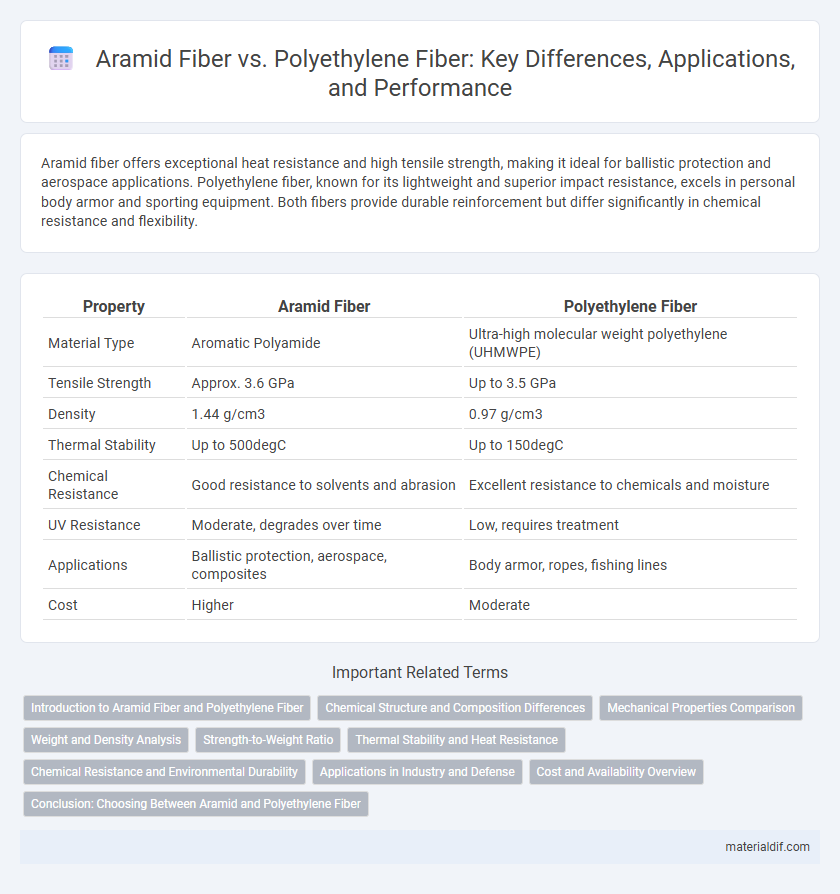

Aramid fiber offers exceptional heat resistance and high tensile strength, making it ideal for ballistic protection and aerospace applications. Polyethylene fiber, known for its lightweight and superior impact resistance, excels in personal body armor and sporting equipment. Both fibers provide durable reinforcement but differ significantly in chemical resistance and flexibility.

Table of Comparison

| Property | Aramid Fiber | Polyethylene Fiber |

|---|---|---|

| Material Type | Aromatic Polyamide | Ultra-high molecular weight polyethylene (UHMWPE) |

| Tensile Strength | Approx. 3.6 GPa | Up to 3.5 GPa |

| Density | 1.44 g/cm3 | 0.97 g/cm3 |

| Thermal Stability | Up to 500degC | Up to 150degC |

| Chemical Resistance | Good resistance to solvents and abrasion | Excellent resistance to chemicals and moisture |

| UV Resistance | Moderate, degrades over time | Low, requires treatment |

| Applications | Ballistic protection, aerospace, composites | Body armor, ropes, fishing lines |

| Cost | Higher | Moderate |

Introduction to Aramid Fiber and Polyethylene Fiber

Aramid fiber, known for its exceptional strength-to-weight ratio and high thermal stability, is widely used in aerospace, military, and industrial applications requiring durable and heat-resistant materials. Polyethylene fiber, particularly ultra-high-molecular-weight polyethylene (UHMWPE), offers outstanding impact resistance, lightweight properties, and chemical resistance, making it ideal for ballistic protection and rope manufacturing. Both fibers provide unique performance advantages in advanced composite materials, with aramid excelling in heat resistance and polyethylene in toughness and chemical inertness.

