PLA fiber, derived from renewable resources such as corn starch, offers biodegradability and a lower carbon footprint compared to conventional PET fiber, which is petroleum-based and widely used for its durability and water resistance. While PLA fiber excels in eco-friendliness and compostability, PET fiber outperforms PLA in mechanical strength and heat resistance, making it suitable for high-performance applications. Selecting between PLA and PET fibers depends on balancing environmental impact with functional requirements in textile and packaging industries.

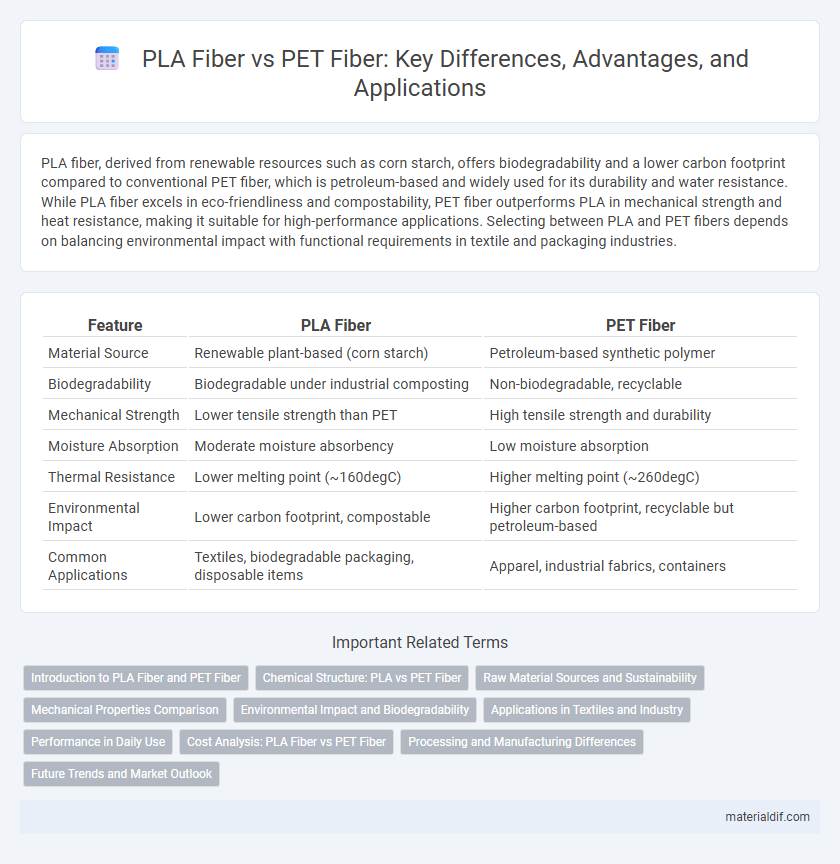

Table of Comparison

| Feature | PLA Fiber | PET Fiber |

|---|---|---|

| Material Source | Renewable plant-based (corn starch) | Petroleum-based synthetic polymer |

| Biodegradability | Biodegradable under industrial composting | Non-biodegradable, recyclable |

| Mechanical Strength | Lower tensile strength than PET | High tensile strength and durability |

| Moisture Absorption | Moderate moisture absorbency | Low moisture absorption |

| Thermal Resistance | Lower melting point (~160degC) | Higher melting point (~260degC) |

| Environmental Impact | Lower carbon footprint, compostable | Higher carbon footprint, recyclable but petroleum-based |

| Common Applications | Textiles, biodegradable packaging, disposable items | Apparel, industrial fabrics, containers |

Introduction to PLA Fiber and PET Fiber

PLA fiber, derived from renewable resources like cornstarch, offers biodegradability, low carbon footprint, and compostability, making it a sustainable alternative for textile and packaging applications. PET fiber, synthesized from petroleum-based polymers, is known for its high strength, durability, and resistance to moisture and chemicals, used extensively in apparel, industrial fabrics, and containers. Both fibers serve distinct market needs, with PLA emphasizing environmental benefits and PET prioritizing performance and longevity.

