both fibers provide unique benefits depending on the specific demands of the end-use environment.

Table of Comparison

| Feature | Polyester Fiber | Polypropylene Fiber |

|---|---|---|

| Material Type | Polyethylene terephthalate (PET) | Polypropylene (PP) |

| Density | ~1.38 g/cm3 | ~0.91 g/cm3 (lighter) |

| Water Absorption | Low (~0.4%) | Very Low (Near zero) |

| Tensile Strength | High strength and durability | Good strength but less than polyester |

| Chemical Resistance | Resistant to most chemicals and solvents | Highly resistant to acids and alkalis |

| UV Resistance | Moderate, degrades under prolonged UV | Excellent UV resistance |

| Cost | Moderate price | Lower price |

| Applications | Textiles, apparel, upholstery, industrial use | Geotextiles, filtration, packaging, upholstery |

Overview of Polyester and Polypropylene Fibers

Polyester fiber, derived from petroleum-based polymers, is known for its durability, chemical resistance, and moisture-wicking properties, making it a popular choice in textiles and industrial applications. Polypropylene fiber, a thermoplastic polymer, stands out for its lightweight nature, high tensile strength, and excellent resistance to abrasion and chemicals, frequently used in geotextiles and filtration products. Both fibers offer unique advantages in terms of strength, moisture resistance, and cost-effectiveness, influencing their selection based on specific performance requirements.

Key Differences in Chemical Structure

Polyester fiber consists of long-chain synthetic polymers primarily composed of terephthalic acid and ethylene glycol, forming strong ester bonds that provide durability and resistance to stretching. Polypropylene fiber is made from polymerized propylene monomers with a simple hydrocarbon structure, resulting in a lightweight, nonpolar fiber that offers excellent moisture resistance and chemical inertness. The key chemical difference lies in polyester's ester functional groups versus polypropylene's hydrocarbon chains, influencing their physical properties and applications.

Strength and Durability Comparison

Polyester fiber exhibits higher tensile strength and superior resistance to stretching compared to polypropylene fiber, making it ideal for applications requiring long-term durability. Polyester's robust molecular structure enhances its abrasion resistance and UV stability, whereas polypropylene tends to degrade faster under prolonged exposure to sunlight and mechanical stress. Consequently, polyester fiber maintains structural integrity and strength significantly better in demanding environments than polypropylene fiber.

Moisture Absorption and Drying Rates

Polyester fiber exhibits low moisture absorption, typically absorbing less than 0.4% of its weight in water, which contributes to its fast-drying properties and resistance to mildew. In contrast, polypropylene fiber absorbs virtually no moisture, making it even quicker to dry and highly resistant to water retention, ideal for moisture-prone environments. These differences in moisture absorption and drying rates impact their suitability for applications such as outdoor gear, upholstery, and industrial textiles.

Resistance to Chemicals and Stains

Polyester fiber exhibits superior resistance to chemicals such as acids and alkalis, maintaining its strength and appearance when exposed to harsh substances. Polypropylene fiber, while resistant to many chemicals, is particularly effective against stains from oils and grease due to its non-polar molecular structure. These characteristics make polyester fiber ideal for applications requiring durability against chemical exposure, whereas polypropylene fiber excels in environments prone to oily or greasy contamination.

Thermal Properties and Heat Resistance

Polyester fiber exhibits higher thermal stability with a melting point around 260degC, making it suitable for applications requiring moderate heat resistance. Polypropylene fiber has a lower melting point near 160degC but offers superior heat insulation due to its low thermal conductivity. Both fibers differ significantly in thermal degradation thresholds, influencing their performance in high-temperature environments.

Applications in Textiles and Industry

Polyester fiber offers superior durability, resistance to shrinking, and vibrant dye retention, making it ideal for apparel, upholstery, and industrial fabrics requiring long-lasting performance. Polypropylene fiber excels in moisture-wicking, chemical resistance, and lightweight properties, widely used in medical textiles, geotextiles, and filtration applications. The choice between polyester and polypropylene fibers depends on specific industry demands such as tensile strength, thermal stability, and environmental exposure.

Environmental Impact and Sustainability

Polyester fiber, derived from petroleum, has a higher carbon footprint and is less biodegradable compared to polypropylene fiber, which is also petroleum-based but generally considered less energy-intensive to produce. Polypropylene fiber's lower density contributes to reduced transportation emissions, enhancing its environmental profile. Both fibers face challenges in end-of-life management, with recycling options more established for polyester, making it marginally more sustainable despite its environmental drawbacks.

Cost Analysis and Market Availability

Polyester fiber generally offers a cost advantage over polypropylene fiber due to its widespread manufacturing processes and economies of scale, making it more accessible in global markets. Polypropylene fiber, while often more expensive per unit, provides specific benefits in chemical resistance and moisture wicking, limiting its market availability to niche industrial applications. Market trends show polyester fiber dominating sectors such as textiles and packaging, whereas polypropylene fibers see selective use in filtration and geotextiles, influencing their respective price points and distribution channels.

Choosing the Right Fiber for Your Needs

Polyester fiber offers high durability, excellent resistance to shrinking and stretching, and vibrant color retention, making it ideal for apparel and upholstery applications requiring strength and aesthetic appeal. Polypropylene fiber, known for its superior moisture-wicking properties, chemical resistance, and lightweight nature, excels in industrial uses such as geotextiles, filtration, and packaging. Selecting the right fiber depends on specific requirements like environmental exposure, mechanical performance, and cost-effectiveness to ensure optimal functionality and longevity.

Polyester Fiber vs Polypropylene Fiber Infographic

materialdif.com

materialdif.com