Ramie fiber offers superior strength and durability compared to jute fiber, making it ideal for textiles requiring long-lasting wear. While jute fiber is more affordable and biodegradable, its coarse texture limits its use to packaging and upholstery. Ramie's smooth, lustrous appearance enhances fabric quality, providing better moisture absorption and resistance to bacterial growth.

Table of Comparison

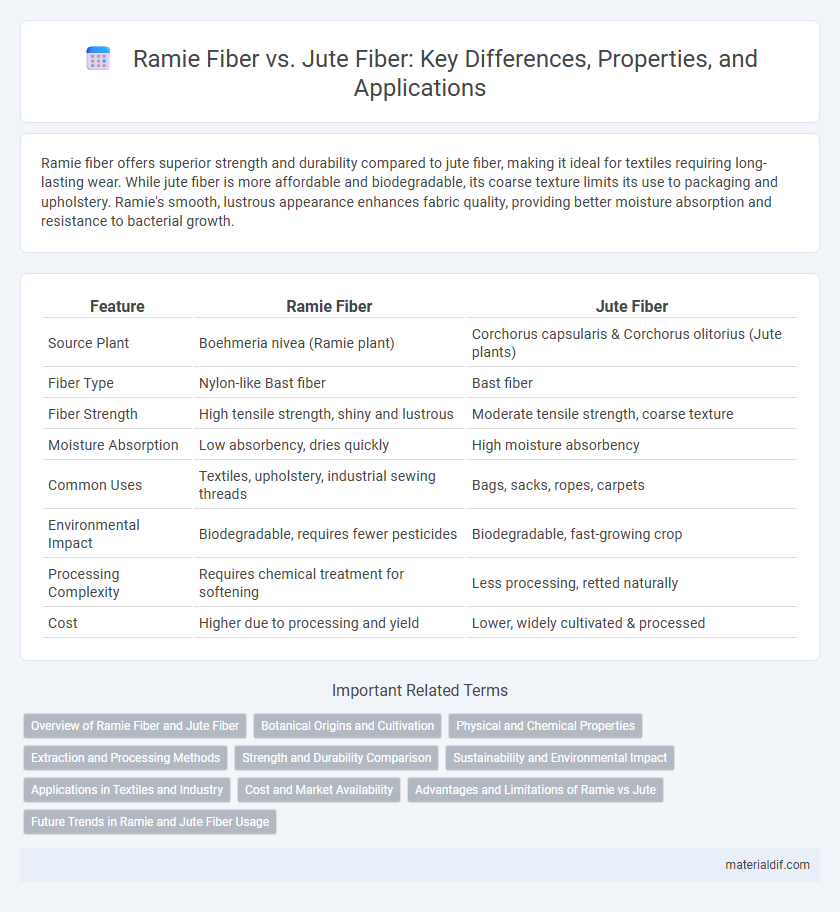

| Feature | Ramie Fiber | Jute Fiber |

|---|---|---|

| Source Plant | Boehmeria nivea (Ramie plant) | Corchorus capsularis & Corchorus olitorius (Jute plants) |

| Fiber Type | Nylon-like Bast fiber | Bast fiber |

| Fiber Strength | High tensile strength, shiny and lustrous | Moderate tensile strength, coarse texture |

| Moisture Absorption | Low absorbency, dries quickly | High moisture absorbency |

| Common Uses | Textiles, upholstery, industrial sewing threads | Bags, sacks, ropes, carpets |

| Environmental Impact | Biodegradable, requires fewer pesticides | Biodegradable, fast-growing crop |

| Processing Complexity | Requires chemical treatment for softening | Less processing, retted naturally |

| Cost | Higher due to processing and yield | Lower, widely cultivated & processed |

Overview of Ramie Fiber and Jute Fiber

Ramie fiber, derived from the stalks of the Boehmeria plant, is known for its exceptional strength, silky luster, and resistance to bacterial attack, making it ideal for blending with other textiles. Jute fiber, extracted from the Corchorus plant, is coarse, affordable, and widely used for packaging, ropes, and eco-friendly products due to its biodegradability and high tensile strength. Both fibers are natural bast fibers, but ramie offers superior durability and sheen, while jute is more cost-effective and commonly used in industrial applications.