Chemical Structure: PLA vs PET Fiber

PLA fiber is composed of polylactic acid, a biodegradable aliphatic polyester derived from renewable resources like corn starch, characterized by ester functional groups and a chiral center in its chemical structure. PET fiber consists of polyethylene terephthalate, a synthetic aromatic polyester formed from terephthalic acid and ethylene glycol, featuring rigid benzene rings that provide high mechanical strength and thermal stability. The chemical structure of PLA offers biodegradability and lower melting points, while PET's aromatic backbone delivers superior durability and resistance to environmental degradation.

Raw Material Sources and Sustainability

PLA fiber is derived from renewable resources such as corn starch or sugarcane, making it biodegradable and compostable, which enhances its sustainability profile. PET fiber, on the other hand, is produced from non-renewable petroleum-based raw materials, resulting in a higher environmental footprint due to fossil fuel extraction and processing. The renewable origin of PLA fiber supports circular economy goals and reduces dependence on finite resources compared to the synthetic production of PET fiber.

Mechanical Properties Comparison

PLA fiber exhibits higher tensile strength but lower elongation at break compared to PET fiber, making it more rigid but less flexible. PET fiber offers superior impact resistance and greater durability under repetitive stress due to its excellent fatigue resistance. These mechanical property differences influence their suitability for applications requiring either stiffness and biodegradability (PLA) or toughness and long-term performance (PET).

Environmental Impact and Biodegradability

PLA fiber, derived from renewable resources like corn starch, offers significant environmental benefits due to its biodegradability and compostability, breaking down naturally within months under industrial composting conditions. In contrast, PET fiber, synthesized from non-renewable petroleum, poses environmental challenges as it is non-biodegradable and persists in ecosystems for decades, contributing to microplastic pollution. The sustainable lifecycle of PLA fiber reduces landfill waste and carbon emissions compared to PET fiber, making it a preferable choice for eco-conscious textile and packaging applications.

Applications in Textiles and Industry

PLA fiber offers superior biodegradability and moisture-wicking properties, making it ideal for eco-friendly textile applications like activewear and medical fabrics. PET fiber excels in durability, tensile strength, and resistance to chemicals, driving its widespread use in industrial textiles such as conveyor belts, tire reinforcements, and upholstery. Both fibers serve critical roles, with PLA favored for sustainable fashion and PET dominating in heavy-duty industrial applications.

Performance in Daily Use

PLA fiber exhibits excellent moisture-wicking properties and biodegradability, making it ideal for eco-friendly daily wear, while PET fiber offers superior durability, wrinkle resistance, and tensile strength, enhancing long-term garment performance. PET fiber excels in abrasion resistance and maintains its shape well under repeated washing, whereas PLA fiber may degrade faster in humid or high-heat conditions. Choosing between PLA and PET fibers depends on prioritizing sustainability and comfort versus strength and longevity in daily use.

Cost Analysis: PLA Fiber vs PET Fiber

PLA fiber generally incurs higher production costs than PET fiber due to its bioplastic raw materials derived from renewable resources like corn starch, compared to petroleum-based PET fibers. PET fiber benefits from established mass production processes and economies of scale, resulting in lower market prices and widespread availability. Despite PLA's premium price, its biodegradability and eco-friendly properties can offset costs in sustainable applications requiring reduced environmental impact.

Processing and Manufacturing Differences

PLA fiber is derived from renewable resources using a fermentation process that converts plant starches into lactic acid, followed by polymerization and fiber spinning under controlled temperature conditions. PET fiber production involves petrochemical-based raw materials synthesized through polycondensation, requiring higher processing temperatures and extrusion techniques to achieve its crystalline structure. The manufacturing of PLA fibers generally demands lower melting points and less energy input compared to PET fibers, influencing production speed and environmental impact.

Future Trends and Market Outlook

PLA fiber, derived from renewable plant-based resources, is poised for significant growth due to increasing demand for sustainable and biodegradable materials in the textile and packaging industries. PET fiber, known for its durability and recyclability, continues to dominate the market but faces rising competition from bio-based alternatives amid tightening environmental regulations. Future trends indicate a growing integration of PLA fibers in eco-friendly product lines, supported by advancements in bio-polymers and consumer preference shifts towards circular economy models.

PLA fiber vs PET fiber Infographic

materialdif.com

materialdif.com