Chemical Structure and Composition Differences

Aramid fiber consists of aromatic polyamide chains characterized by rigid molecular structures with benzene rings and amide linkages, providing high thermal stability and mechanical strength. Polyethylene fiber is composed of long chains of ethylene monomers, forming non-polar hydrocarbon structures that offer exceptional toughness and chemical resistance. The aromatic rings in aramid fibers impart superior heat resistance, whereas polyethylene's simple hydrocarbon chains result in lower density and enhanced flexibility.

Mechanical Properties Comparison

Aramid fiber exhibits superior tensile strength and high modulus, making it ideal for applications requiring exceptional impact resistance and durability. Polyethylene fiber, particularly ultra-high-molecular-weight polyethylene (UHMWPE), offers outstanding abrasion resistance and excellent strength-to-weight ratio but generally has lower thermal stability than aramid. Both fibers provide significant mechanical advantages, with aramid excelling in heat resistance and polyethylene favoring lightweight flexibility.

Weight and Density Analysis

Aramid fibers typically have a density around 1.44 g/cm3, making them heavier than polyethylene fibers, which have a lower density near 0.97 g/cm3. The lower density of polyethylene fibers translates to significantly lighter weight materials, ideal for applications requiring weight reduction. Despite the higher density, aramid fibers offer superior strength-to-weight ratios, balancing weight with enhanced durability in high-performance uses.

Strength-to-Weight Ratio

Aramid fiber, known for its exceptional tensile strength and heat resistance, offers a high strength-to-weight ratio ideal for ballistic protection and aerospace applications. Polyethylene fiber, especially ultra-high-molecular-weight polyethylene (UHMWPE), surpasses aramid in strength-to-weight ratio with superior impact resistance and lighter weight, favoring sports equipment and personal armor. Both fibers provide unique advantages depending on specific performance requirements, with polyethylene excelling in lightweight durability and aramid delivering thermal stability.

Thermal Stability and Heat Resistance

Aramid fibers exhibit superior thermal stability withstanding continuous use temperatures up to 500degC, making them ideal for high-heat applications. Polyethylene fibers, such as UHMWPE, have lower thermal resistance, typically degrading around 150degC, limiting their use in elevated temperature environments. The inherent heat resistance of aramid fibers ensures durability and safety in protective gear and aerospace components compared to the lower thermal threshold of polyethylene fibers.

Chemical Resistance and Environmental Durability

Aramid fiber exhibits superior chemical resistance against acids, alkalis, and solvents compared to polyethylene fiber, making it ideal for harsh chemical environments. Polyethylene fiber offers excellent environmental durability with high resistance to UV radiation and moisture, which ensures prolonged performance in outdoor applications. The differing chemical stability and environmental resilience between aramid and polyethylene fibers influence their suitability for specific industrial and protective uses.

Applications in Industry and Defense

Aramid fiber exhibits exceptional heat resistance and high tensile strength, making it ideal for ballistic armor, aerospace materials, and reinforced composites in defense and industrial applications. Polyethylene fiber, known for its ultra-high molecular weight and lightweight nature, excels in personal protective equipment, marine ropes, and lightweight ballistic helmets used in military and industrial environments. Both fibers provide critical solutions in safety and durability, with aramid prioritized for thermal stability and polyethylene favored for superior impact resistance and versatility.

Cost and Availability Overview

Aramid fiber generally has a higher cost compared to polyethylene fiber due to its complex manufacturing process and superior heat resistance properties. Polyethylene fiber is more widely available and cost-effective, especially in bulk applications where budget constraints are significant. The difference in price and accessibility makes polyethylene fiber a preferred choice for large-scale industrial uses, while aramid fiber suits specialized applications requiring enhanced strength and durability.

Conclusion: Choosing Between Aramid and Polyethylene Fiber

Aramid fiber offers exceptional heat resistance, high tensile strength, and excellent durability, making it ideal for applications requiring impact resistance and thermal stability, such as ballistic armor and aerospace components. Polyethylene fiber provides superior chemical resistance, lightweight properties, and outstanding abrasion resistance, suited for marine environments, ropes, and protective clothing. Selecting between aramid and polyethylene fibers depends on the specific performance needs, where aramid excels in thermal and structural strength, while polyethylene is preferred for chemical resistance and lightweight flexibility.

Aramid Fiber vs Polyethylene Fiber Infographic

materialdif.com

materialdif.com