Botanical Origins and Cultivation

Ramie fiber is derived from the plant Boehmeria nivea, a flowering plant in the nettle family native to East Asia, thriving in warm, humid climates with rich, well-drained soil. Jute fiber originates from Corchorus species, mainly Corchorus olitorius and Corchorus capsularis, cultivated extensively in the Bengal region of India and Bangladesh, favoring tropical climates with substantial rainfall and moist alluvial soil. Both fibers require specific agricultural conditions but differ significantly in their botanical classification and regional cultivation practices.

Physical and Chemical Properties

Ramie fiber exhibits higher tensile strength and greater resistance to bacterial attacks compared to jute fiber, making it more durable in various applications. Chemically, ramie contains a higher cellulose content (up to 85%) and lower lignin levels than jute, resulting in a finer texture and better moisture absorption. Both fibers are biodegradable and eco-friendly, but ramie's superior whiteness and resistance to mildew enhance its versatility in textile manufacturing.

Extraction and Processing Methods

Ramie fiber is extracted through a labor-intensive process of peeling the stalks and retting them in water to separate the fibers, followed by drying and beating to remove the gummy substances. Jute fiber undergoes a simpler water-retting process where stalks are submerged in water for microbial action to loosen the fibers, then stripped and washed. Ramie's processing requires chemical treatments to degum the fibers, while jute fibers are typically processed with minimal chemical intervention, making jute extraction more environmentally friendly.

Strength and Durability Comparison

Ramie fiber exhibits higher tensile strength and greater resistance to stretching compared to jute fiber, making it more suitable for applications requiring durability. Jute fiber, while strong, tends to degrade faster when exposed to moisture and sunlight, reducing its lifespan in outdoor or humid environments. Ramie's superior strength and resistance to environmental factors contribute to its longer-lasting performance in textiles and industrial materials.

Sustainability and Environmental Impact

Ramie fiber boasts higher tensile strength and faster growth rates, allowing for more sustainable cultivation with reduced pesticide requirements compared to jute fiber. Jute fiber, however, benefits from biodegradable properties and low-water cultivation but often depends on chemical retting processes that can harm aquatic ecosystems. Prioritizing ramie fiber supports eco-friendly textile production through lower environmental impact and efficient land use.

Applications in Textiles and Industry

Ramie fiber, known for its silky luster and high tensile strength, is extensively used in textile applications such as blending with cotton for lightweight clothing and upholstery fabrics, offering durability and moisture absorption. Jute fiber, characterized by its coarse texture and biodegradability, finds significant industrial use in making sacks, ropes, and carpet backing, as well as eco-friendly packaging materials. Both fibers contribute to sustainable textile production, with ramie preferred for fine textiles and jute dominating in heavy-duty industrial products.

Cost and Market Availability

Ramie fiber typically costs more than jute fiber due to its more labor-intensive extraction and processing methods, making it less economically feasible for large-scale applications. Jute fiber benefits from widespread cultivation in countries like India and Bangladesh, ensuring higher market availability and lower prices driven by large-scale production. The lower cost and abundant supply of jute fibers dominate markets where affordability and accessibility are critical for textile and packaging industries.

Advantages and Limitations of Ramie vs Jute

Ramie fiber offers superior strength, durability, and resistance to mildew compared to jute fiber, making it ideal for high-quality textiles and industrial applications. However, ramie fibers require extensive processing and are less elastic, limiting their use in flexible products where jute's natural coarseness and affordability provide advantages. Jute fiber excels in eco-friendliness and cost-effectiveness, but its lower tensile strength and susceptibility to moisture restrict durability and lifespan compared to ramie.

Future Trends in Ramie and Jute Fiber Usage

Ramie fiber, known for its strength and luster, is gaining traction in eco-friendly textile markets due to its biodegradability and compatibility with organic dyes, which aligns with increasing consumer demand for sustainable materials. Jute fiber continues to dominate in packaging and geotextile applications driven by its low cost and high tensile strength, but innovations in jute composites for automotive and construction industries signal expanding industrial use. Future trends indicate integrated uses of both ramie and jute fibers in hybrid textiles and biodegradable composites, propelled by advancements in fiber processing technologies and growing global emphasis on reducing plastic waste.

Ramie Fiber vs Jute Fiber Infographic

materialdif.com

materialdif.com